Anti-leakage protective film

A protective film, leak-proof technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve problems such as affecting the quality of the protected product, poor toughness or ductility, rupture of PE protective film, etc., to avoid ductility Excessive size, high ductility and toughness, avoid aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

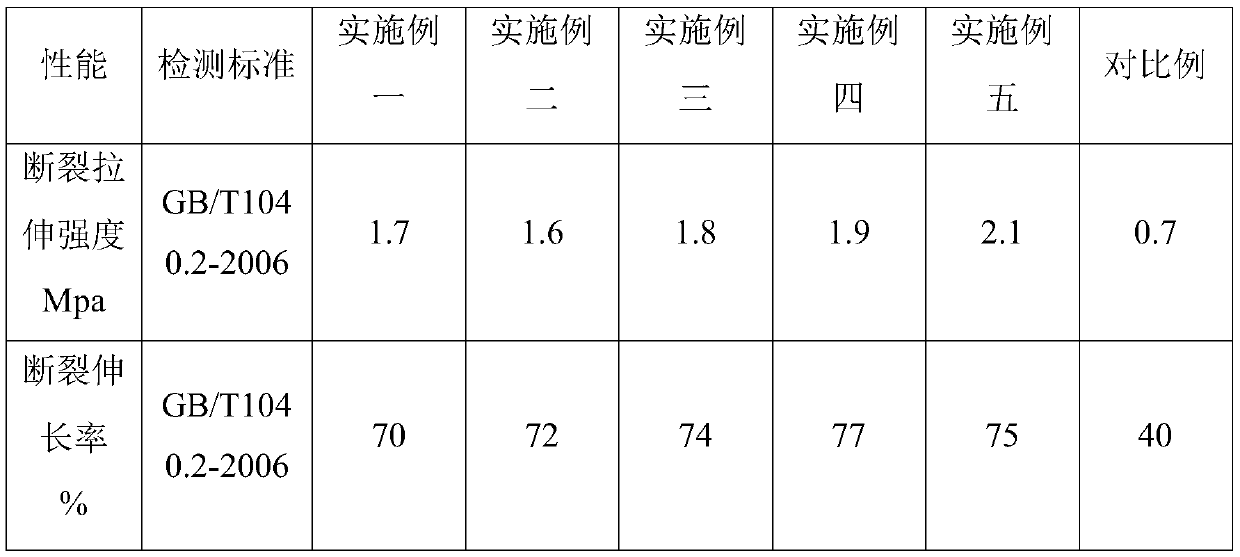

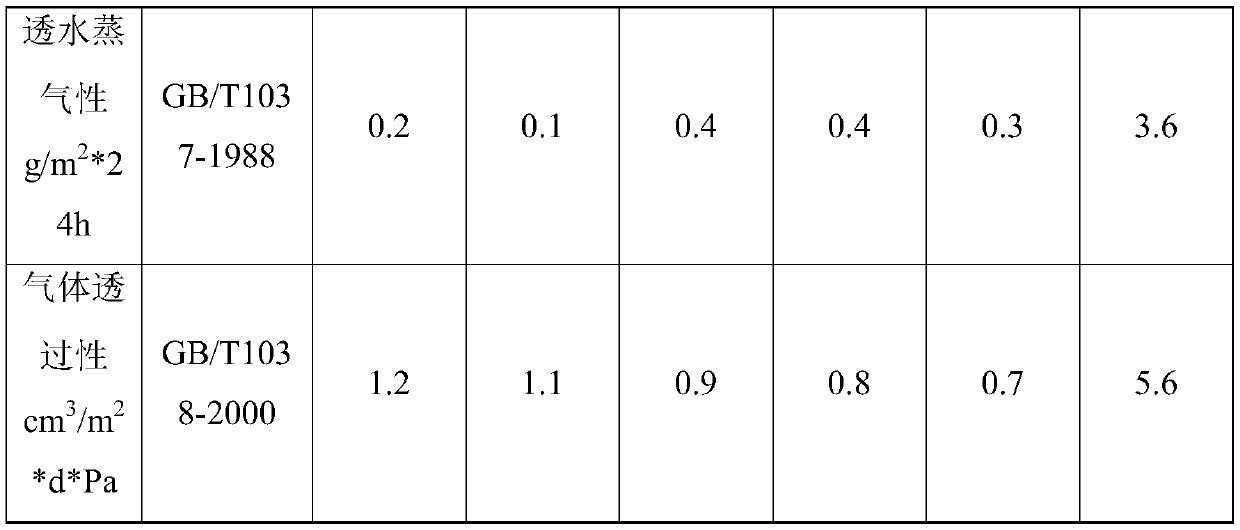

Examples

Embodiment 1

[0035] A leak-proof protective film, comprising a PE base layer with the same thickness, an adhesive layer, an extension layer and a barrier layer;

[0036] The raw materials of the PE base layer include the following parts by weight: the density is 0.91g / cm 3 45 parts of low-density polyethylene, 25 parts of toughening agent, 12 parts of stabilizer;

[0037] The raw materials of the extension layer include the following parts by weight: 35 parts of polylactic acid, 14 parts of compatibilizer ethylene ethyl acrylate;

[0038] The raw materials of the barrier layer include the following parts by weight: 26 parts of polyethylene terephthalate and 12 parts of polycarbonate.

[0039] in:

[0040] The toughening agent is chlorinated polyethylene with a chlorine content of 26% by mass ratio or an ethylene-vinyl acetate copolymer whose ratio of x and y in (C2H4)x(C4H6O2)y is 5:3;

[0041] The stabilizer is a mixture of 5 parts of benzotriazole and 7 parts of carbon black.

[0042] ...

Embodiment 2

[0048] A leak-proof protective film, comprising a PE base layer with the same thickness, an adhesive layer, an extension layer and a barrier layer;

[0049] The raw materials of the PE base layer include the following parts by weight: the density is 0.912g / cm 3 50 parts of low-density polyethylene, 27 parts of toughening agent, 15 parts of stabilizer;

[0050] The raw materials of the extension layer include the following parts by weight: 40 parts of polylactic acid, 16 parts of compatibilizer ethylene ethyl acrylate;

[0051] The raw materials of the barrier layer include the following parts by weight: 28 parts of polyethylene terephthalate, and 15 parts of polycarbonate.

[0052] in:

[0053] The toughening agent is chlorinated polyethylene with a chlorine content of 30% by mass ratio or an ethylene-vinyl acetate copolymer whose ratio of x and y in (C2H4)x(C4H6O2)y is 6:4;

[0054] The stabilizer is a mixture of 6 parts of benzotriazole and 8 parts of carbon black.

[00...

Embodiment 3

[0061] A leak-proof protective film, comprising a PE base layer with the same thickness, an adhesive layer, an extension layer and a barrier layer;

[0062] The raw materials of the PE base layer include the following parts by weight: 55 parts of low-density polyethylene with a density of 0.914g / cm3, 30 parts of toughening agent, and 20 parts of stabilizer;

[0063] The raw materials of the extension layer include the following parts by weight: 45 parts of polylactic acid, 20 parts of compatibilizer ethylene ethyl acrylate;

[0064] The raw materials of the barrier layer include the following parts by weight: 30 parts of polyethylene terephthalate, and 20 parts of polycarbonate.

[0065] in:

[0066] The toughening agent is chlorinated polyethylene with a chlorine content of 32% by mass ratio or an ethylene-vinyl acetate copolymer whose ratio of x and y in (C2H4)x(C4H6O2)y is 7:4;

[0067] The stabilizer is a mixture of 8 parts of benzotriazole and 10 parts of carbon black. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com