A kind of bio-adhesive binder based on waterborne polyurethane modification and preparation method thereof

A technology of water-based polyurethane and bio-glue, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of difficult popularization and application, harsh casting conditions, and difficult regeneration of molding sand, etc., and achieve broad market prospects and good collapsibility , the effect of no obvious decrease in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

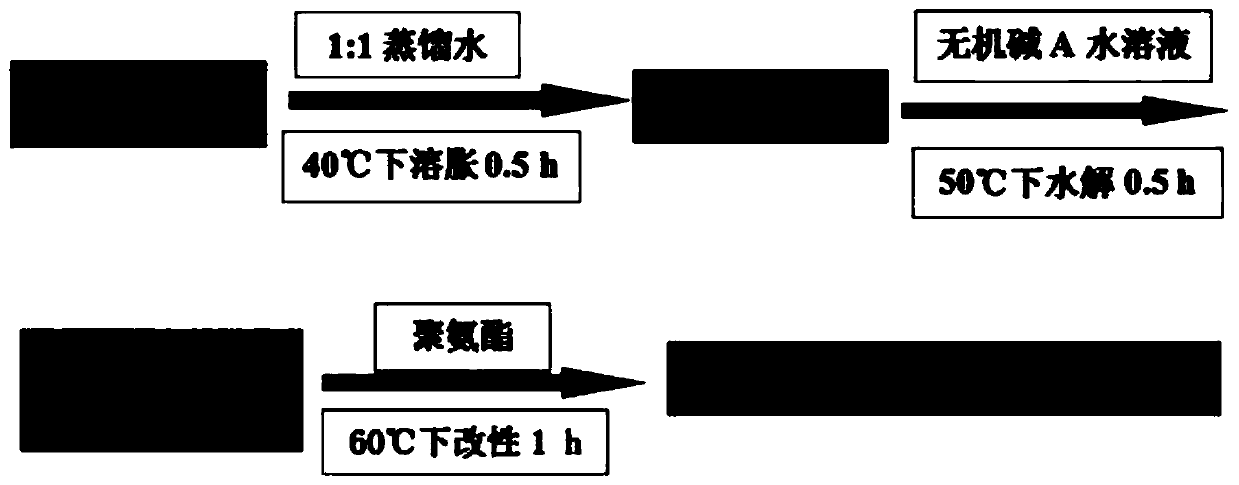

[0025] like figure 1 As shown, the preparation method based on the water-based polyurethane modified bio-adhesive binder provided by the embodiments of the present invention may further comprise the steps:

[0026] In the first step, weigh 50g of biogel solid particles and transfer them to a 250mL three-necked bottle, add 45mL of distilled water to swell, and after the water is swollen, place it on the electric heating mantle with a pre-set temperature of 70°C and set up a mechanical stirring device. Turn on the stirring; the rotating speed is 120r / min. When heating until the temperature of the bioglue is 40°C, keep the temperature constant, and react for 0.5h.

[0027] In the second step, after heating at 40°C for 0.5h, the bioglue is completely dissolved. Increase the rotation speed to 200r / min, raise the temperature to 50°C, add an aqueous solution of inorganic base A (2g of inorganic base A is dissolved in 5mL of distilled water), and react for 0.5 h. As the reaction pr...

example 1

[0031] Example 1 is based on water-based polyurethane modified bio-adhesive binder, made of the following raw material components,

[0032] The sand particle size is 1Kg of quartz sand of 50-100 mesh, 0.05Kg of bio-glue particles, 0.05Kg of tap water, and 0.001Kg of modifier.

[0033] The preparation method of the "8" block type sand sample based on biological glue binder comprises the following steps:

[0034] Step 1: transfer the accurately weighed quartz sand into the sand mixer and start stirring;

[0035] Step 2 Slowly add inorganic base B (8g) into the sand mixer, and mix evenly at a certain speed for 15s.

[0036] Step 3 Slowly add 40g of bio-glue binder and stir for 60s-90s.

[0037] Step 4 Put an appropriate amount of evenly mixed quartz sand into the cold box testing machine, set the air blowing time to 5 minutes, and the air blowing pressure to 0.4MPa~0.8MPa.

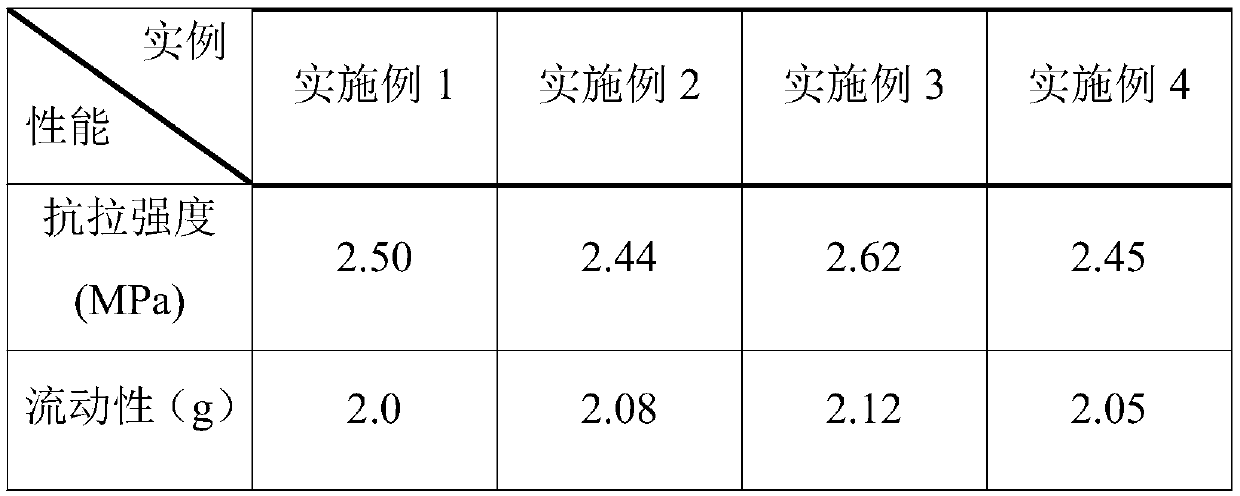

[0038] Step 5 Take out the sand sample from the cold box testing machine and test its corresponding mec...

example 2

[0039] Example 2 is based on the bio-adhesive binder modified by water-based polyurethane, made of the following raw material components:

[0040] The sand particle size is 1Kg of quartz sand of 50-100 mesh, 0.05Kg of bio-glue particles, 0.05Kg of tap water, and 0.001Kg of modifier.

[0041] The preparation method of the "8" block type sand sample based on biological glue binder comprises the following steps:

[0042] Step 1: Transfer the accurately weighed quartz sand into the sand mixer and start stirring.

[0043] Step 2 Slowly add inorganic base B (8g) into the sand mixer, and mix evenly at a certain speed for 15s.

[0044] Step 3 Slowly add 40g of bio-glue binder and stir for 90s-120s.

[0045] Step 4 Put an appropriate amount of quartz sand mixed evenly into the cold box testing machine, set the air blowing time to 5 minutes, and the air blowing pressure to 0.4MPa-0.8MPa.

[0046] Step 5 Take out the sand sample from the cold box testing machine and test its correspon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com