Freeze-resistant concrete and preparation method thereof

A production method and concrete technology, applied in the field of concrete, can solve problems such as strength and bearing capacity decline, concrete damage accumulation, loose cracking, etc., and achieve the effects of enhanced frost resistance, improved service life, and increased air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

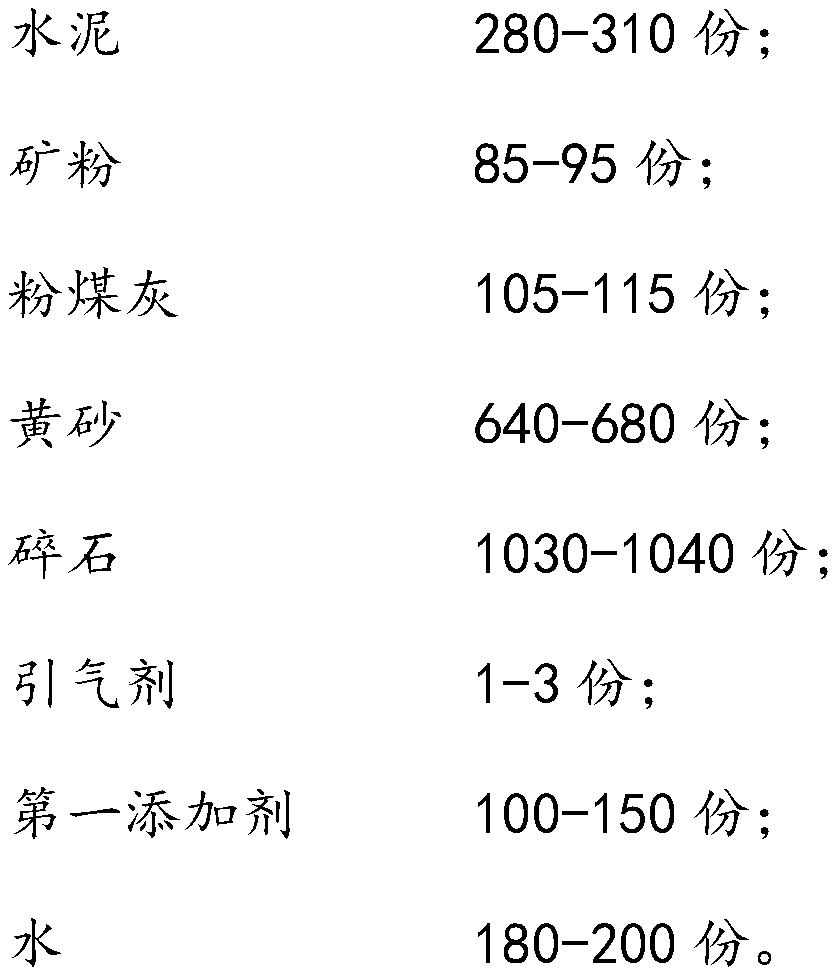

Embodiment 1

[0077] The difference between Examples 13-17 and Example 1 is that the components in the anti-wear agent are listed in the following table by weight percentage.

[0078]

[0079] The difference between Examples 18-23 and Example 1 is that each component in the resist is listed in the following table by weight percentage.

[0080]

[0081]

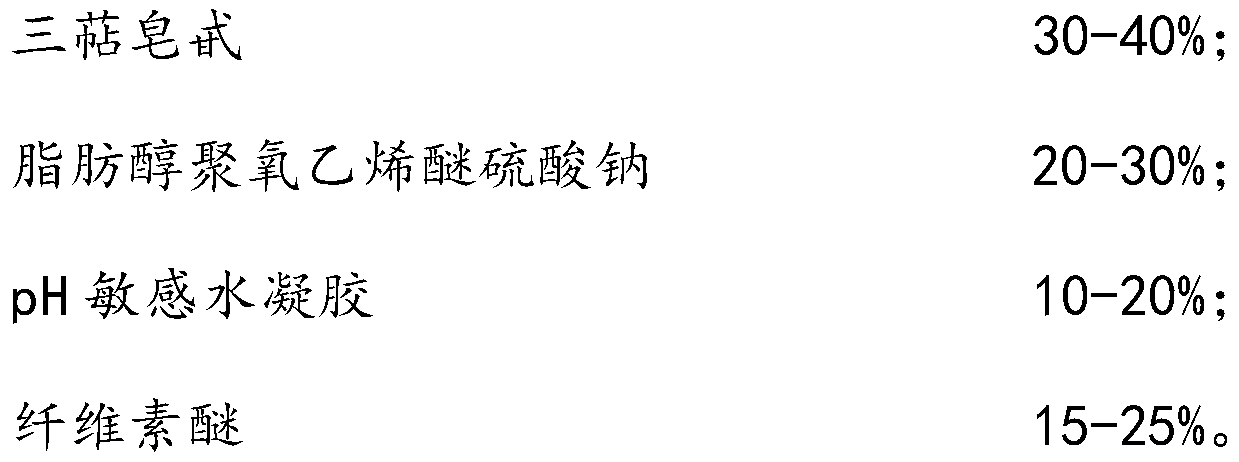

[0082] The difference between Embodiment 24-28 and Embodiment 1 is that each component in the air-entraining agent is calculated as the following table by weight percentage.

[0083]

[0084] The difference between Examples 29-34 and Example 1 is that each component in the first additive is listed in the following table by weight percentage.

[0085]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com