Large-headroom restorable-function steel-framed centrally-braced system

A technology for central support system and restoration of functions, applied in building components, building types, earthquake resistance, etc., can solve problems such as frame openings and openings, and achieve the effect of improving lateral force resistance, lateral force resistance, and flexible design forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

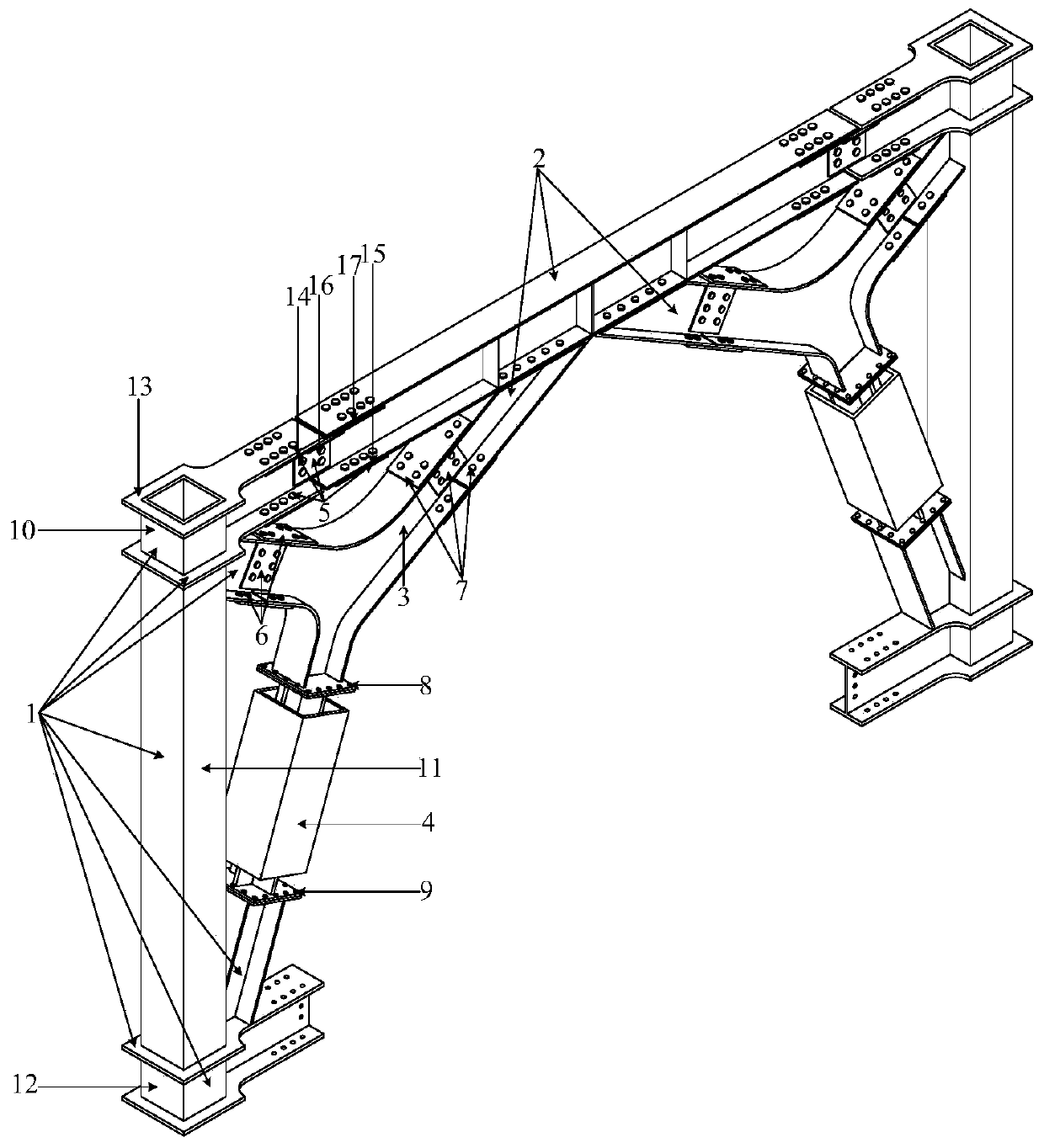

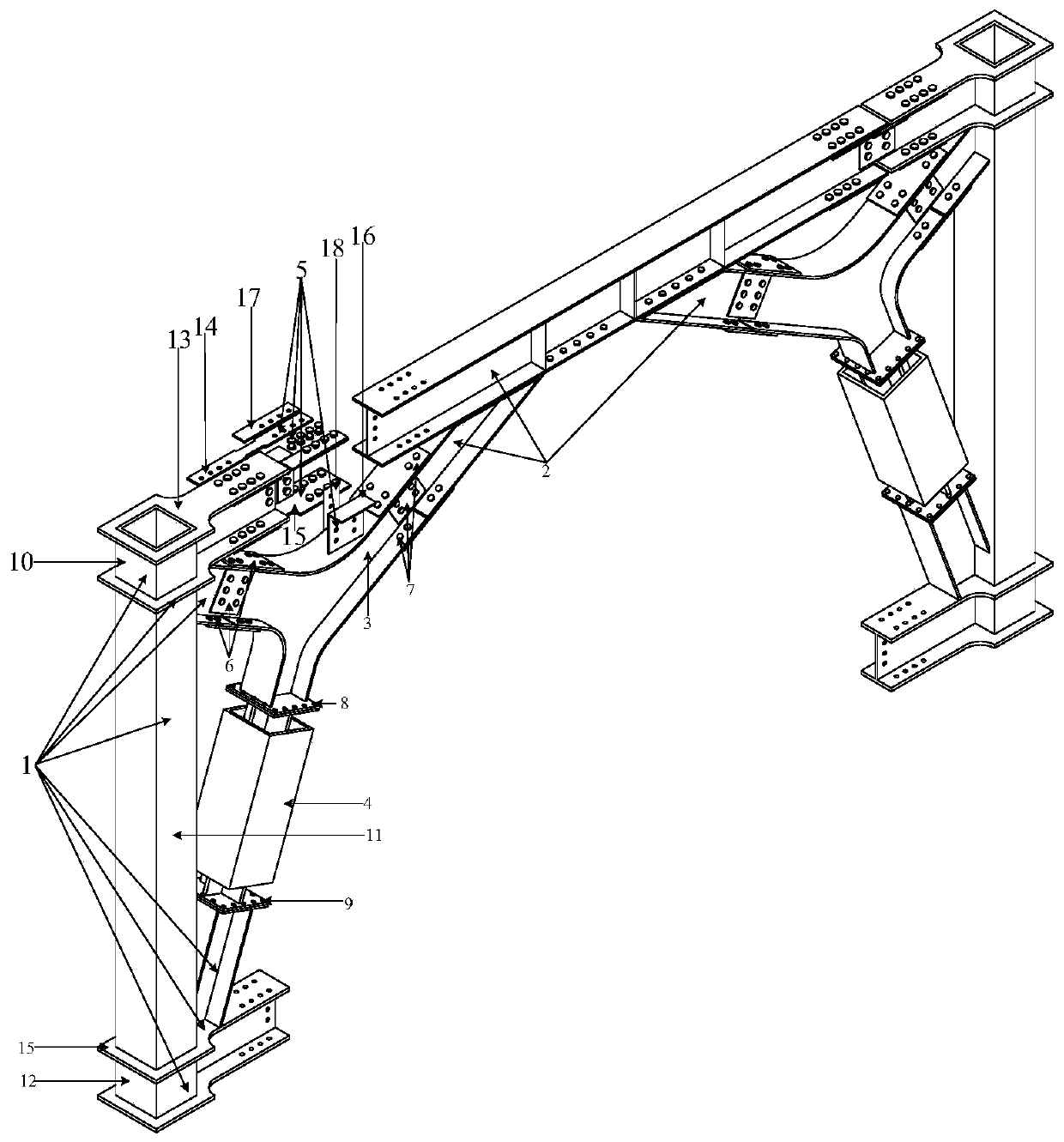

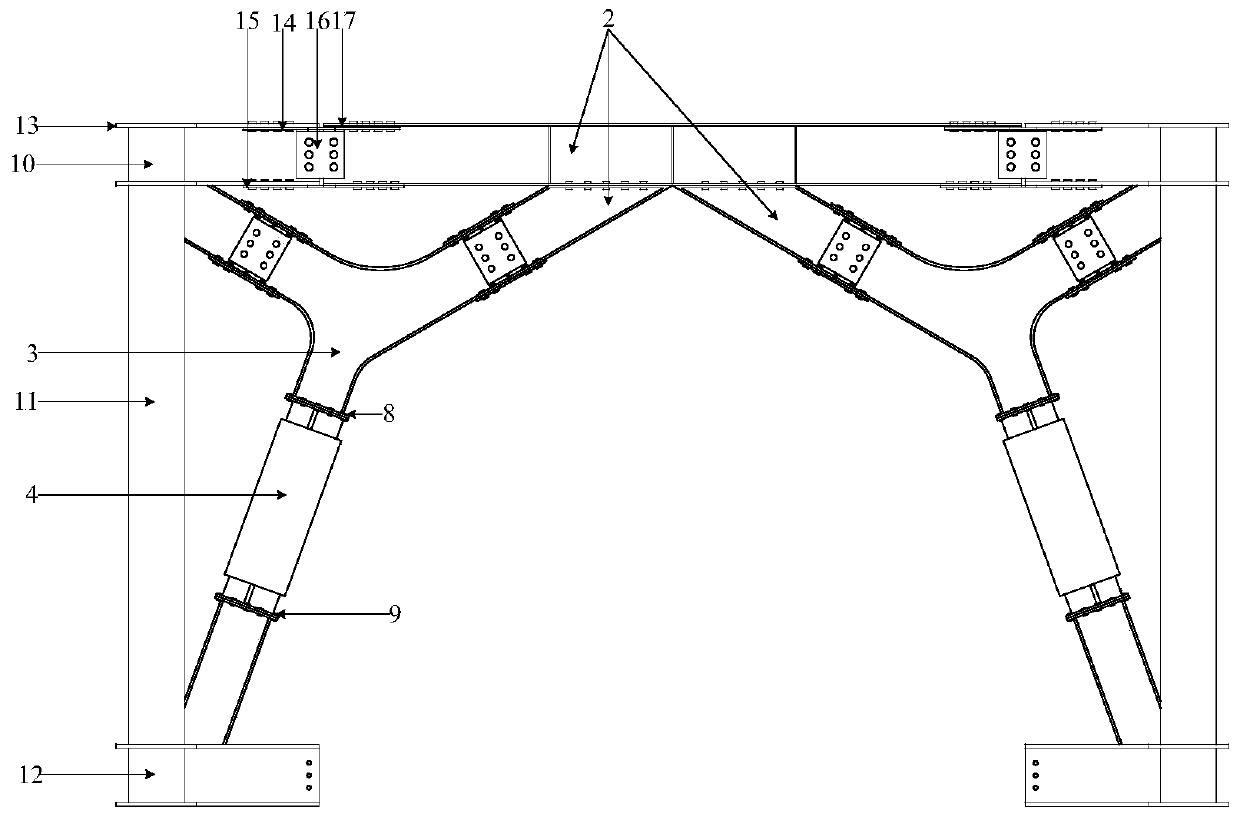

[0022] Attached below Figure 1-7 , detailing the implementation of this patent.

[0023] Such as Figure 1-7 As shown, a steel frame central support system that can open the door includes the following components:

[0024] 1——Welded combined square steel pipe column;

[0025] 2——I-beam section with oblique support rod;

[0026] 3——Y-type diagonal brace;

[0027] 4——Slant bracing energy consumption section;

[0028] 5 - the first connecting device;

[0029] 6 - the second connecting device;

[0030] 7 - the third connecting device;

[0031] 8 - the fourth connecting device;

[0032] 9 - the fifth connecting device;

[0033] 10——Square steel pipe upper column;

[0034] 11——Square steel pipe center column;

[0035] 12——The lower column of the square steel pipe;

[0036] 13 - cantilever beam section;

[0037] 14——upper flange inner cover;

[0038] 15——The outer cover plate of the lower flange;

[0039] 16——inverted L-shaped web shear plate;

[0040] 17——The backin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com