A kind of method of unsaturated fatty acid decarboxylation

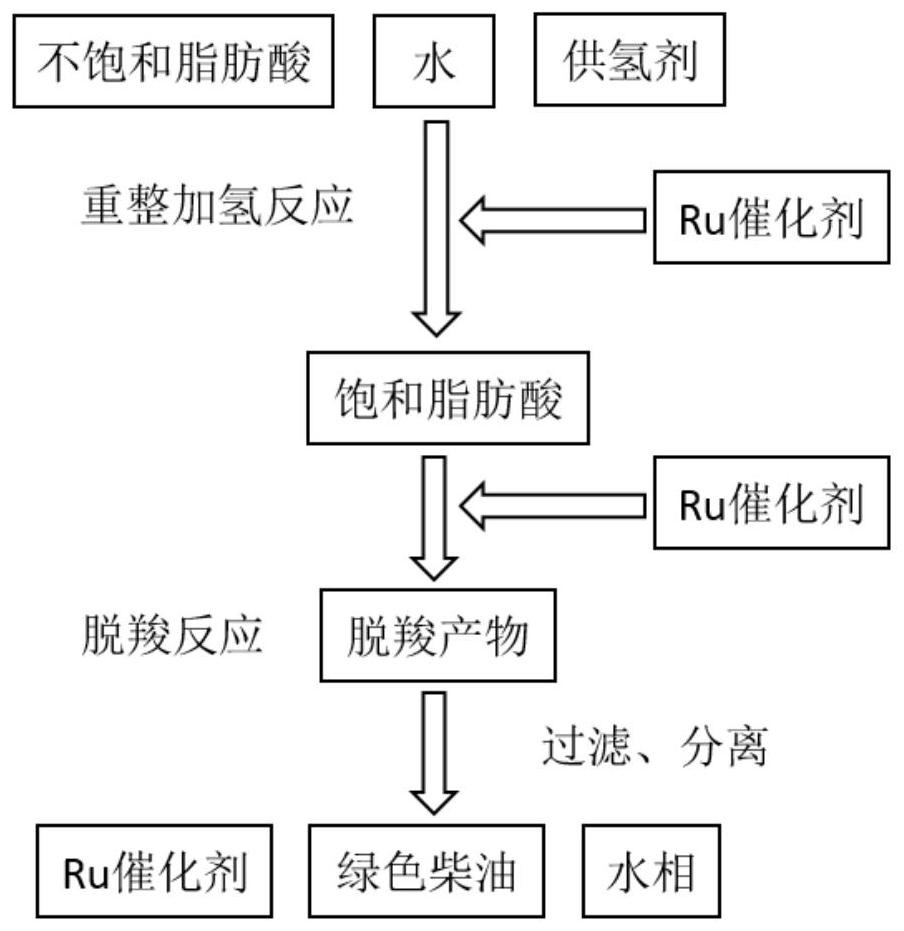

An unsaturated fatty acid and decarboxylation technology, which is applied in the hydrogenation of fatty acids, the preparation of liquid hydrocarbon mixtures, base materials, etc., can solve the problems of hydrogen consumption and slow reaction rate, and achieve the effect of ensuring economy, fast rate and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Add 10g oleic acid, 1g glycerol, 1g 5wt%Ru / C catalyst, 160g H 2 O, and sealed, filled with N into the reactor 2 , keep the initial pressure at 2MPa, and the stirring rate at 500rpm. Heat up to 330°C for 3 hours. After the reaction is finished, the reaction product is cooled to room temperature, dissolved in dichloromethane, and filtered to obtain a liquid phase product and a solid catalyst, and the obtained liquid phase product is separated by standing to obtain oil in the organic phase and water in the inorganic phase. The separated organic phase is analyzed by GC / FID after dichloromethane constant volume, and the conversion rate of oleic acid is 100%, and the yield of long-chain alkane is calculated (the ratio of the amount of long-chain alkane substance and the amount of reactant substance) 89.8%, including C7 0.60%, C8 0.82%, C9 1.26%, C10 1.70%, C11 2.15%, C12 2.66%, C13 3.56%, C14 4.69%, C15 6.89%, C16 10.53%, C17 62.90 %, C18 2.24%.

Embodiment 2

[0049] Add 10g linoleic acid, 0.5g urea, 1g 5wt%Ru / ZrO 2 Catalyst, 100g H 2 O, and sealed, filled with N into the reactor 2 , keep the initial pressure at 2MPa, and the stirring rate at 500rpm. Heat up to 330°C for 4 hours. After the reaction is finished, the reaction product is cooled to room temperature, dissolved in dichloromethane, and filtered to obtain a liquid phase product and a solid catalyst, and the obtained liquid phase product is separated by standing to obtain oil in the organic phase and water in the inorganic phase. The separated organic phase is analyzed by GC / FID after dichloromethane constant volume, and the conversion rate of oleic acid is 96.9%, and the yield of long-chain alkane is calculated (the ratio of the amount of long-chain alkane substance and the amount of reactant substance) 84.7%, including C7 0.31%, C80.56%, C9 0.78%, C10 0.88%, C11 1.84%, C12 1.73%, C13 2.46%, C14 3.62%, C156.07%, C16 10.13%, C17 71.00 %, C18 0.62%.

Embodiment 3

[0051] Add 10g of linolenic acid, 20g of methanol, 0.5g of 5wt%Ru / Al in a 250mL batch type high temperature and high pressure reactor 2 o 3 Catalyst, 80g H 2 O, and seal it, fill Ne into the reactor, keep the initial pressure as 1MPa, and the stirring rate as 500rpm. Heat up to 300°C for 9 hours. After the reaction is finished, the reaction product is cooled to room temperature, dissolved in dichloromethane, and filtered to obtain a liquid phase product and a solid catalyst, and the obtained liquid phase product is separated by standing to obtain oil in the organic phase and water in the inorganic phase. The separated organic phase is analyzed by GC / FID after dichloromethane constant volume, and the conversion rate of oleic acid is 100%, and the yield of long-chain alkane is calculated (the ratio of the amount of long-chain alkane substance and the amount of reactant substance) 91.1%, including C7 3.41%, C8 4.54%, C9 6.05%, C10 8.07%, C11 10.76%, C12 10.82%, C13 10.13%, C14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com