Preparation and application of Fe3O4@C@MoS2 composite material with core-shell structure

A technology of core-shell structure and composite materials, applied in other chemical processes, electrical components, magnetic field/electric field shielding, etc., can solve problems such as interference of electronic equipment, instruments and communication signals, and achieve excellent microwave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

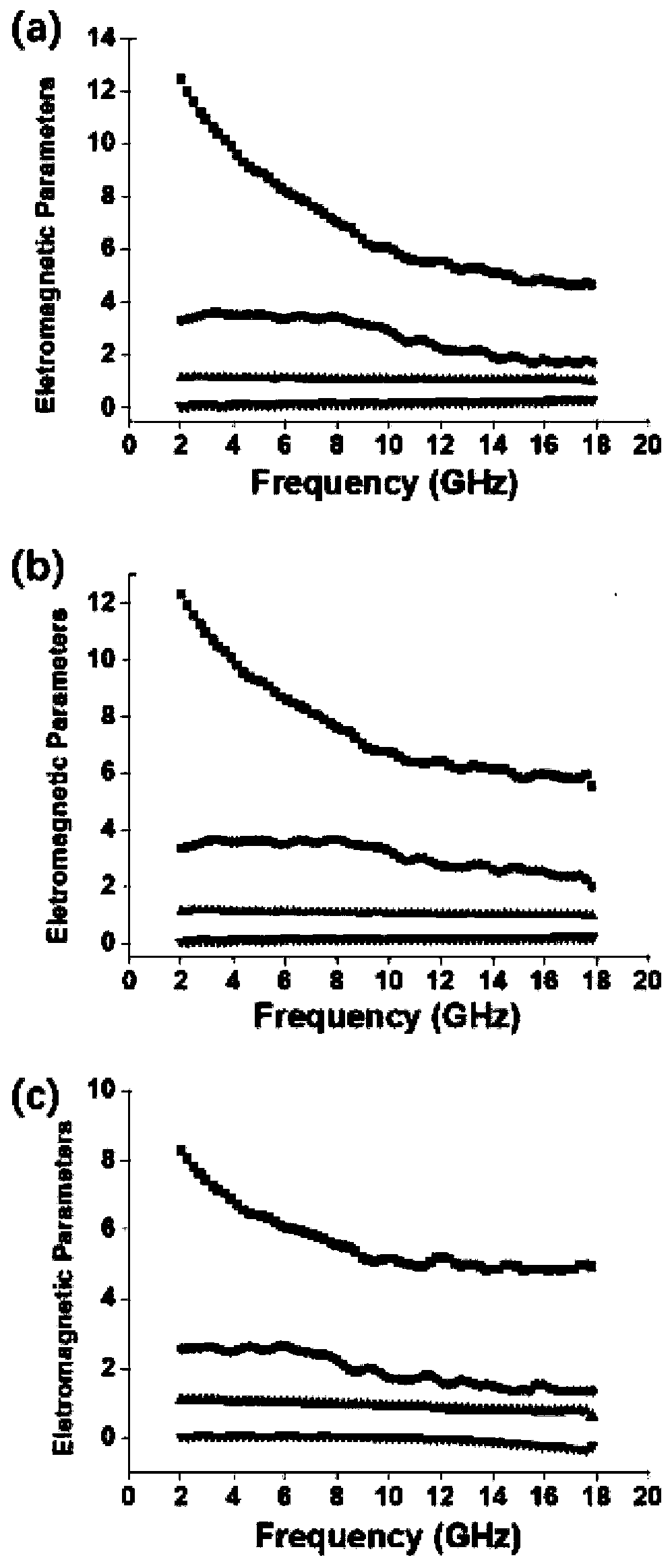

Embodiment 1

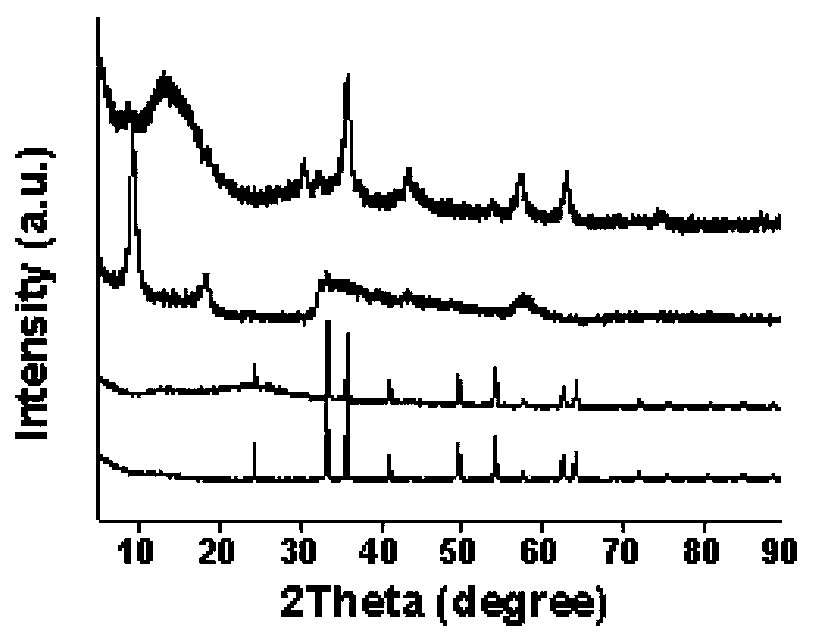

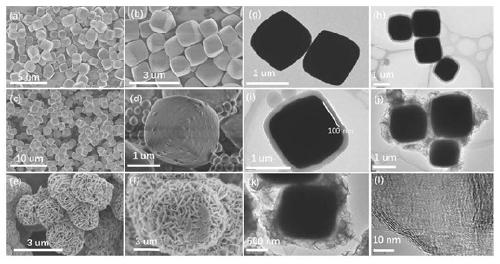

[0024] S1: Fe 2 o 3 Particle preparation: FeCl 3 After adding NaOH and NaOH into water and mixing evenly, the mixed solution is put into a polytetrafluoroethylene stainless steel autoclave to react to obtain a uniform cubic Fe 2 o 3 Particles, of which: FeCl 3 5 parts, 1 part of NaOH, 500 parts of water, the reaction condition is constant temperature reaction at 140°C for 15 hours;

[0025] S2: Fe 2 o 3 Preparation of @PDA complex: the Fe prepared in S1 2 o 3 The particles and dopamine hydrochloride were added to tris buffer solution, stirred and reacted with a magnetic stirrer at room temperature, and then the reaction product was washed, and the core-shell structure Fe was collected by centrifugation. 2 o 3 @PDA complex where Fe 2 o 3 The mass ratio of particles, dopamine hydrochloride and Tris buffer (pH=8.5) is 1:2.4:2.4, the stirring speed of the magnetic stirrer is 500r / min, the stirring time is 12h, and the washing conditions are Wash 3 times with water and ...

Embodiment 2

[0029] S1: Fe 2 o 3 Particle preparation: FeCl 3 After adding NaOH and NaOH into water and mixing evenly, the mixed solution is put into a polytetrafluoroethylene stainless steel autoclave to react to obtain a uniform cubic Fe 2 o 3 Particles, of which: FeCl 3 2 parts, 0.5 parts of NaOH, 400 parts of water, the reaction conditions are constant temperature reaction at 120°C for 12 hours;

[0030] S2: Fe 2 o 3 Preparation of @PDA complex: the Fe prepared in S1 2 o 3 The particles and dopamine hydrochloride were added to tris buffer solution, stirred and reacted with a magnetic stirrer at room temperature, and then the reaction product was washed, and the core-shell structure Fe was collected by centrifugation. 2 o 3 @PDA complex where Fe 2 o 3The mass ratio of particles, dopamine hydrochloride and tris buffer (pH=8.5) is 1:2:2, the stirring speed of the magnetic stirrer is 400r / min, the stirring time is 10h, and the washing conditions are Wash twice with water and et...

Embodiment 3

[0034] S1: Fe 2 o 3 Particle preparation: FeCl 3 After adding NaOH and NaOH into water and mixing evenly, the mixed solution is put into a polytetrafluoroethylene stainless steel autoclave to react to obtain a uniform cubic Fe 2 o 3 Particles, of which: FeCl 3 8 parts, 1.5 parts of NaOH, 600 parts of water, and the reaction conditions are constant temperature reaction at 160°C for 18 hours;

[0035] S2: Fe 2 o 3 Preparation of @PDA complex: the Fe prepared in S1 2 o 3 The particles and dopamine hydrochloride were added to tris buffer solution, stirred and reacted with a magnetic stirrer at room temperature, and then the reaction product was washed, and the core-shell structure Fe was collected by centrifugation. 2 o 3 @PDA complex where Fe 2 o 3 The mass ratio of particles, dopamine hydrochloride and tris buffer (pH=8.5) is 1:3:3, the stirring speed of the magnetic stirrer is 600r / min, the stirring time is 14h, and the washing conditions are Wash 4 times with water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com