Ultraviolet-cured silicone rubber for DIW (direct ink writing) 3D (three-dimensional) printing and preparation method thereof

A technology for curing silicone rubber and ultraviolet light, applied in the direction of additive processing, etc., can solve the problems of reducing the high and low temperature resistance of silicone rubber, expensive photosensitive platinum catalyst, and difficult to achieve mechanical properties, etc. Precision controllability, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

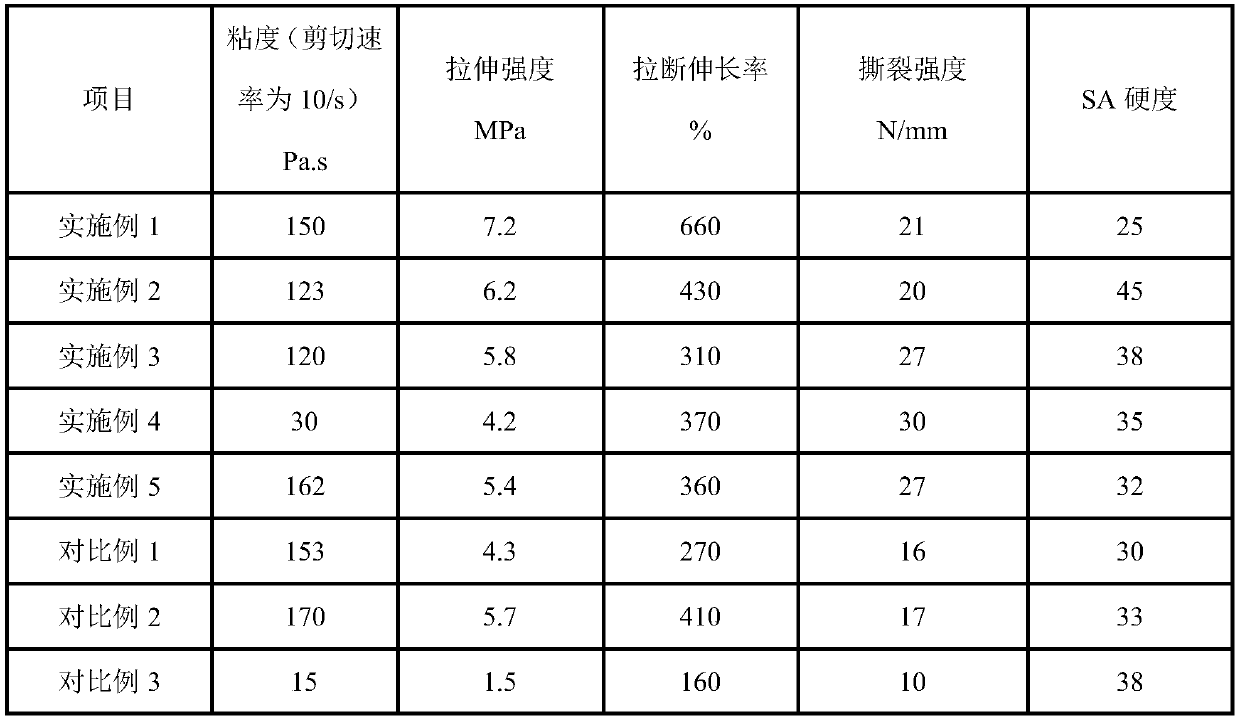

Examples

Embodiment 1

[0043] The preparation method of the ultraviolet curing silicone rubber for DIW3D printing, the steps are as follows:

[0044] Take 30g of vinyl-terminated polydimethylsiloxane with a viscosity of 20000mpas, 1.5g of side chain mercaptopropylpolysiloxane, 10g of fumed silica H2000, 3g of hydroxyl-terminated polysiloxane with a viscosity of 2000mPa.s, 5 g of methyl MQ silicone resin and 0.1 g of diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide (TPO) were mixed at 25° C. for 30 minutes to obtain UV-curable silicone rubber.

Embodiment 2

[0046] The preparation method of the ultraviolet curing silicone rubber for DIW3D printing, the steps are as follows:

[0047] Take 30g of vinyl-terminated polydimethylsiloxane, 1.5g of side chain mercaptopropyl polysiloxane, 8g of fumed silica H2000, 3g of diatomaceous earth with a viscosity of 20000mpas, and ether group-containing polysiloxane with a viscosity of 2000mPa.s. 2g of siloxane, 5g of methyl MQ silicone resin, 0.1g of diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide (TPO), mixed at 25°C for 30 minutes to obtain UV-curable silicone rubber.

Embodiment 3

[0049] The preparation method of the ultraviolet curing silicone rubber for DIW3D printing, the steps are as follows:

[0050] Take the vinyl-terminated polydimethylsiloxane 40g, side chain mercaptopropyl polysiloxane 1.5g, fumed silica 10g, vinyl MQ silicone resin 7g, viscosity 2000mPa. 3 g of base polysiloxane and 0.1 g of benzoin dimethyl ether were mixed at 25° C. for 30 minutes to obtain a UV-curable silicone rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com