Hot melt adhesive tape organic molecular composition

A technology of organic molecules and hot-melt tapes, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problem of affecting the use effect, increasing the difficulty of construction, and easy bonding of colloidal particles, etc. problem, to achieve the effect of reducing construction difficulty and stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

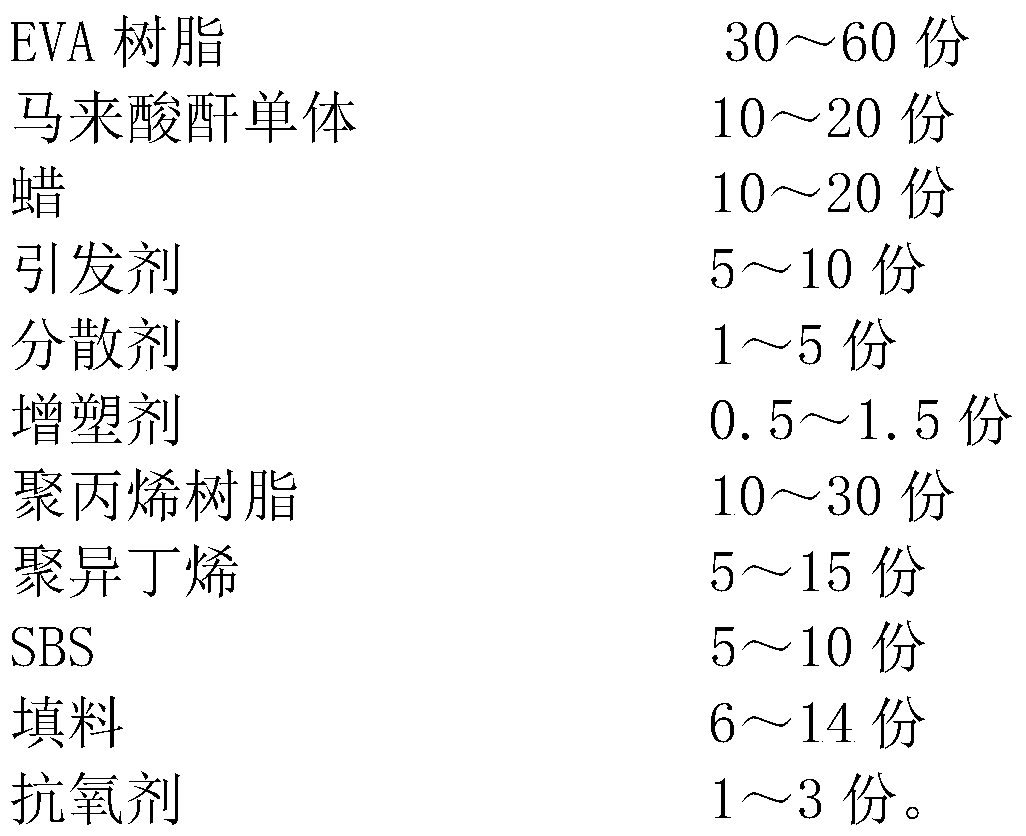

[0019] A hot-melt adhesive tape organic molecular composition, the composition comprising the following parts by weight of raw materials:

[0020]

[0021] EVA resin includes EVA800 and EVA900, and the component ratio of EVA800 and EVA900 is 2:1.

[0022] Wax is microcrystalline wax.

[0023] The initiator is one of benzoyl peroxide and azobisisobutyronitrile.

[0024] The filler is at least one of calcium carbonate, talc, silica powder and color masterbatch.

[0025] A preparation method of an organic molecular composition of a hot melt adhesive tape, the preparation method comprising the following steps:

[0026] S1: Add EVA resin, maleic anhydride monomer, wax, initiator, dispersant, plasticizer, polypropylene resin, polyisobutylene, filler, antioxidant and SBS into the reactor in sequence to melt, mix and stir, the melting temperature is 150 ℃, get a mixture;

[0027] S2: Add the mixture in S1 to the extruder for melt extrusion;

[0028] S3: The rubber strip extruded in S2 is cooled b...

Embodiment 2

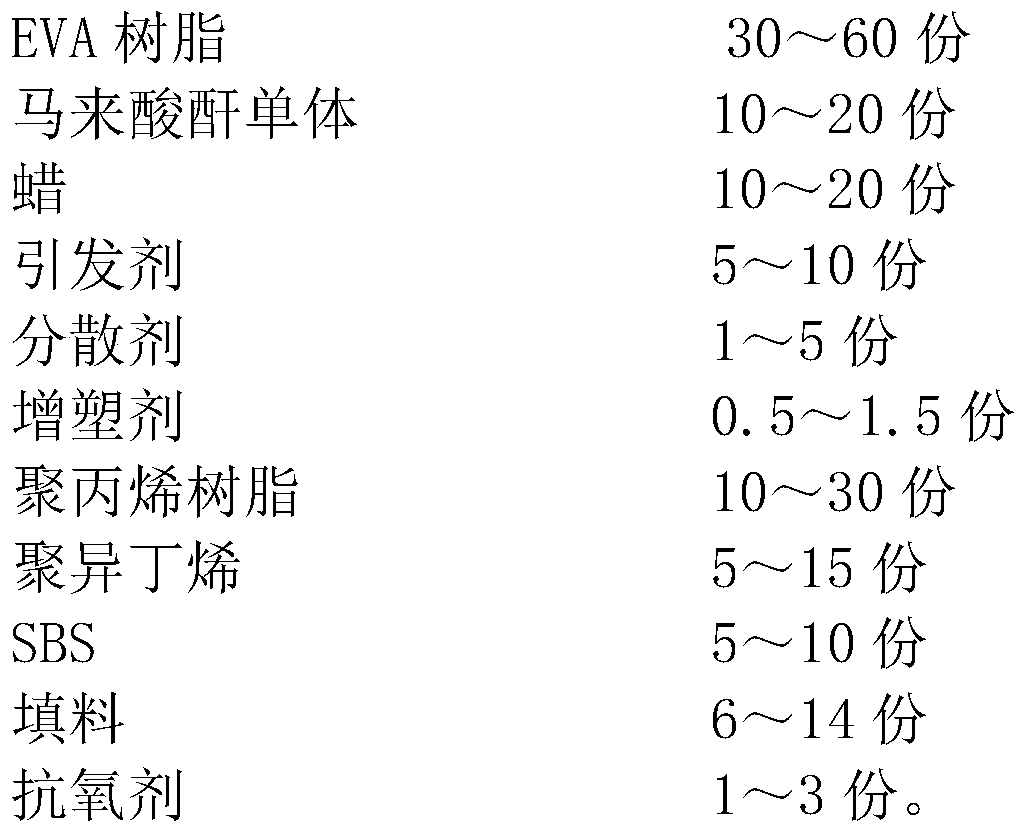

[0031] A hot-melt adhesive tape organic molecular composition, the composition comprising the following parts by weight of raw materials:

[0032]

[0033] EVA resin includes EVA800 and EVA900, and the component ratio of EVA800 and EVA900 is 2:1.

[0034] Wax is microcrystalline wax.

[0035] The initiator is one of benzoyl peroxide and azobisisobutyronitrile.

[0036] The filler is at least one of calcium carbonate, talc, silica powder and color masterbatch.

[0037] A preparation method of an organic molecular composition of a hot melt adhesive tape, the preparation method comprising the following steps:

[0038] S1: Add EVA resin, maleic anhydride monomer, wax, initiator, dispersant, plasticizer, polypropylene resin, polyisobutylene, filler, antioxidant and SBS into the reactor in sequence to melt, mix and stir, the melting temperature is 165 ℃, get a mixture;

[0039] S2: Add the mixture in S1 to the extruder for melt extrusion;

[0040] S3: The rubber strip extruded in S2 is cooled b...

Embodiment 3

[0043] A hot-melt adhesive tape organic molecular composition, the composition comprising the following parts by weight of raw materials:

[0044]

[0045]

[0046] EVA resin includes EVA800 and EVA900, and the component ratio of EVA800 and EVA900 is 2:1.

[0047] Wax is microcrystalline wax.

[0048] The initiator is one of benzoyl peroxide and azobisisobutyronitrile.

[0049] The filler is at least one of calcium carbonate, talc, silica powder and color masterbatch.

[0050] A preparation method of an organic molecular composition of a hot melt adhesive tape, the preparation method comprising the following steps:

[0051] S1: Add EVA resin, maleic anhydride monomer, wax, initiator, dispersant, plasticizer, polypropylene resin, polyisobutylene, filler, antioxidant and SBS into the reactor in order to melt, mix and stir, and the melting temperature is 180 ℃, get a mixture;

[0052] S2: Add the mixture in S1 to the extruder for melt extrusion;

[0053] S3: The rubber strip extruded in S2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com