Thermally-induced liquid crystal polymer and preparation method and application thereof

A thermotropic liquid crystal and polymer technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problem of high price, achieve the effects of easy acquisition, improved melt tension, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An embodiment of the preparation method of the thermotropic liquid crystal polymer of the present invention, the preparation method of the thermotropic liquid crystal polymer comprises the following steps:

[0048] S1. Add 6.12kg of raw materials 4-hydroxybenzoic acid (HBA), 2.75kg of biphenol (BP), 7.87kg of acetic anhydride (AA) and 1g of magnesium acetate into the first reactor, and completely replace the reaction vessel with nitrogen Under the protection of nitrogen, the temperature of the reaction system was raised to 140 ° C, and the temperature was maintained at reflux for 2 hours to carry out the acetylation reaction;

[0049] S2. After the acetylation reaction is finished, the material is transferred to the second reactor equipped with a stirrer with a torque sensor, and 1.84kg of phthalic acid (TA) and 0.61kg of isophthalic acid (IA) are put into the second reactor. , then stir, and raise the temperature to 340°C (T1) at a heating rate of 1°C / min, and then rai...

Embodiment 2

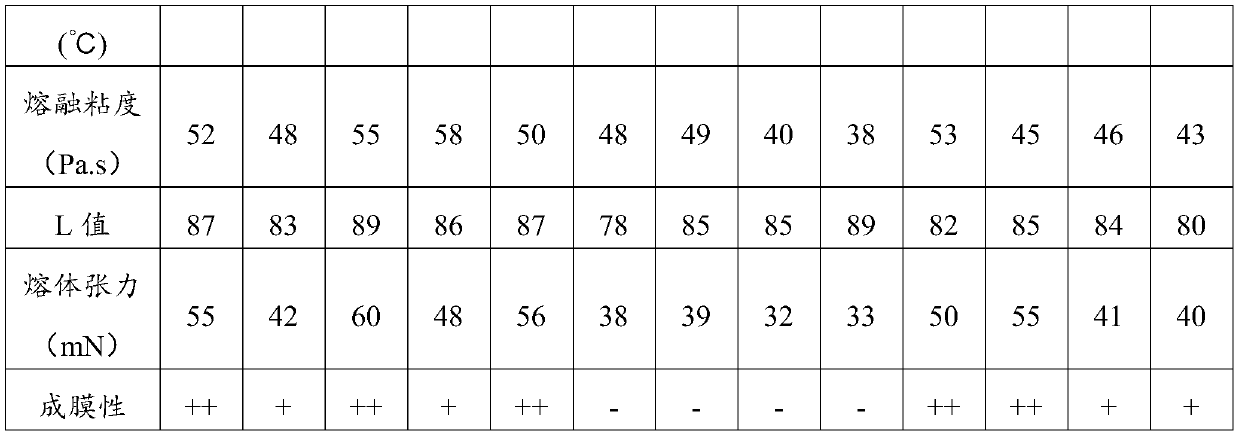

[0051] The difference between the preparation method of the thermotropic liquid crystal polymer described in Example 2 and Example 1 lies in the temperature rise rate in S2, see Table 1.

Embodiment 3

[0060] An embodiment of the preparation method of the thermotropic liquid crystal polymer of the present invention, the preparation method of the thermotropic liquid crystal polymer comprises the following steps:

[0061] S1. Add 7.55kg of raw materials 4-hydroxybenzoic acid (HBA), 3.80kg of 6-hydroxy-2-naphthoic acid (HNA), 7.82kg of acetic anhydride (AA) and 1g of magnesium acetate into the first reactor. Replace the atmosphere in the reaction vessel, raise the temperature of the reaction system to 140°C under the protection of nitrogen, and maintain the temperature at reflux for 2 hours to carry out the acetylation reaction;

[0062] S2. After the acetylation reaction is completed, transfer the material to the second reactor equipped with a stirrer with a torque sensor, then raise the temperature to 270°C (T1) at a heating rate of 1°C / min, and then increase the temperature at a rate of 0.4°C / min The heating rate is raised to 310°C (T2), and the generated acetic acid is disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com