Dismantle-free cleaning composition for automotive engine lubricating system sludge and preparation method and application thereof

A technology of automobile engine and cleaning composition, applied in the field of cleaning, can solve the problems of inability to discharge waste lubricating oil, pollute lubricating oil products, and difficult to dissolve oil sludge, and achieves improved carbon deposition and sludge removal rate, good anti-wear reduction and other problems. The effect of friction and good dispersing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate those skilled in the art to understand the solution of the present invention, the solution of the present invention will be further described below in conjunction with specific examples. It should be understood that the embodiments of the present invention are explanations of the solution of the present invention, and are not intended to limit the protection scope of the present invention.

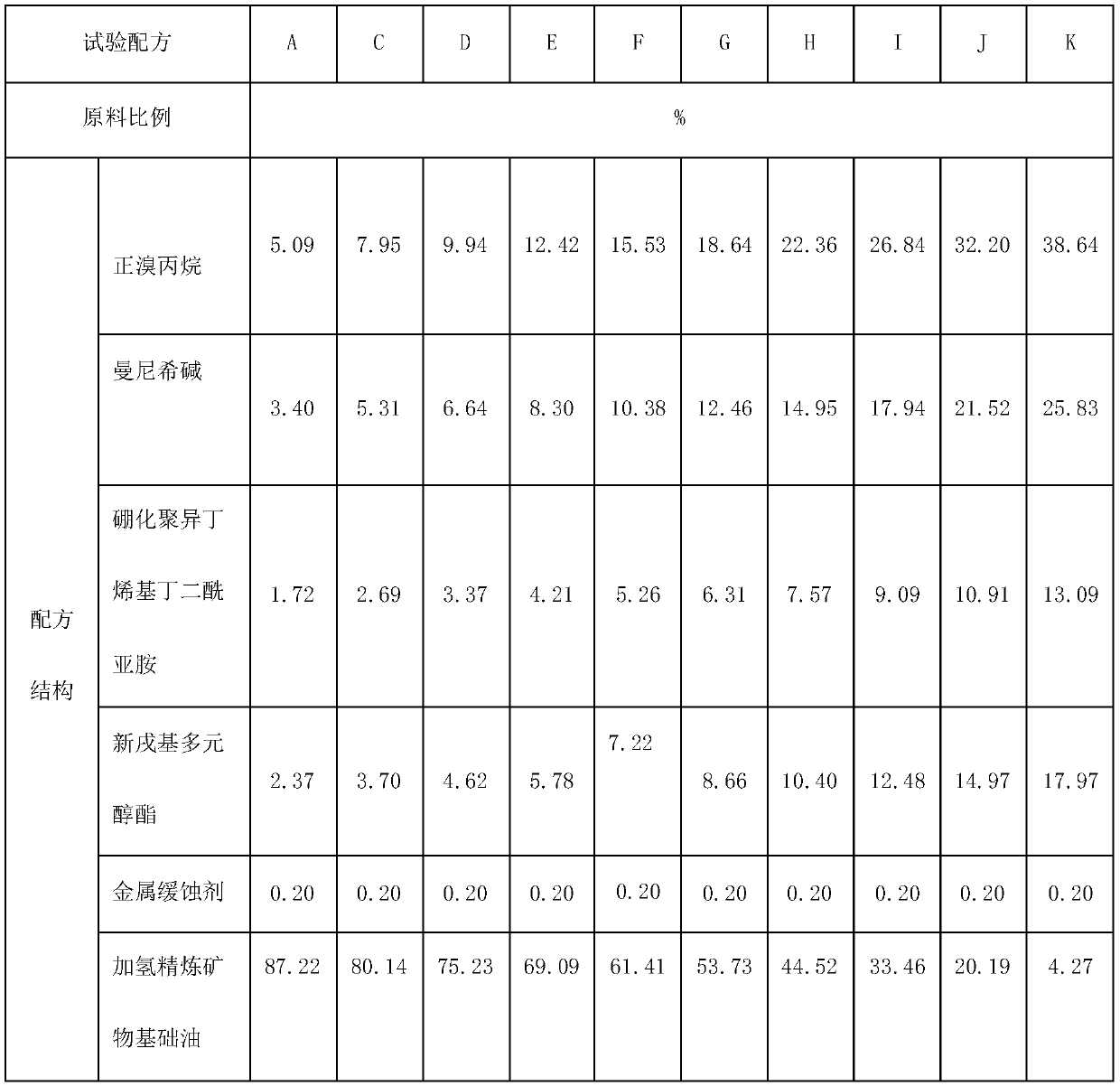

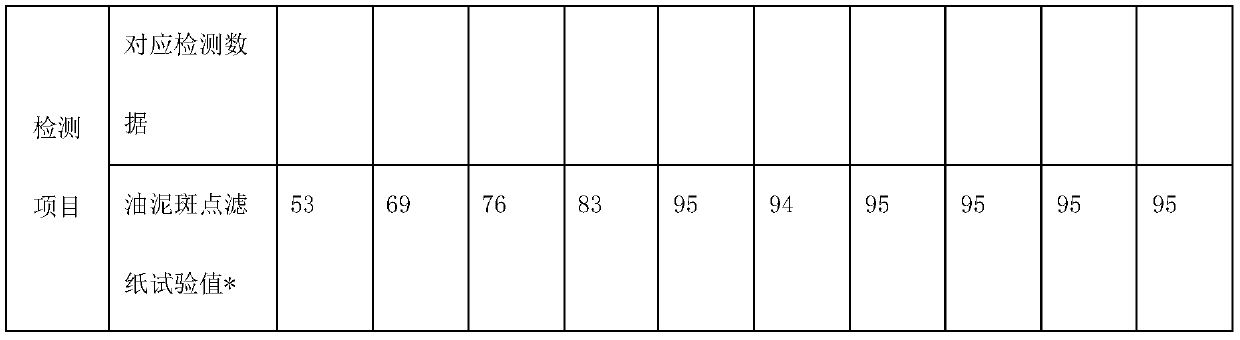

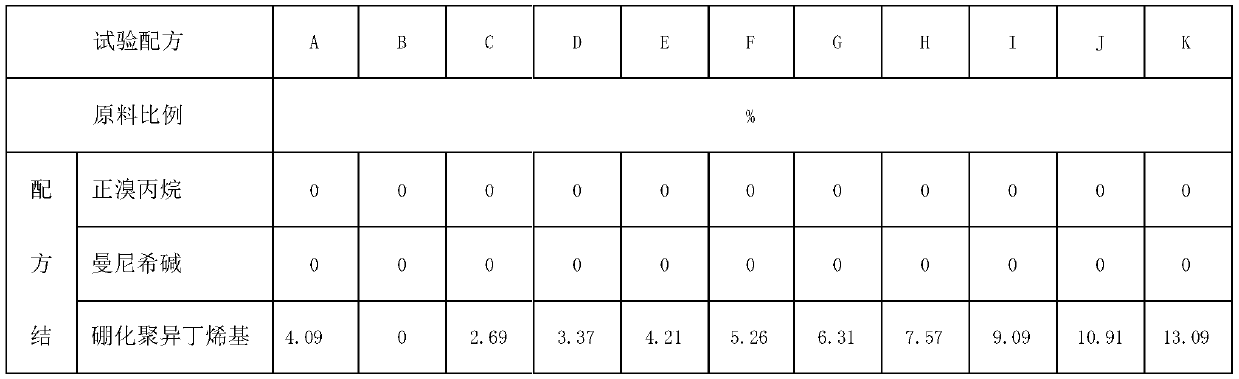

[0026] An embodiment of the present invention provides a composition for cleaning automobile engine lubrication system oil sludge without dismantling. According to the mass percentage, the composition includes the following components:

[0027] N-bromopropane 2-35%;

[0028] Mannich base 2-35%;

[0029] Borated polyisobutenyl succinimide 2-35%;

[0030] Neopentyl polyol ester 5-80%;

[0031] Metal corrosion inhibitor 0-0.2%;

[0032] The balance is mineral base oil.

[0033] In some strengths of the present invention, the mass percentage of n-bromopropane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear scar diameter | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com