Clean treatment technology for shale gas oil-based ash residues

A clean treatment, shale gas technology, applied in the direction of culture medium, planting substrate, gardening, etc., can solve the problems of equipment corrosion, non-degradable pollutants, large equipment investment, etc., to achieve good utilization, reduce environmental risks, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

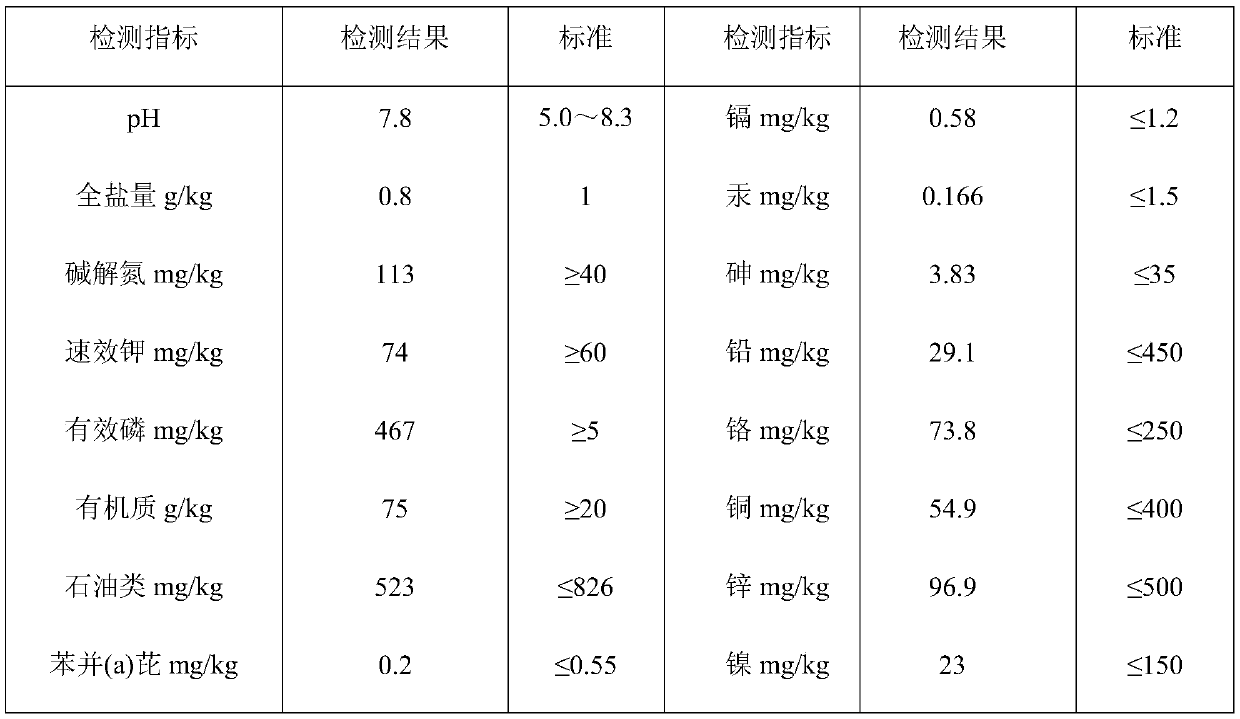

[0023] Shale gas oil-based ash cleaning technology is to mix shale gas oil-based ash and sludge fermentation product in a mass ratio of 1:0.1 (or 1:0.2 or 1:0.3), and then place Irrigate and soak in the salt pond for 24 hours and start draining. After no water flows out, sample and measure the salt content of the mixture. If the salt content is less than 2g / kg, the soaking desalination is over. If the salt content is greater than or equal to 2g / kg, continue the above soaking desalination. process. The desalination pool is constructed of brick walls and plastered inside and outside. The height difference between the two ends of the pool bottom is about 15cm (or 22cm or 30cm), which is conducive to the discharge of water in the pool. The bottom of the pool is constructed of C30 concrete, and the anti-seepage coefficient is less than 1.0 ×10- 7 cm / s. Add 2% oil-based ash slag mass microbial agent to the desalted mixture and mix evenly, stack in strips, turn the pile every 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com