Single-tower desulfurization white removal device

A technology in the whitening and desulfurization section, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high investment costs, waste of energy and water resources, and colored plumes with only investment but no income, etc., to achieve good results. Social and economic impacts, water conservation, and operating cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

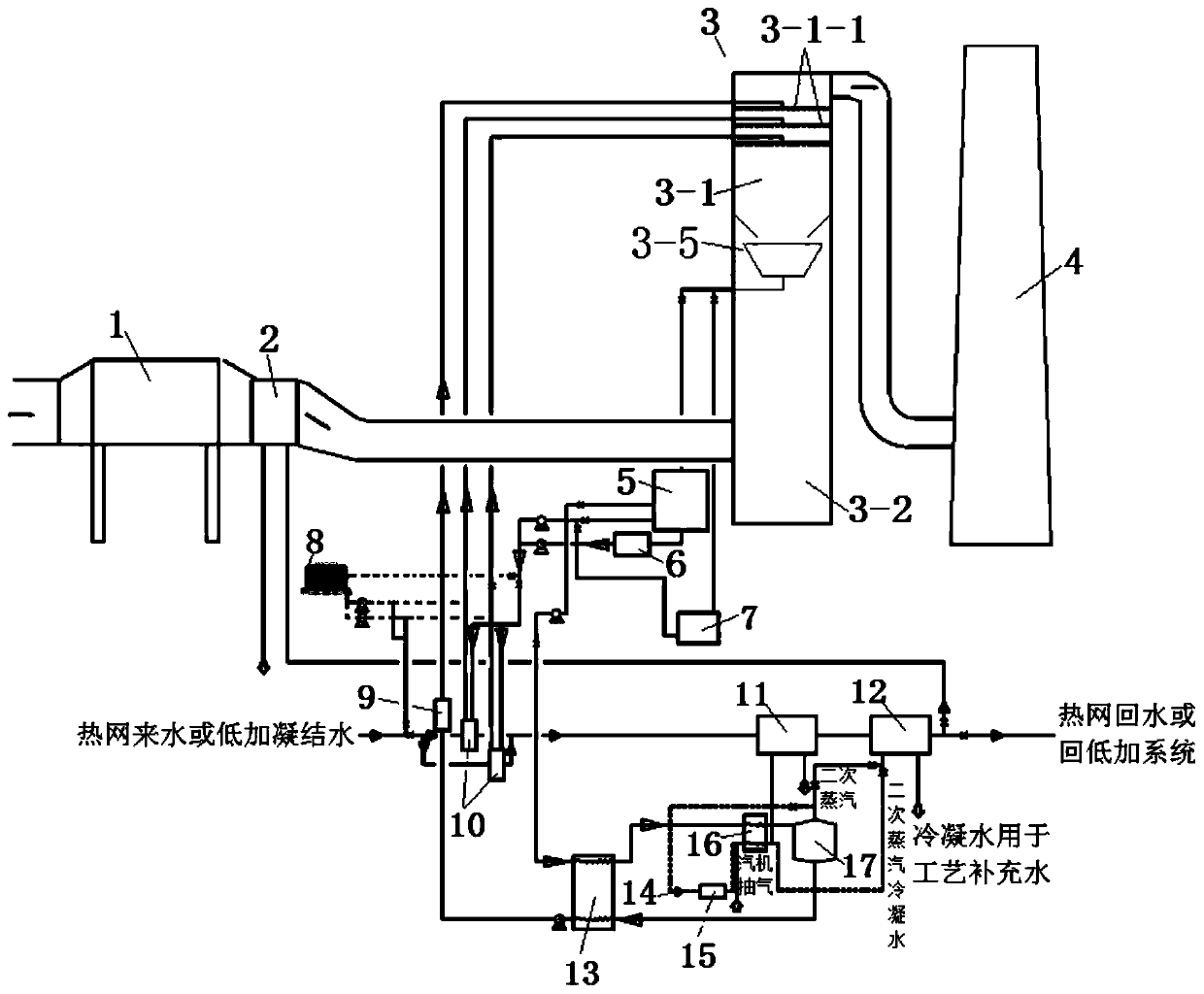

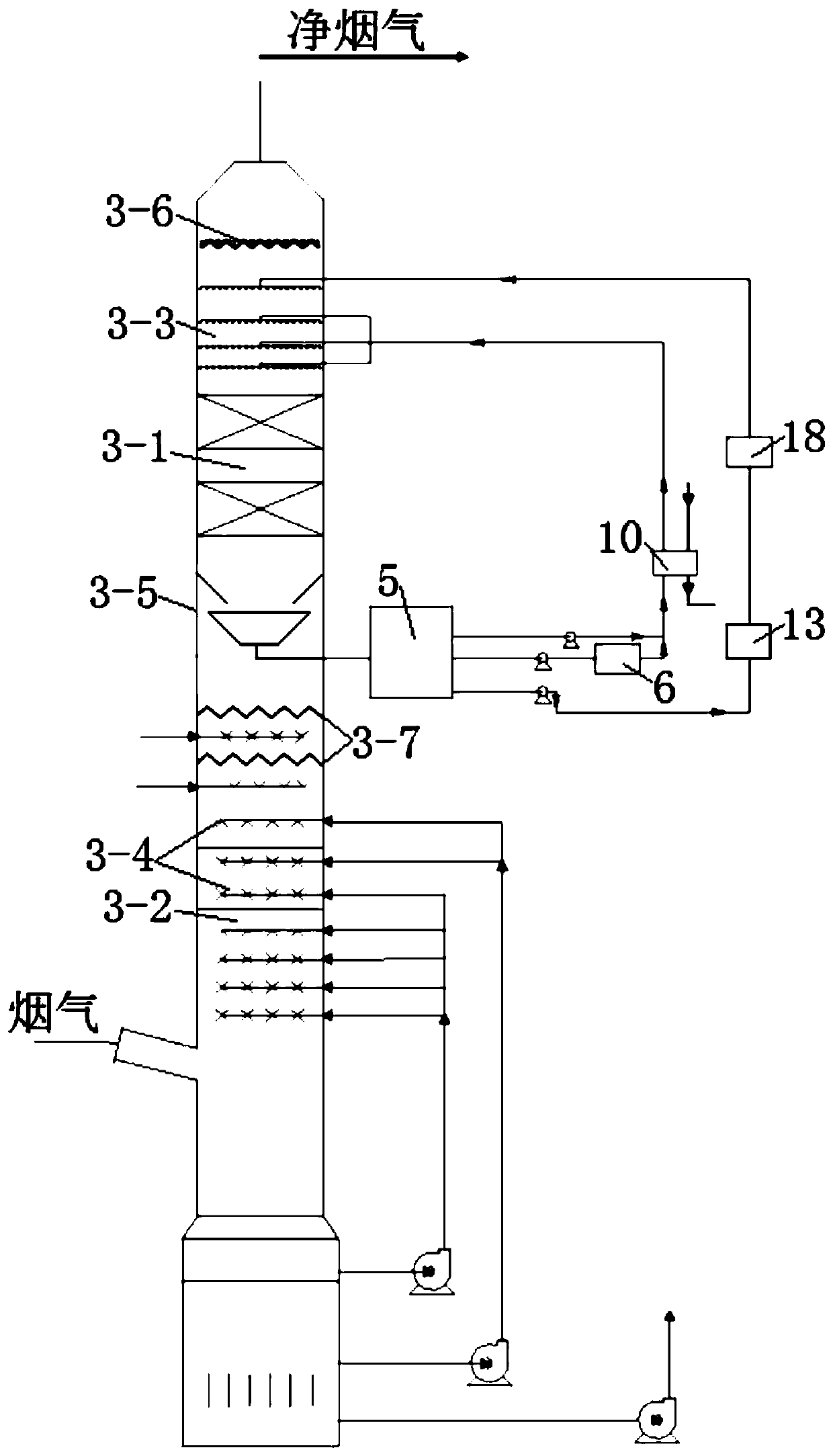

[0047] This embodiment provides a single-tower desulfurization and whitening device, such as figure 1 and 2 As shown, it includes a dust removal device 1, an economizer 2 and a flue gas purification device 3 connected in sequence. For example, the dust removal device 1 can be an electric dust collector, and the flue gas purification device 3 includes a housing, and also includes,

[0048] The desulfurization section 3-2 and the absorption section 3-1 are sequentially arranged in the shell from bottom to top; the absorption section 3-1 can be an empty tower section or a packed tower section, and when it is a packed tower section, the packing can be a single layer or multiple layers; the top of the absorption section 3-1 is provided with a net flue gas outlet;

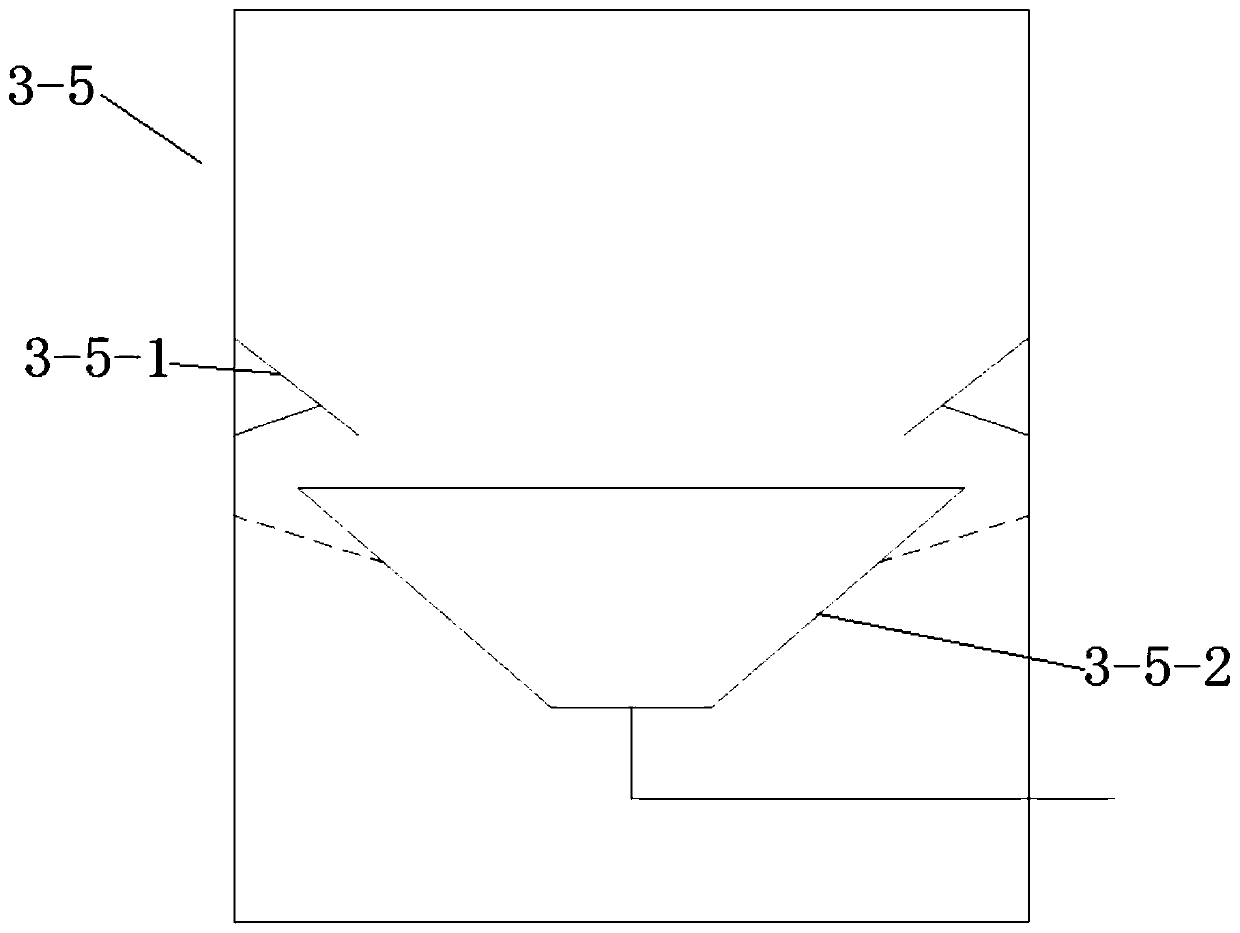

[0049] The liquid storage unit 3-5 is arranged between the desulfurization section 3-2 and the absorption section 3-1, and is located in the casing to divide the desulfurization section 3-2 and the absorption section 3-...

Embodiment 2

[0061] This embodiment provides a single-tower desulfurization and whitening device. On the basis of the above-mentioned embodiment 1, it also includes a fifth circulation loop, whose liquid inlet is connected with the liquid storage unit 3-5, and the liquid outlet is connected with the first The spray layer 3-3 is connected, and the fifth circulation circuit is provided with a water storage device 7 and a refrigeration device 8, so that in the non-heating season, the water in the water storage device 7 is sent to the refrigeration device 8 for cooling, and then sent to the second A spray layer 3-3 is used to circulate and spray flue gas; in the heating season, the water in the liquid storage unit 3-5 is stored in the water storage device 7; in this embodiment, the refrigeration device 8 is a cooling tower or Closed mechanical ventilation cooling tower; water storage device 7 is a clean water tank;

[0062] In the non-heating season, the absorption section can also use clean w...

Embodiment 3

[0065] This embodiment provides a single-tower desulfurization and whitening device, on the basis of the above-mentioned embodiment 1 or 2, it also includes a second heat exchanger 11 and a third heat exchanger 12, the first heat exchanger 10, the second heat exchanger The second heat exchanger 11 and the third heat exchanger 12 are communicated in sequence, so that the incoming water from the heating network or the condensed water of low-temperature heating passes through the first heat exchanger 10, the second heat exchanger 11 and the third heat exchanger 12 in sequence, and Exchange heat with substances entering the corresponding heat exchanger;

[0066] The fifth heat exchanger 16 communicates with the second heat exchanger 11 and / or the third heat exchanger 12, so as to send the extraction condensed water of the fifth heat exchanger 16 into the second heat exchanger 11 and / or the third heat exchanger 11. After the heat exchange in the heat exchanger 12, it is returned to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com