Phase-change self-temperature-control cement foaming heat preservation board and production method thereof

A technology of cement foaming and self-temperature control, which is applied to other home appliances, applications, home appliances, etc. It can solve the problems of low heat storage capacity indoor temperature and insignificant energy saving effect, and achieve improved heat storage capacity and good temperature delay Performance and self-temperature control ability, the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A phase-change self-controlling temperature cement foam insulation board, the preparation of which comprises the following steps:

[0014] Raw materials: cement 50kg, fly ash 30kg, phase change material 10kg, polypropylene fiber 0.3kg, cellulose ether 15g, water 32kg, hydrogen peroxide 5.5kg, alkaline waterproof foam stabilizer 5kg

[0015] Preparation of materials: put water, alkaline waterproof foam stabilizer, polypropylene fiber, and cellulose ether in a mixing device and stir for 10 seconds, then add ordinary Portland cement, fly ash, and phase change materials and stir for 3 minutes until the Mix it into a homogeneous slurry, then add hydrogen peroxide, stir rapidly for 10 seconds, immediately pour the slurry into a mold for foaming and molding, and cure it under natural conditions for 1 day until a certain strength is formed, remove the mold, and cut it to obtain a Phase change self-control temperature cement foam insulation board.

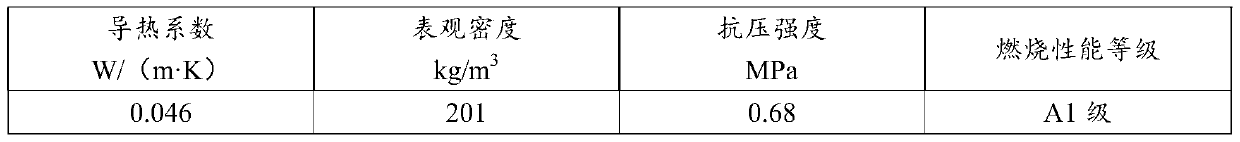

[0016] Material performance ...

Embodiment 2

[0019] Raw materials: cement 60kg, fly ash 20kg, phase change material 10kg, polypropylene fiber 0.3kg, cellulose ether 15g, water 33kg, hydrogen peroxide 5.5kg, alkaline waterproof foam stabilizer 5kg

[0020] Preparation of materials: put water, alkaline waterproof foam stabilizer, polypropylene fiber, and cellulose ether in a mixing device and stir for 10 seconds, then add ordinary Portland cement, fly ash, and phase change materials and stir for 3 minutes until the Mix it into a homogeneous slurry, then add hydrogen peroxide, stir rapidly for 10 seconds, immediately pour the slurry into a mold for foaming and molding, and cure it under natural conditions for 1 day until a certain strength is formed, remove the mold, and cut it to obtain a Phase change self-control temperature cement foam insulation board.

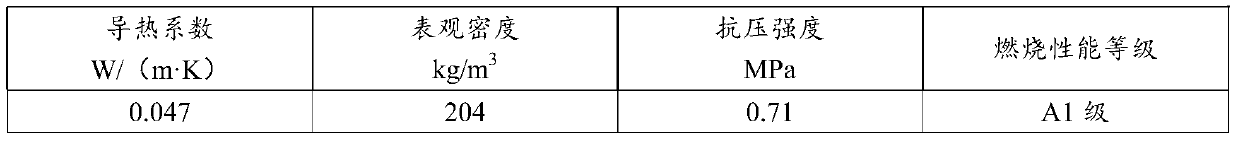

[0021] Material performance indicators:

[0022]

Embodiment 3

[0024] A phase-change self-controlling temperature cement foam insulation board, the preparation of which comprises the following steps:

[0025] Raw materials: 70kg of cement, 10kg of fly ash, 10kg of phase change material, 0.3kg of polypropylene fiber, 15g of cellulose ether, 34kg of water, 5.5kg of hydrogen peroxide, 5kg of alkaline waterproof foam stabilizer

[0026] Preparation of materials: put water, alkaline waterproof foam stabilizer, polypropylene fiber, and cellulose ether in a mixing device and stir for 10 seconds, then add ordinary Portland cement, fly ash, and phase change materials and stir for 3 minutes until the Mix it into a homogeneous slurry, then add hydrogen peroxide, stir rapidly for 10 seconds, immediately pour the slurry into a mold for foaming and molding, and cure it under natural conditions for 1 day until a certain strength is formed, remove the mold, and cut it to obtain a Phase change self-control temperature cement foam insulation board.

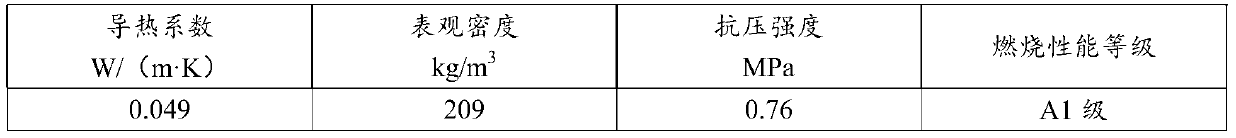

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com