Wear-resistant and oil-resistant engineering sole material and preparation method thereof

A shoe sole material and engineering technology, which is applied in the field of elastomer engineering sole material and its preparation, can solve the problems of difficult dispersion of fillers and auxiliaries, and achieve the effects of solving poor dispersion, reducing wear volume and increasing cross-linking points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

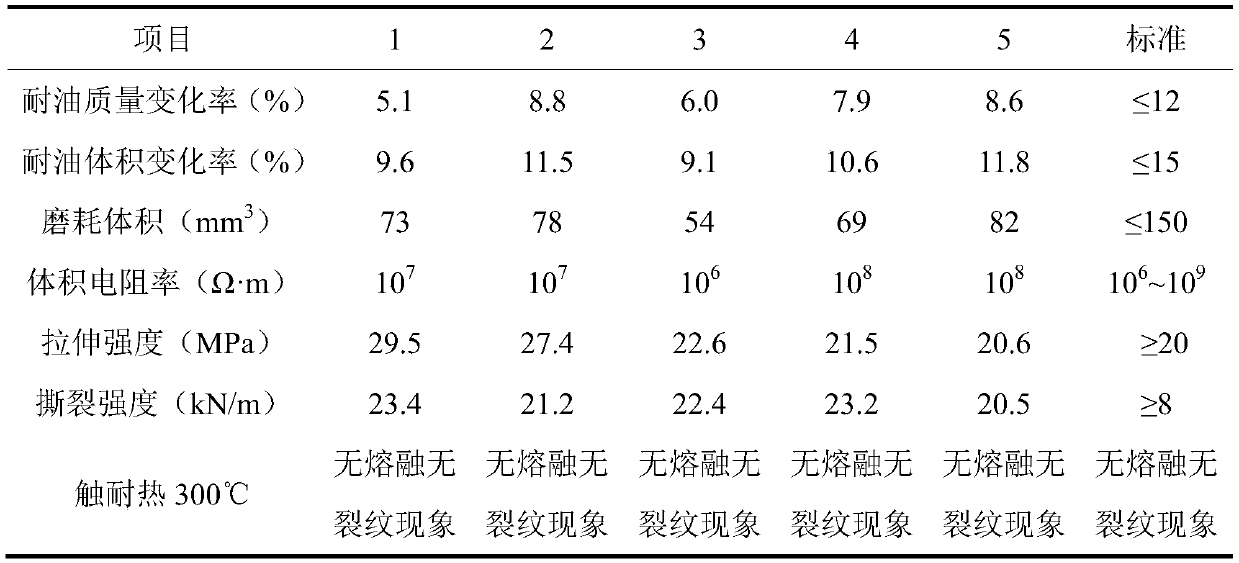

Examples

Embodiment 1

[0056] A wear-resistant and oil-resistant engineering shoe sole material, the raw materials of which are composed of:

[0057] EVA 4260: 40 parts

[0058] Nitrile rubber NBR (acrylonitrile content 33%): 60 parts

[0059] nano-SiO 2 : 5 servings

[0060] Carbon black N110: 20 parts

[0061] Si-69: 5 parts

[0062] BIPB: 1.5 copies

[0064] Stearic acid: 0.8 parts

[0065] Zinc stearate: 2.5 parts

[0066] N4016 naphthenic oil: 4 parts

[0067] Antiaging agent RD: 0.5 parts

[0068] A preparation method of a wear-resistant and oil-resistant engineering shoe sole material is as follows:

[0069] Add 40 parts of EVA into the internal mixer, press the top bolt, control the temperature at 80°C, rotate at a speed of 50r / min, and banbury for 50s; then add 0.8 parts of zinc oxide, 0.32 parts of stearic acid, and 1 part of zinc stearate in sequence , Si-69 2 parts, nano-SiO 2 2 parts, 8 parts of carbon black N110, 1.6 parts of N4016 naphthenic o...

Embodiment 2

[0073] A wear-resistant and oil-resistant engineering shoe sole material, the raw materials of which are composed of:

[0074] EVA 4260: 70 parts

[0075] Neoprene CR: 30 parts

[0076] nano-SiO 2 : 10 servings

[0077] Carbon black N110: 40 parts

[0078] Si-69: 15 parts

[0079] BIPB: 3 copies

[0080] Zinc oxide: 5 parts

[0081] Stearic acid: 2 parts

[0082] Zinc stearate: 1 part

[0083] N4016 naphthenic oil: 10 parts

[0084] Antiager AW: 2 parts

[0085] A preparation method of a wear-resistant and oil-resistant engineering shoe sole material is as follows:

[0086] Add 70 parts of EVA into the internal mixer, press the top bolt, control the temperature at 80°C, rotate at a speed of 50r / min, and banbury for 50s; then add 3.5 parts of zinc oxide, 1.4 parts of stearic acid, and 0.7 parts of zinc stearate in sequence , Si-69 10.5 parts, nano-SiO 2 7 parts, 28 parts of N110, 7 parts of N4016 naphthenic oil, 1.4 parts of anti-aging agent RD and 2.1 parts of BIP...

Embodiment 3

[0090] A wear-resistant and oil-resistant engineering shoe sole material, the raw materials of which are composed of:

[0091] EVM 500HV: 50 parts

[0092] Nitrile rubber NBR (acrylonitrile content 42%): 50 parts

[0093] Nano-CaCO 3 : 5 servings

[0094] Carbon black N110: 30 parts

[0095] KH550: 10 parts

[0096] DCP: 2.5 copies

[0097] Zinc oxide: 2.5 parts

[0098] Stearic acid: 1.5 parts

[0099] Zinc stearate: 2 parts

[0100] N4016 naphthenic oil: 8 parts

[0101] Antiager 4020: 1.5 parts

[0102] A preparation method of a wear-resistant and oil-resistant engineering shoe sole material is as follows:

[0103] Add 50 parts of EVM into the internal mixer, press the top bolt, control the temperature at 80°C, rotate at a speed of 55r / min, and banbury for 60s; then add 1.25 parts of zinc oxide, 0.75 parts of stearic acid, and 1 part of zinc stearate in sequence , KH550 5 parts, nano CaCO 3 2.5 parts, 15 parts of N11015, 4 parts of N4016 naphthenic oil, 0.75 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com