ABS alloy material easy to clean and preparation method thereof

An alloy material, easy-to-clean technology, applied in the field of easy-to-clean ABS alloy materials and its preparation, to prevent long-term accumulation, not easy to accumulate dust, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

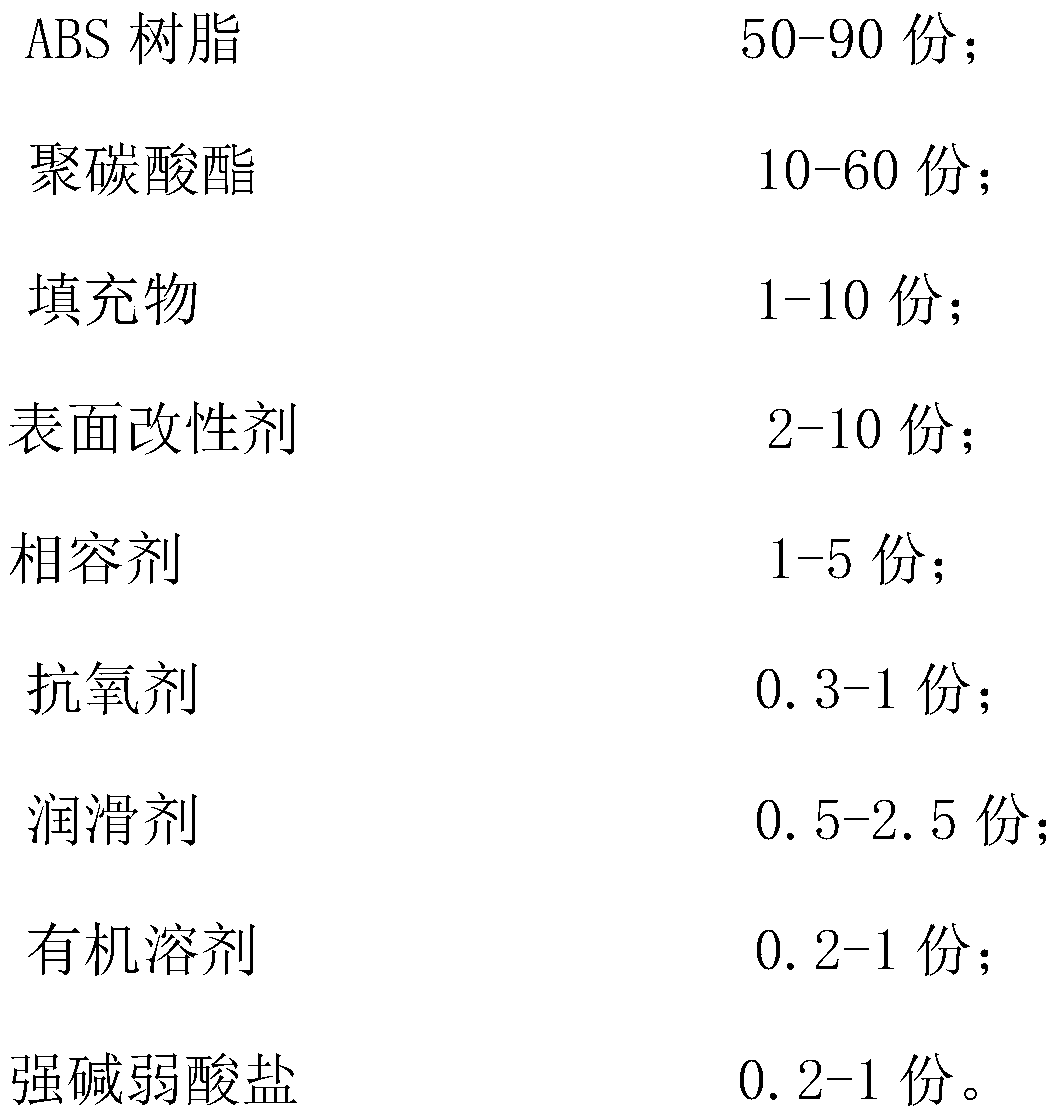

[0028] An easy-to-clean ABS alloy material and a preparation method thereof, characterized in that: the alloy material is prepared from the following components in parts by weight:

[0029]

[0030] A kind of preparation method of easy-to-clean ABS alloy material is as follows:

[0031] (1) Mix polycarbonate with strong base and weak salt to obtain a mixture, and then place the mixture in a reactor under low pressure (30Pa) (the outer wall of the reactor is a stainless steel circular container, and two parallel diameters are installed in the center of the reaction chamber. Disc electrodes with a distance of 25 cm and a distance of 10 cm, the upper plate and the container wall are grounded, and the lower plate is connected to a radio frequency power supply) and treated with CF4 radio frequency plasma for 20 minutes;

[0032] (2) Put the polycarbonate treated in step (1) and the mixture of strong base and weak acid salt into the screw extruder, and at the same time, put ABS r...

Embodiment 2

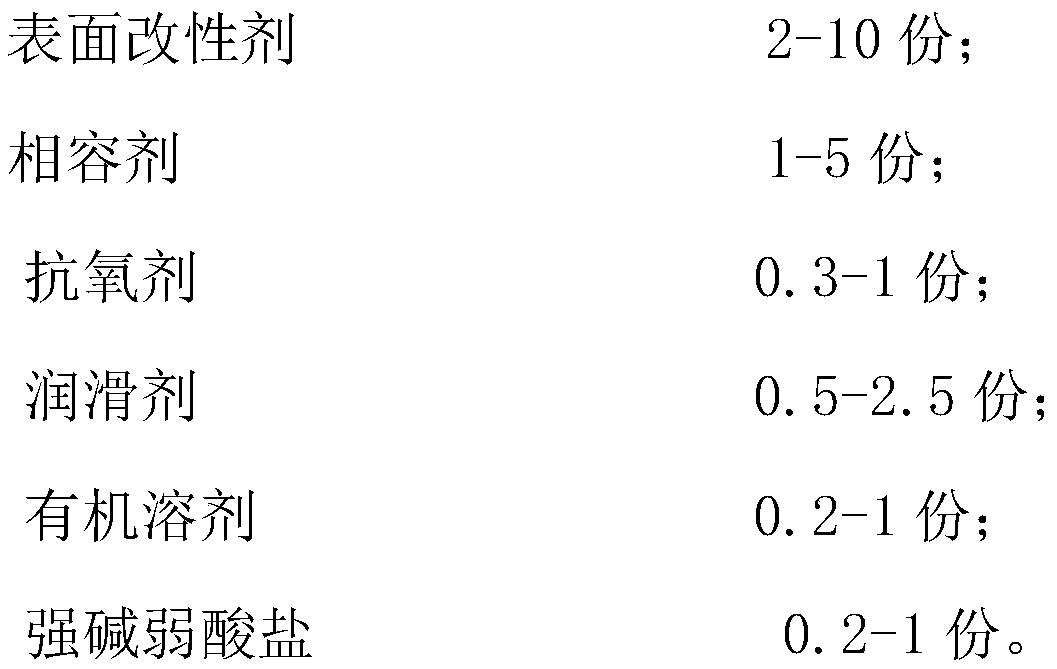

[0035]

[0036]

[0037] A kind of preparation method of easy-to-clean ABS alloy material is as follows:

[0038] (1) Mix polycarbonate with strong base and weak salt to obtain a mixture, and then place the mixture in a reactor under low pressure (30Pa) (the outer wall of the reactor is a stainless steel circular container, and two parallel diameters are installed in the center of the reaction chamber. Disc electrodes with a distance of 25 cm and a distance of 10 cm, the upper plate and the container wall are grounded, and the lower plate is connected to a radio frequency power supply) and treated with CF4 radio frequency plasma for 20 minutes;

[0039] (2) Put the polycarbonate treated in step (1) and the mixture of strong base and weak acid salt into the screw extruder, and at the same time, put ABS resin, filler, surface modifier, phase modifier into the screw extruder Compatible agent, antioxidant and lubricant, through melt extrusion and pelletizing, to obtain prima...

Embodiment 3

[0042]

[0043]

[0044] A kind of preparation method of easy-to-clean ABS alloy material is as follows:

[0045] (1) Mix polycarbonate with strong base and weak salt to obtain a mixture, and then place the mixture in a reactor under low pressure (30Pa) (the outer wall of the reactor is a stainless steel circular container, and two parallel diameters are installed in the center of the reaction chamber. Disc electrodes with a distance of 25 cm and a distance of 10 cm, the upper plate and the container wall are grounded, and the lower plate is connected to a radio frequency power supply) and treated with CF4 radio frequency plasma for 20 minutes;

[0046] (2) Put the polycarbonate treated in step (1) and the mixture of strong base and weak acid salt into the screw extruder, and at the same time, put ABS resin, filler, surface modifier, phase modifier into the screw extruder Compatible agent, antioxidant and lubricant, through melt extrusion and pelletizing, to obtain prima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com