High-temperature heat pump system with water as working medium for industrial wastewater waste heat recovery and control method of high-temperature heat pump system

A technology for industrial waste water and waste heat recovery, which is applied in heat recovery systems, heating systems, and hot water central heating systems, and can solve problems such as the inability to meet the heating demand of industrial production and the destruction of the ozone layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] System embodiment

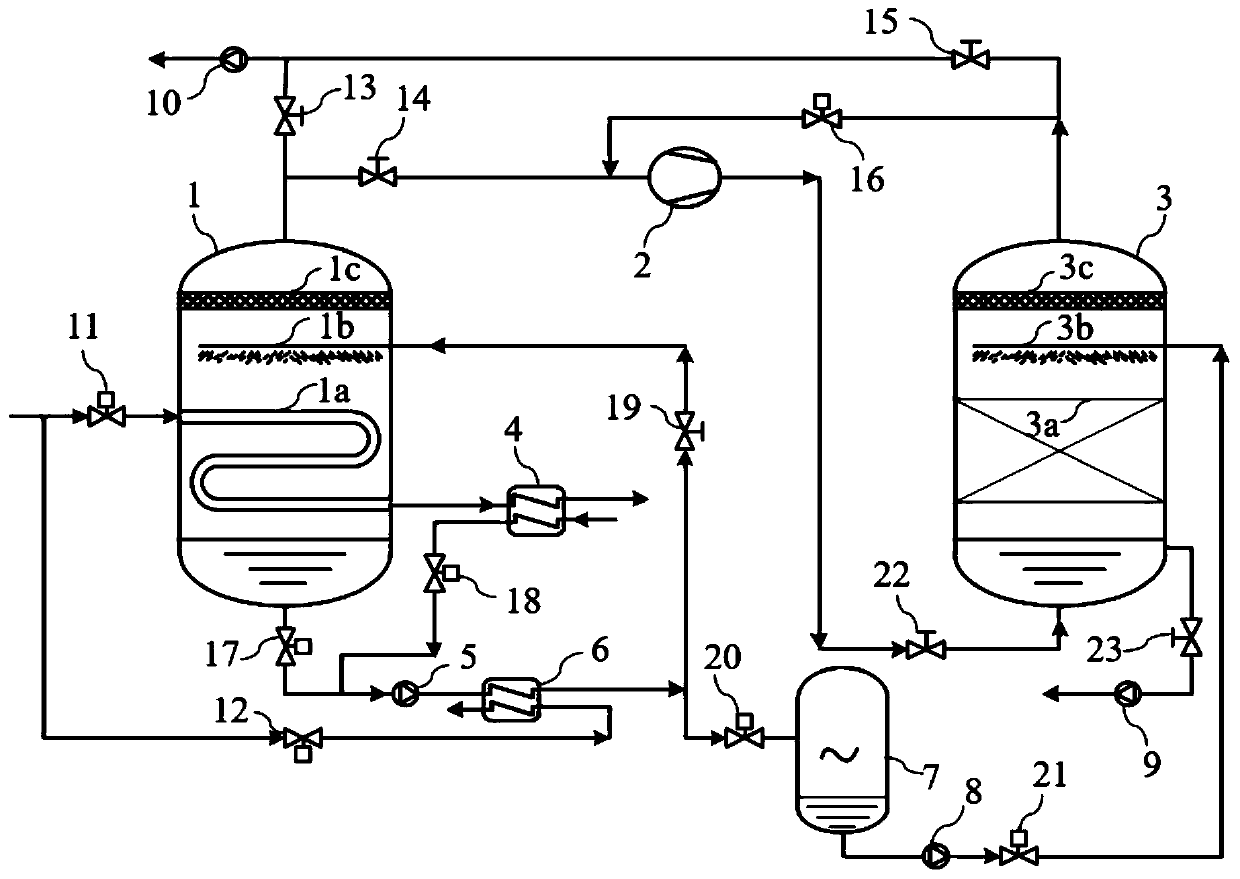

[0034] Such as figure 1 Shown: a high-temperature heat pump system using water as the working medium for recovery of waste heat from industrial wastewater, including an evaporator 1, a water vapor compressor 2, a contact condenser 3, a first heat exchanger 4, a feed water pump 5, The second heat exchanger 6, the electric hot water tank 7 and the spray water pump 8, the evaporator 1 is equipped with a heat exchange tube 1a, a spray tube 1b, and a filter screen 1c, and the industrial waste water above 50°C is passed in the heat exchange tube 1a, The spray water 1b sprays the heated make-up water, and the filter screen 1c is used to filter out the liquid droplets in the steam;

[0035] Described contact condenser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com