Stabilizer, preparation method thereof, preparation method and application of polymer polyhydric alcohol

A technology of oligomer polyol and polyether polyol, which is applied in the field of stabilizer preparation and can solve problems such as gelation and agglomeration, difficult reaction stages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

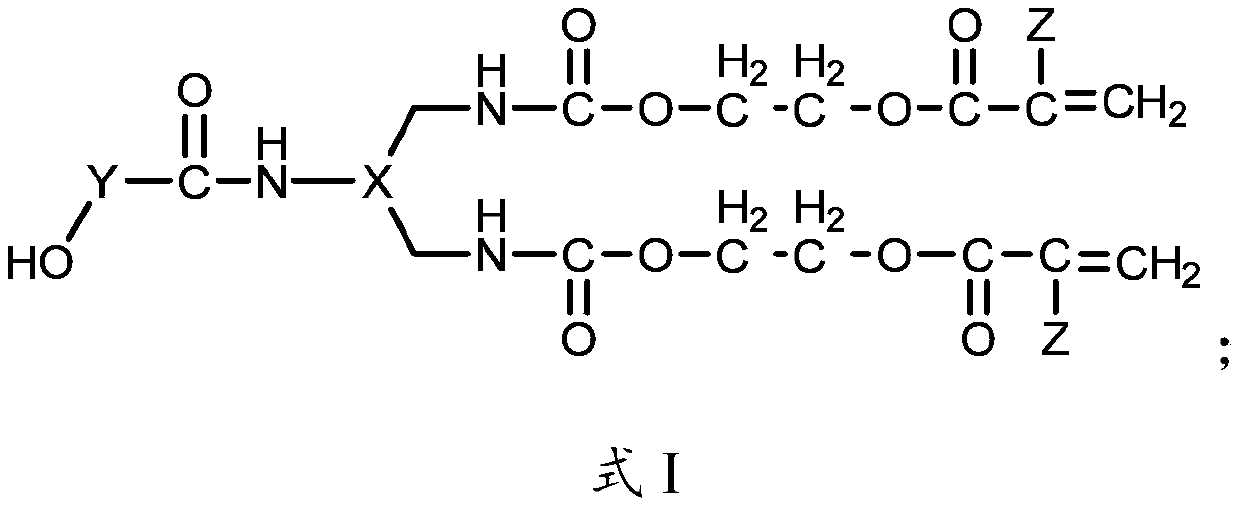

[0071] Prepolymer synthesis: add 43.5g TDI-Trimer (TDI trimer 50% (w / w) butyl acetate solution) and 0.15g dibutyltin dilaurate (DBTDL) catalyst in the there-necked flask, start stirring, adjust The temperature in the reaction system was 45°C; when the temperature reached 45°C, 10.8g of HEMA (hydroxyethyl methacrylate) was slowly added dropwise, and the reaction was stopped after 4 hours to obtain a prepolymer.

[0072] Stabilizer synthesis: drop 500g of polyether polyol A into the above prepolymer, react for 2 hours, raise the temperature to 80°C, detect the reaction progress by infrared absorption spectrum, and reach 2261cm -1(s, N=C=O) until the absorption peak disappears, react for another 1h; add phosphoric acid to inactivate, remove the volatile solvent butyl acetate, and obtain the stabilizer ①; its viscosity is 3318cp@25°C, and the degree of unsaturation is 0.065 meq / g.

Embodiment 2

[0074] Prepolymer synthesis: Add 36.4g of HDI biuret and 60ml of toluene (dehydrated with 4A molecular sieve in advance) into a three-necked flask, then add 0.15g of dibutyltin dilaurate (DBTDL) catalyst, start stirring, and slowly heat up to 60°C ; When the temperature reaches 60°C, slowly add 20.6g HEMA (hydroxyethyl methacrylate) dropwise, control the reaction temperature in the system to ±2°C, stop the reaction after 4h, and obtain a prepolymer.

[0075] Stabilizer synthesis: drop 500g of polyether polyol B into the above prepolymer, react for 2 hours, raise the temperature to 100°C, detect the reaction progress by infrared absorption spectrum, and reach 2261cm -1 (s, N=C=O) until the absorption peak disappears, react for another 1h; add phosphoric acid to inactivate, remove the volatile solvent butyl acetate, and obtain the stabilizer ②; its viscosity is 2950cp@25°C, and the degree of unsaturation is 0.089 meq / g.

Embodiment 3

[0080] Preparation of polymer polyol 1: a 500ml four-necked bottle is equipped with a stirrer, a heating device, a temperature control device and a feeder as a reactor; add basic polyether polyol C (Wanhua 3156) 55.4g, 3.9g stabilizer ①, after nitrogen replacement, stir slowly and heat up to 110°C, then continuously add top material (10.47g isopropanol, 85.71g basic polyether polyol C 3156, a mixture of 46.55g acrylonitrile, 69.83g styrene, and 1.21g azobisisobutyronitrile), and the temperature is controlled at 115°C to 120°C. The dropwise addition was completed within 100 minutes, the feeding was completed, the aging reaction was carried out for 1 hour, and the vacuum monomer removal was continued for 2 hours to obtain the product and measure the product index. The hydroxyl value of the obtained polymer polyol 1 is 29.4 mgKOH / g, the solid content is 44.8%, and the viscosity is 4959 mPa·S; after adding 3% (w / w) water to the polymer polyol 1, its viscosity becomes 5183 mPa ·...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com