Corner water stop steel plate equipped with fixing device and construction method

A technology of water-stop steel plate and fixing device, applied in water conservancy projects, protection devices, artificial islands, etc., can solve the problems of difficult to control cutting accuracy, hidden leakage, easy loosening, etc., to improve welding work efficiency, improve welding quality, Guaranteed water-stopping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

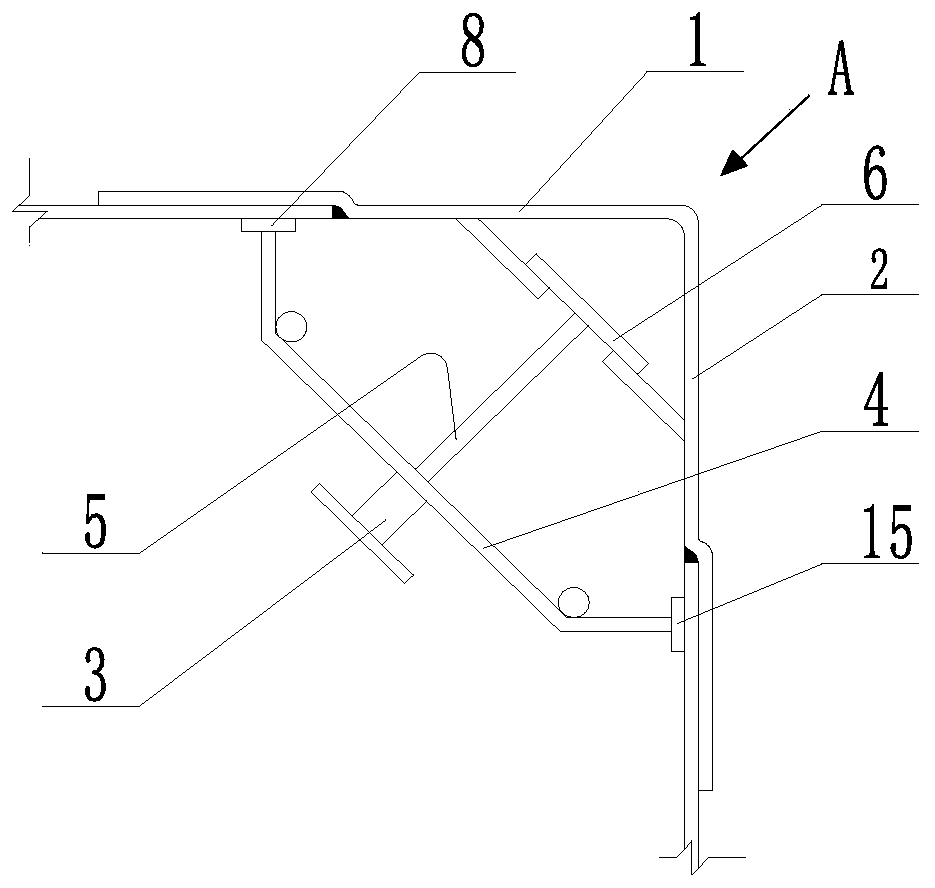

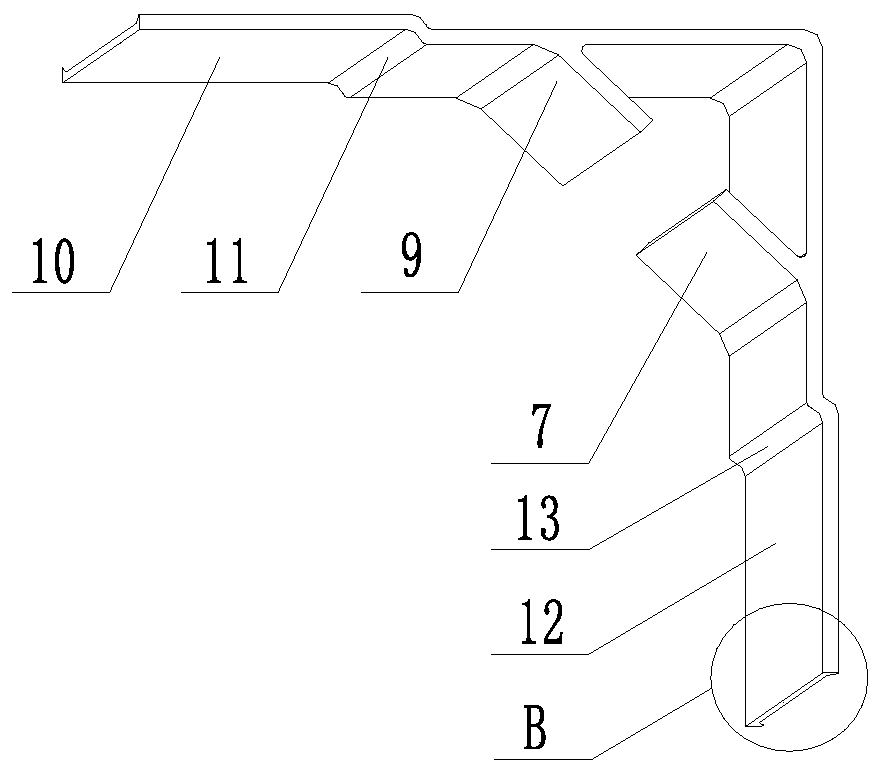

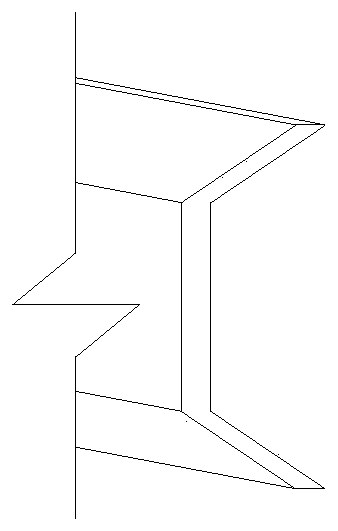

[0042] Such as Figures 1 to 6 As shown, a corner waterproof steel plate equipped with a fixing device, a waterproof groove is opened on the outside of the corner waterproof steel plate, including a first right-angle plate 1 and a second right-angle plate 2; one end of the first right-angle plate 1 is connected to the second right-angle One end of the plate 2 is connected by welding; the other end of the first right-angle plate 1 is welded and connected with the first welded plate 10; the other end of the second right-angle plate 2 is welded and connected with the second welded plate 12; the first right-angle plate 1 is welded to the first The plates 10 are arranged in parallel; the first right-angle plate 1 and the first welded plate 10 are provided with a first notch 11 at the joint; the second right-angle plate 2 is arranged in parallel with the second welded plate 12; The board 12 is provided with a second notch 13 at the joint; the first notch 11 and the second notch 13 b...

Embodiment 2

[0047] A construction method of a corner waterproof steel plate equipped with a fixing device, comprising the following steps:

[0048] Step 1. Preparation

[0049] According to the drawing design requirements, mark the installation datum line on the reinforcement;

[0050] Step 2. Installation of corner waterproof steel plate

[0051] S1. Place the corner waterproof steel plate inside the steel bar at the pre-installation position, and place the waterproof groove on the water-facing surface;

[0052] S2, docking the first welded plate 10 and the second welded plate 12 with the corresponding waterproof steel plate;

[0053] Step 3: Fix the corner waterproof steel plate with the fixing device

[0054] H1. Place the first pressure plate 6 on the side of the first fixed plate 9 and the second fixed plate 7 close to the first right-angle plate 1 and the second right-angle plate 2, and place the first positioning pin 16 on the first fixed plate 9 Cooperate with the first positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com