A four-pole armature

A technology of armature and pole electricity, which is applied in the field of four-pole armature, can solve problems such as wear, ablation, and influence on the reliability of electromagnetic emission, and achieve lower processing accuracy requirements, improved contact area and contact efficiency, and pressure distribution on the contact surface uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

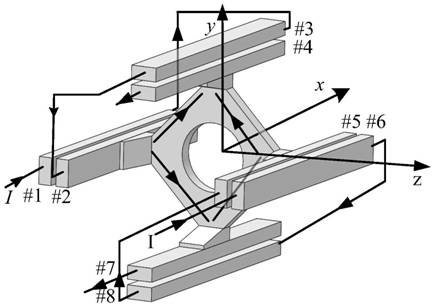

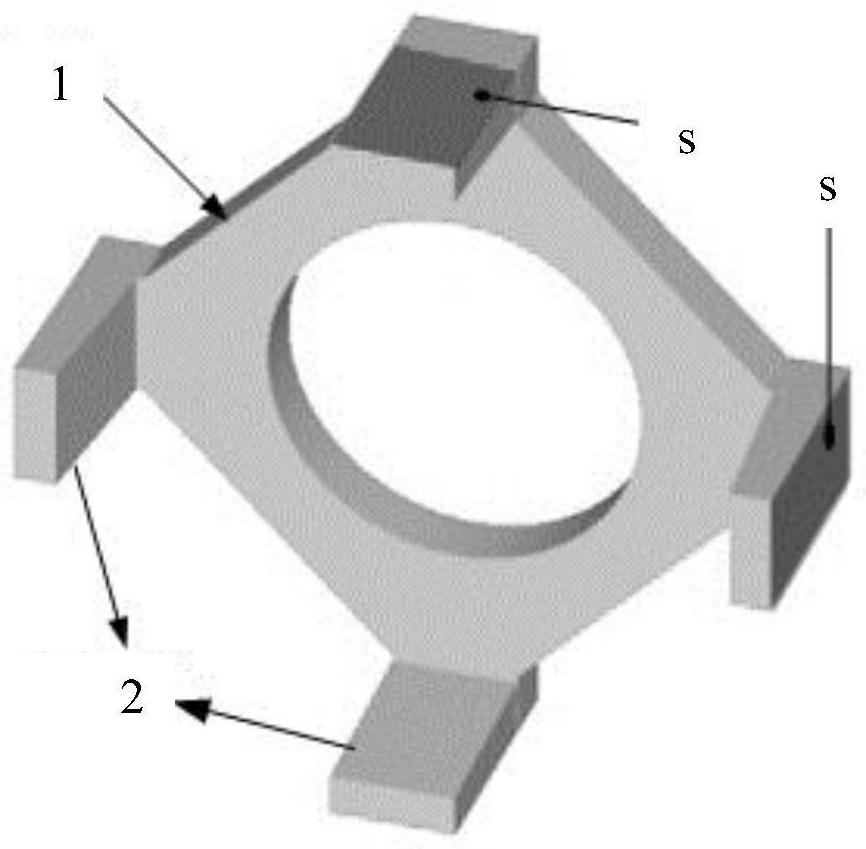

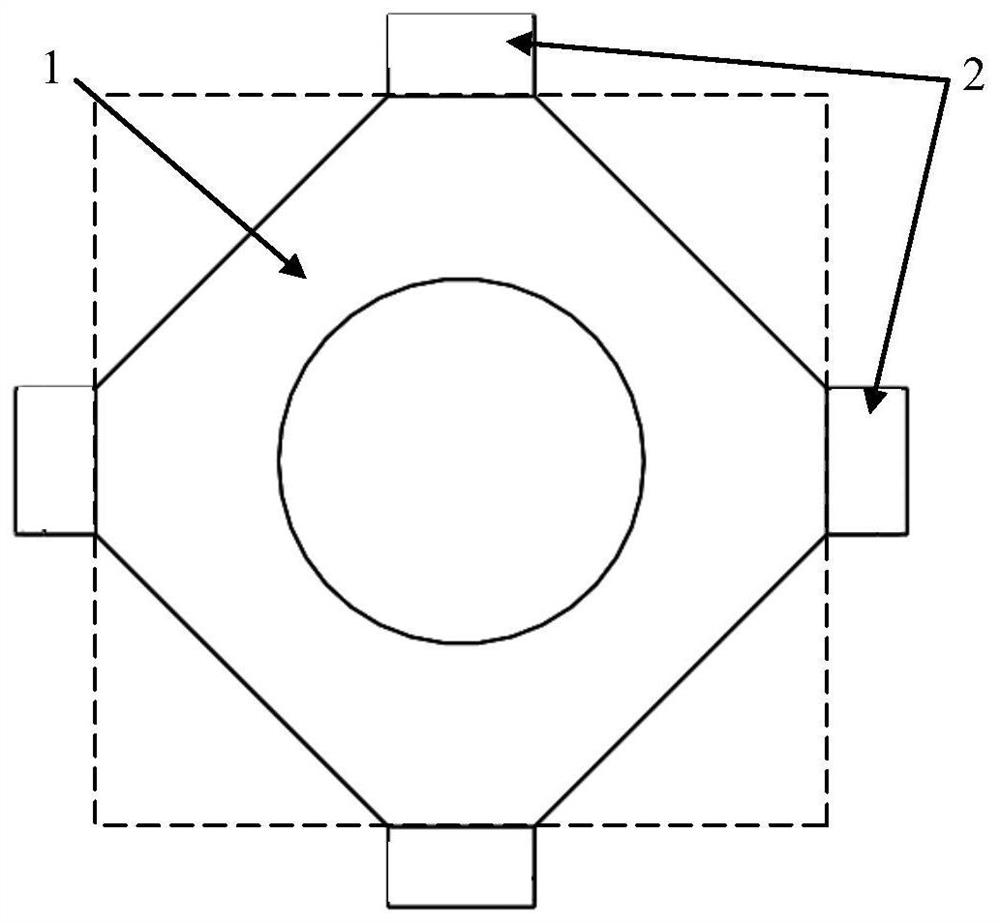

[0044] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the armature of this embodiment includes an armature body 1 and an armature cantilever 2 connected to the armature body 1 . The armature body 1 is an octagonal block, and a through hole (not labeled) is arranged in the center of the armature body 1 . The armature cantilever 2 is a flexible arm, and the four armature cantilever 2 are respectively connected to two opposite sides of the armature body 1. The armature cantilever 2 moves from the front end of the armature body 1 along the extending backwards in a parallel direction. For ease of description, the end of the armature cantilever 2 connected to the armature body 1 is defined as the head, then the free end of the armature cantilever 2 is the tail, and the head of the armature cantilever 2 is connected to the front end of the armature body 1. flush. The armature cantilever 2 has a contact surface s that is in sliding contact with the track in the...

Embodiment 2

[0049] Figure 8 , Figure 9 , Figure 10 and Figure 11 It is a schematic structural diagram of the armature cantilever according to Embodiment 2 of the present invention. The difference between this embodiment and Embodiment 1 is: the contact surface s where the armature cantilever 2 contacts the track is a curved surface, that is, the outline of the contact surface s is curved, and the front end point of the curve is between the axis of the armature body 1. The difference between the distance between the curve and the distance between the end point of the curve and the axis of the armature body 1 is the interference amount t of the armature cantilever r (the contact surface is an inclined plane in embodiment 1, then the profile of the contact surface is linear, and the amount of interference t r is the difference between the distance between the front end point of the straight line and the axis of the armature body 1 and the distance between the end point of the straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com