One-key kiln baking method and system used for continuous type kiln

An oven method and oven technology, which are applied in the one-key oven method and system field of continuous kilns, can solve the problems of automatic oven program dependence, instability and inaccuracy, etc., to simplify the program setting process and avoid Mistakes, good effect of oven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

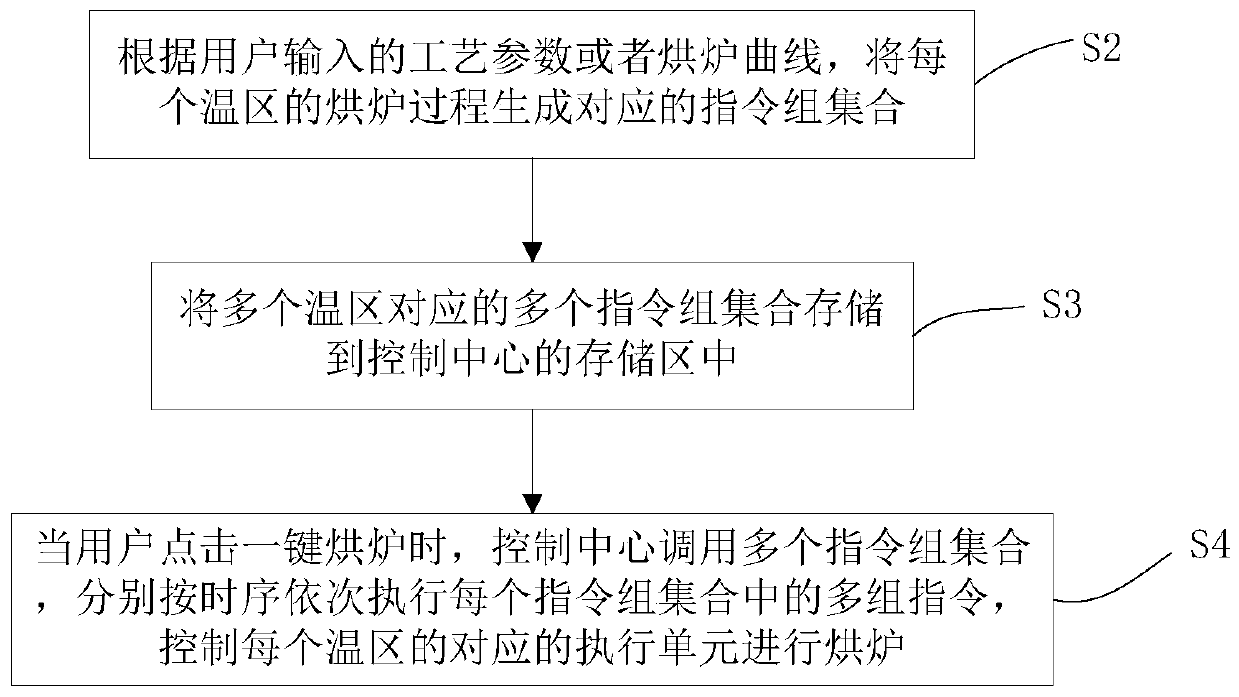

[0045] The one-key oven method for continuous kilns of this embodiment includes the following steps after dividing the continuous kiln into multiple temperature zones (the order of the following steps is not certain, and can be adjusted according to actual conditions) :

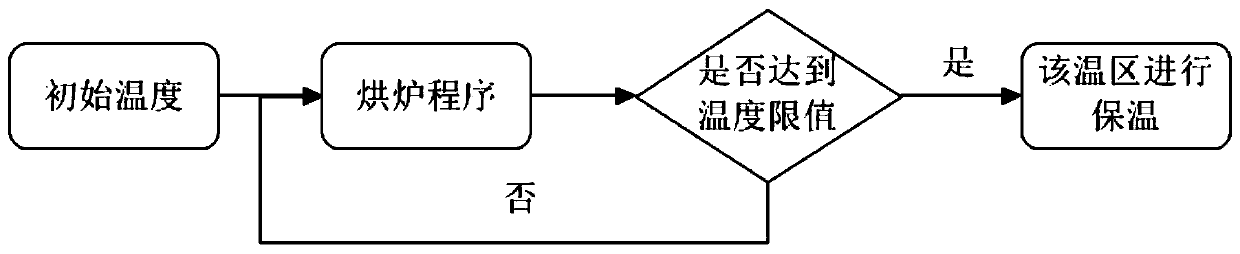

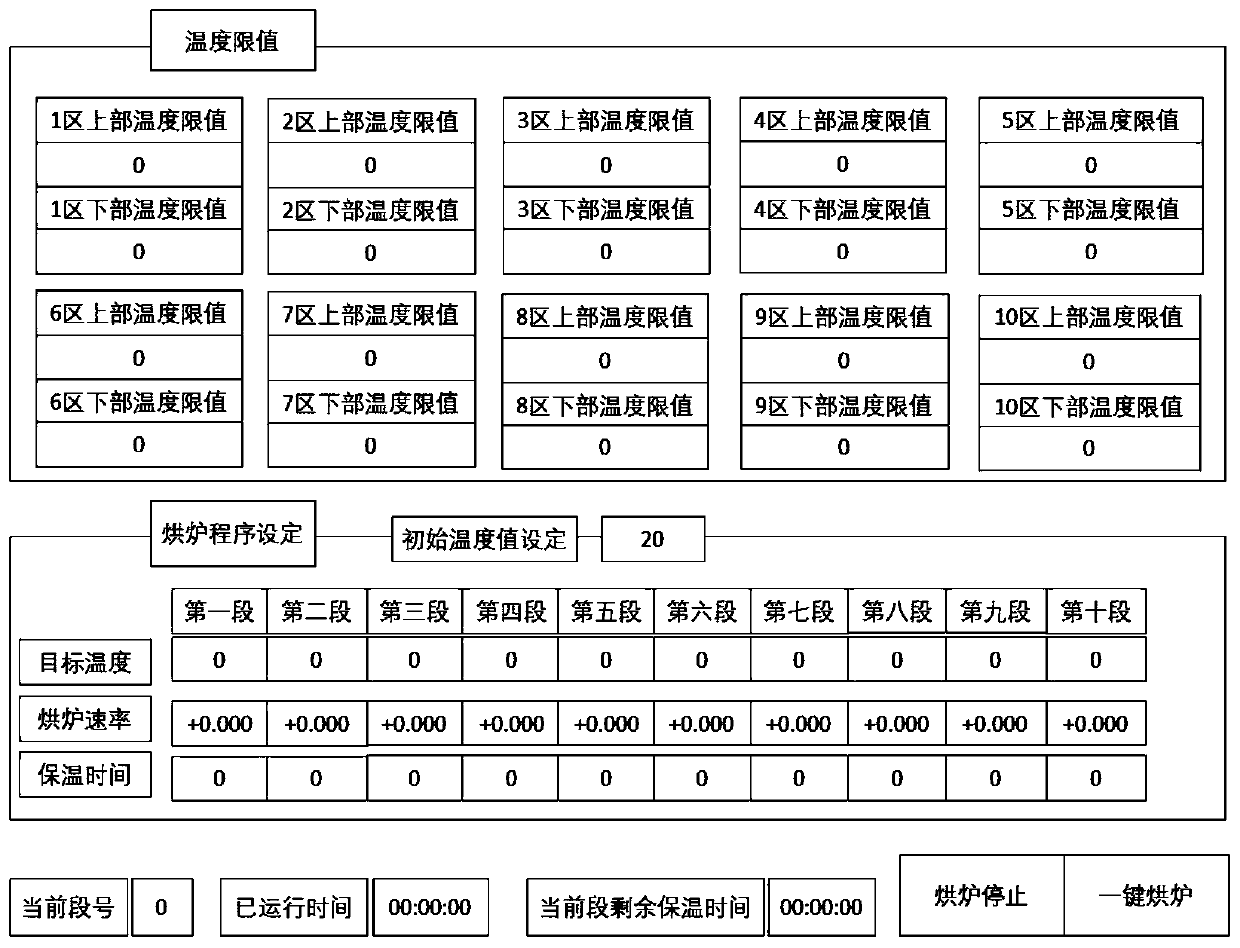

[0046] S1: Obtain the process parameters (including target temperature, oven speed and holding time) or oven curve input by the user, and the maximum temperature of each temperature zone in the entire oven process set by the user (see image 3 , image 3 It is only an example of the input form, where the number 0 does not represent the value entered). During implementation, the maximum temperature of each temperature zone can be set separately for the upper part maximum temperature and the lower part maximum temperature. The upper part maximum temperature and the lower part maximum temperature of each temperature zone can be set separately according to the sintering process temperature of the corresponding prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com