Dry recovery process for waste maintenance-free storage battery

A maintenance-free battery technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of waste battery consumption, environmental secondary pollution, high processing costs, etc., achieve less resource consumption and avoid secondary pollution , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

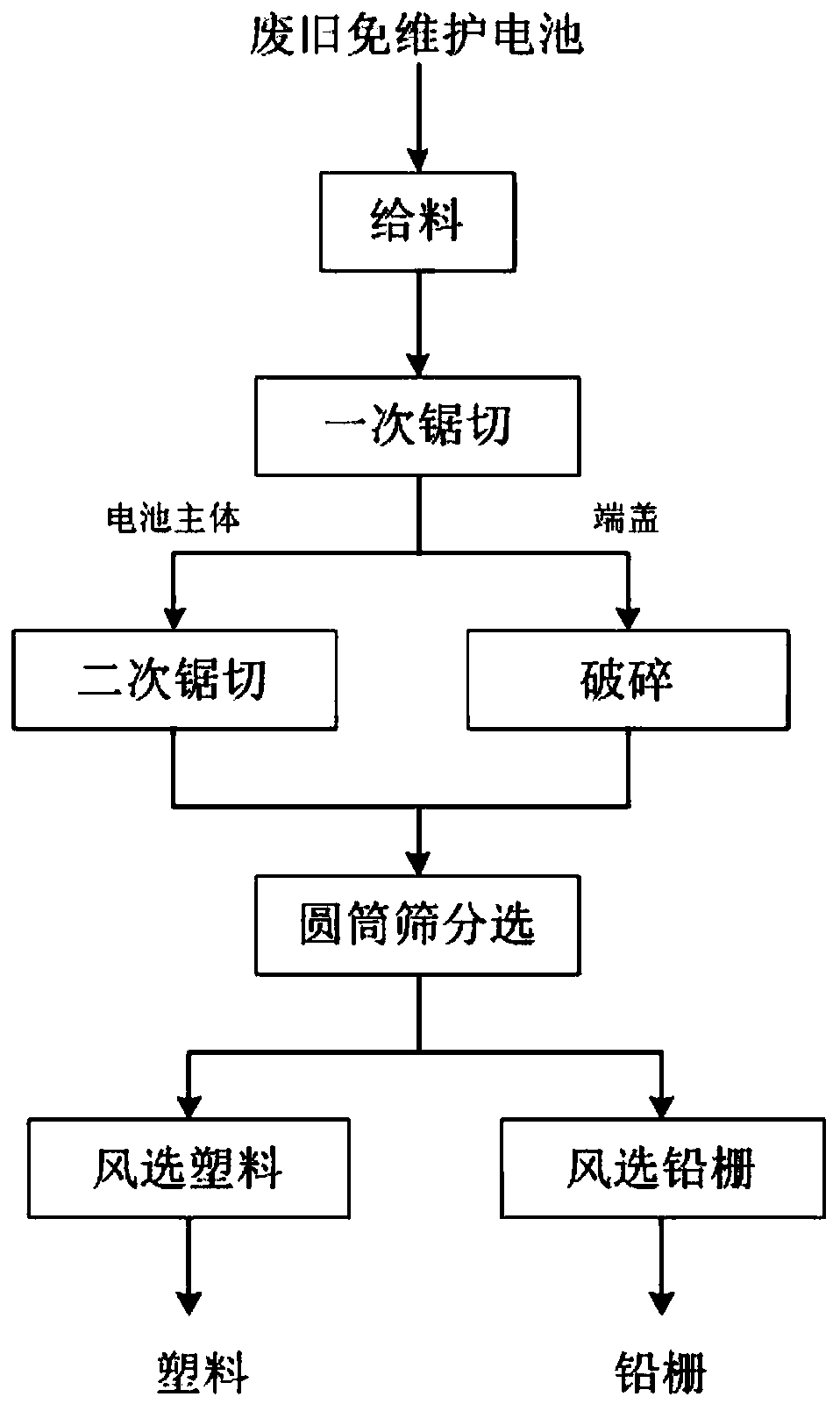

[0052] A dry recovery process for waste maintenance-free storage batteries, the process includes the following steps:

[0053] (1) Feeding: collect waste maintenance-free batteries and place them in storage bins;

[0054] (2) One-time sawing: transport the waste maintenance-free batteries in the silo to the primary sawing device at a delivery rate of (14-15) t / h for sawing, and the sawing is completed to obtain the battery body and battery cover;

[0055] (3) Multiple sawing: The battery body (13-15) t / h obtained in step (2) is transported to the secondary sawing device to perform secondary sawing on the battery body at the same time, and the sawing becomes a three-segment battery body Scrap;

[0056] (4) crushing the battery cover obtained in step (2) in a hammer crusher to obtain mixed scraps of plastics and battery poles;

[0057] Among them, the grate hole of the crusher is 150×50mm; the power of the crusher is (180-200) kW.

[0058] (5) Mix the scraps of the battery ma...

Embodiment 2

[0081] Embodiment 2 and embodiment 1 similarity no longer repeat, and difference is specifically as follows:

[0082] A dry recovery process for waste maintenance-free storage batteries, the process includes the following steps:

[0083] (1) Feeding: collect waste maintenance-free batteries and place them in storage bins;

[0084](2) One-time sawing: transport the waste maintenance-free batteries in the silo to the primary sawing device at a delivery rate of (15-16) t / h for sawing, and the battery body and battery cover are obtained after sawing;

[0085] (3) Multiple sawing: transport the battery body (14-16) t / h obtained in step (2) to the secondary sawing device to perform secondary sawing on the battery body at the same time, and saw to become a three-segment battery body Scrap;

[0086] (4) crushing the battery cover obtained in step (2) in a hammer crusher to obtain mixed scraps of plastics and battery poles;

[0087] Among them, the grate hole of the crusher is 150×5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com