Method for testing hydrogen sulfide stress corrosion resistance of oil well pipe

A technology of stress corrosion and hydrogen sulfide resistance, applied in the direction of testing the strength of materials, measuring devices, instruments, etc. by applying a stable bending force, it can solve the problems of harsh test conditions, high quality requirements for operators, complex model design and theoretical calculations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

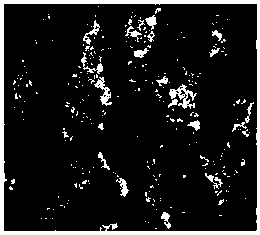

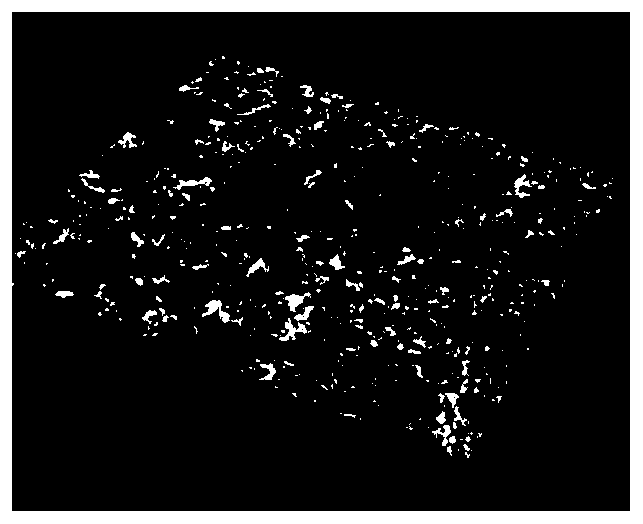

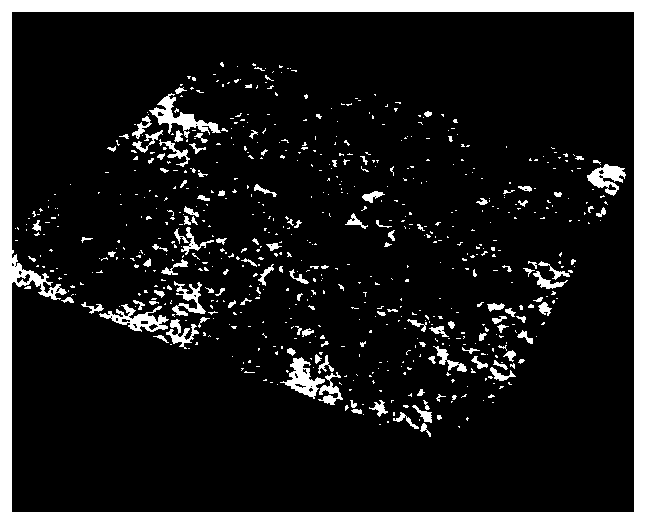

Image

Examples

Embodiment 1

[0022] The samples used in the test are three kinds of oil well pipes A, B, and C, and the three kinds of oil well pipes are three different oil well pipes (for example: oil well pipes with different materials or different processes such as rolling and heat treatment, the following implementation Same explanation here). Three parallel samples of each oil well pipe, the test method consists of a sample processing, b surface treatment, c bending loading test and d sample surface morphology observation and calculation of corrosion pit depth.

[0023] In step a, the sample is processed into a size of 115mm*15mm*5mm, and the surface finish is 0.3μm;

[0024] In step b, the surface treatment test was washed twice with acetone, and then once with absolute ethanol to remove the residue and grease on the surface of the sample;

[0025] In the step c, the bending loading test adopts the four-point bending loading method, and the loading is carried out according to 50% of the nominal yi...

Embodiment 2

[0030] The samples used in the test are oil well pipes A, B, and C, and three parallel samples of each oil well pipe. The test method consists of a sample processing, b surface treatment, c bending loading test and d sample surface morphology Composed of observation and calculation of corrosion pit depth.

[0031] In step a, the sample is processed into a size of 115mm*15mm*5mm, and the surface finish is 0.3μm;

[0032] In step b, the surface treatment test was washed twice with acetone, and then once with absolute ethanol to remove the residue and grease on the surface of the sample;

[0033] In the step c, the bending loading test adopts the four-point bending loading method, and the loading is carried out according to 90% of the nominal yield strength of the oil well pipe. It is the actual well fluid in the oil field, and the test period is 720h without breaking. After the test, the surface rust layer is treated according to the standard GB / T-19292.4, the method of removin...

Embodiment 3

[0038] The samples used in the test are oil well pipes A, B, and C, and three parallel samples of each oil well pipe. The test method consists of a sample processing, b surface treatment, c bending loading test and d sample surface morphology Composed of observation and calculation of corrosion pit depth.

[0039] In step a, the sample is processed into a size of 115mm*15mm*5mm, and the surface finish is 0.3μm;

[0040] In step b, the surface treatment test was washed twice with acetone, and then once with absolute ethanol to remove the residue and grease on the surface of the sample;

[0041] In step c, the bending loading test adopts the four-point bending loading method, and the loading is carried out according to 80% of the nominal yield strength of the oil well pipe. It is a saturated hydrogen sulfide A solution (nace standard), and the test period is 720h without breaking. After the test, the surface rust layer is treated according to the standard GB / T-19292.4, the meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com