Polymer-modified mesoporous carbon nanoparticle and preparation and application thereof

A mesoporous carbon and polymer technology, applied in the field of medicine, can solve the problems of poor water solubility, low bioavailability, and the treatment of diseases that affect the clinical efficacy of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

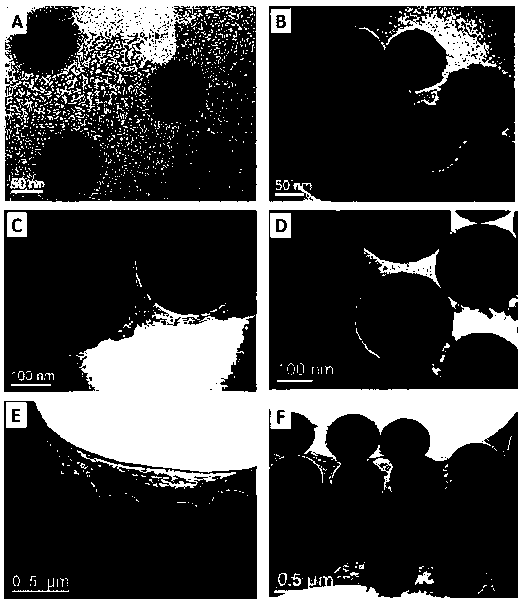

Image

Examples

Embodiment 1

[0052] Add 20mL of distilled water, 0.1mL of ammonia water, 4mL of absolute ethanol and 1g of 25% CTAC solution into the Erlenmeyer flask, stir at room temperature for 20min, then add 0.2g of resorcinol and continue stirring for 30min. Measure 0.36mL tetraethyl orthosilicate (TEOS) and 0.28mL formaldehyde solution and add dropwise to the above reaction solution, place in a water bath and heat to 30°C, and keep stirring for 24h. After the reaction, the obtained product was centrifuged, washed twice with distilled water and absolute ethanol, and the precipitate was collected and dried in an oven. The resulting solid was ground, sieved, and 2 Carbon-silicon mixture was obtained by carbonizing at a high temperature of 700° C. for 3 hours under the same conditions, and soaking the carbon-silicon mixture in 10% hydrofluoric acid solution for 24 hours to remove the silica template to obtain spherical mesoporous carbon.

Embodiment 2

[0054] Add 20 mL of distilled water, 0.1 mL of ammonia water, 6 mL of absolute ethanol and 1 g of 25% CTAC solution into the Erlenmeyer flask, stir at room temperature for 20 min, then add 0.2 g of resorcinol and continue stirring for 30 min. Measure 0.36mL tetraethyl orthosilicate (TEOS) and 0.28mL formaldehyde solution and add dropwise to the above reaction solution, place in a water bath and heat to 30°C, and keep stirring for 24h. After the reaction, the obtained product was centrifuged, washed twice with distilled water and absolute ethanol, and the precipitate was collected and dried in an oven. The resulting solid was ground, sieved, and 2 Carbon-silicon mixture was obtained by carbonizing at a high temperature of 700° C. for 3 hours under the same conditions, and soaking the carbon-silicon mixture in 10% hydrofluoric acid solution for 24 hours to remove the silica template to obtain spherical mesoporous carbon.

Embodiment 3

[0056] Add 20mL of distilled water, 0.1mL of ammonia water, 8mL of absolute ethanol and 1g of 25% CTAC solution into the Erlenmeyer flask, stir at room temperature for 20min, then add 0.2g of resorcinol and continue stirring for 30min. Measure 0.36mL tetraethyl orthosilicate (TEOS) and 0.28mL formaldehyde solution and add dropwise to the above reaction solution, place in a water bath and heat to 30°C, and keep stirring for 24h. After the reaction, the obtained product was centrifuged, washed twice with distilled water and absolute ethanol, and the precipitate was collected and dried in an oven. The resulting solid was ground, sieved, and 2 Carbon-silicon mixture was obtained by carbonizing at a high temperature of 700° C. for 3 hours under the same conditions, and soaking the carbon-silicon mixture in 10% hydrofluoric acid solution for 24 hours to remove the silica template to obtain spherical mesoporous carbon.

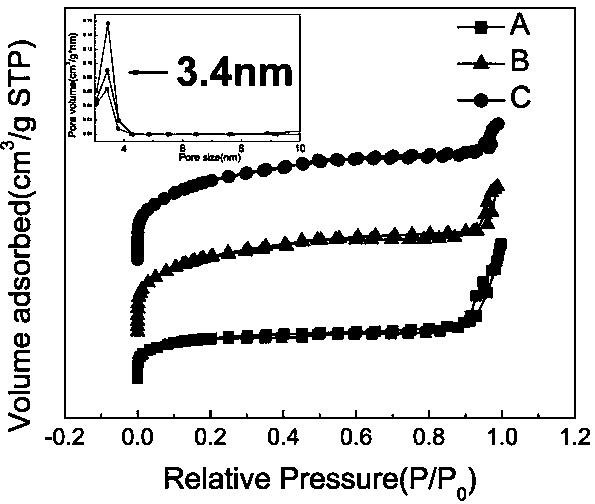

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com