Landfill leachate treatment method and system

A technology for landfill leachate and a treatment method, which is applied in the field of landfill leachate treatment methods and systems, can solve the problem of high operating costs and achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Such as figure 1 , the embodiment of the present invention provides a landfill leachate treatment method, comprising the following steps:

[0029] S1, performing hydrolysis and acidification treatment on the leachate;

[0030] S2, denitrifying the leachate;

[0031] S3, nitrifying the leachate;

[0032] S4, the leachate after nitrification treatment is subjected to biochemical precipitation treatment;

[0033] S5, the supernatant obtained from the biochemical precipitation treatment is subjected to the first-stage membrane filtration treatment;

[0034] S6, performing oxidation treatment on the filtrate after the first-stage membrane filtration treatment;

[0035] In S7, the oxidized effluent is subjected to second-stage membrane filtration treatment to obtain a standard discharge liquid.

[0036] In the above method, specifically:

[0037] COD of landfill leachate cr High (up to 00-00mg / L), large organic load. In S1, hydrolytic acidification treatment can effec...

Embodiment 2

[0067] Such as figure 1 , the embodiment of the present invention provides a landfill leachate treatment system, including oil removal unit 100, hydrolytic acidification unit 200, denitrification unit 400, 300, nitrification unit 400, biochemical precipitation unit 500, first stage Membrane filtration unit 600 , oxidation unit 700 and second-stage membrane filtration unit 800 , the degreasing unit 100 is provided with a leachate inlet pipe, and the second-stage membrane filtration unit 800 is provided with a standard outlet pipe.

[0068] Wherein, the above-mentioned degreasing unit 100 is preferably an air flotation degreasing unit 100, and the degreasing effect is better.

[0069] The structure of the above-mentioned oil removal unit 100, hydrolysis acidification unit 200, denitrification unit 400, 300, nitrification unit 400, biochemical precipitation unit 500, first-stage membrane filtration unit 600, oxidation unit 700 and second-stage membrane filtration unit 800 can ref...

Embodiment 3

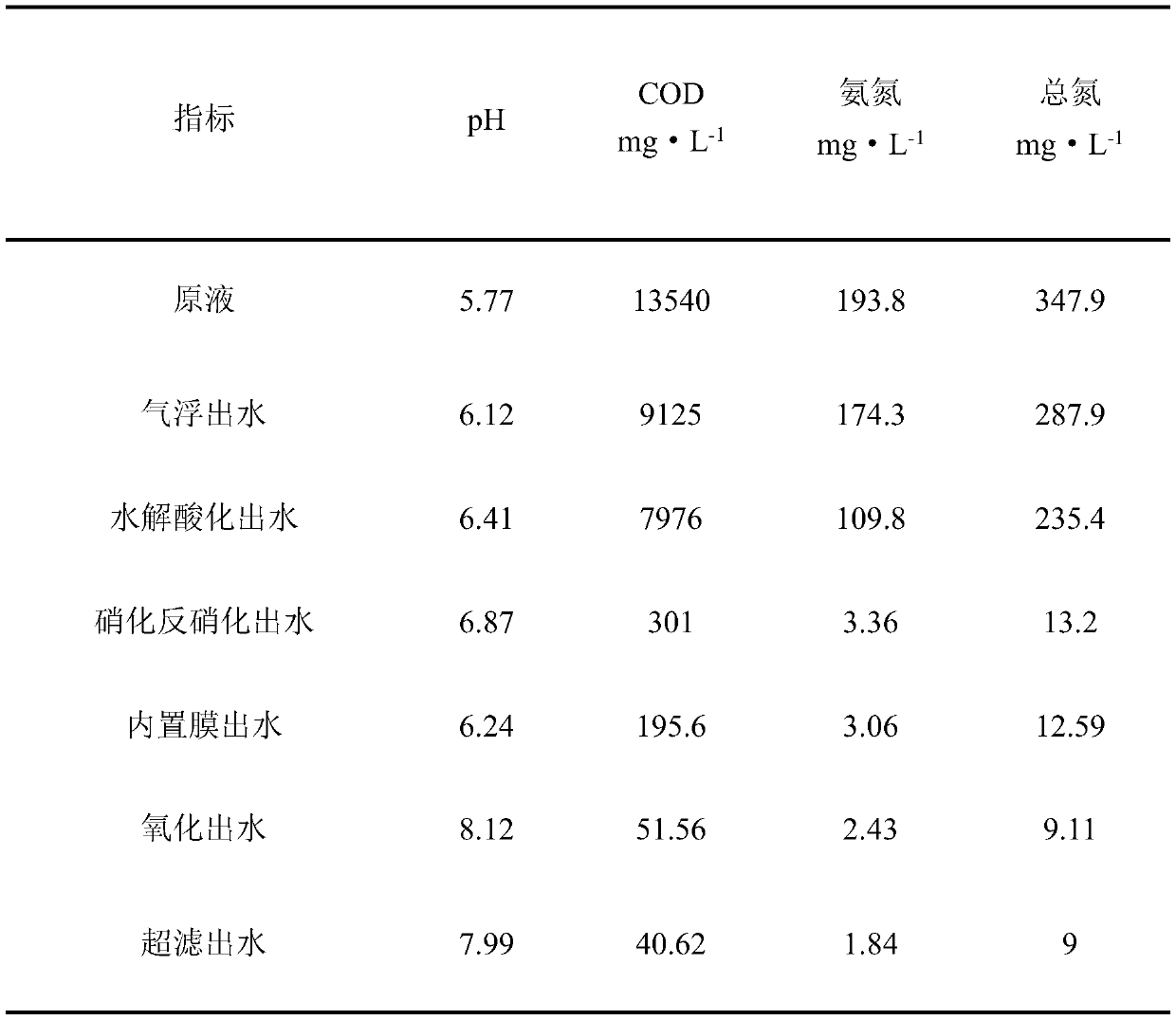

[0082] The above landfill leachate treatment method and system are described below with specific application examples:

[0083] For the leachate of a small garbage transfer station, the above-mentioned landfill leachate treatment method is used for treatment:

[0084] First, the landfill leachate stock solution enters the air flotation reaction zone of the air flotation degreasing unit 100, and ferrous sulfate heptahydrate and PAM (polyacrylamide) are added in the air flotation reaction zone, and the configuration concentration of ferrous sulfate heptahydrate is 20%. Gabi 10L / m 3 ; PAM configuration concentration 0.1%, dosing ratio 10L / m 3 , react for 5 minutes, enter the air flotation contact zone for steam-water mixing, then enter the air flotation separation zone, the total residence time of the air flotation degreasing unit 100 is 30 minutes, COD cr The removal rate is 32.6%, the removal rate of ammonia nitrogen is 10.1%, and the removal rate of total nitrogen is 17.2%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com