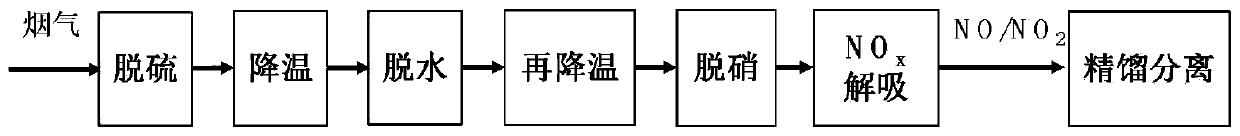

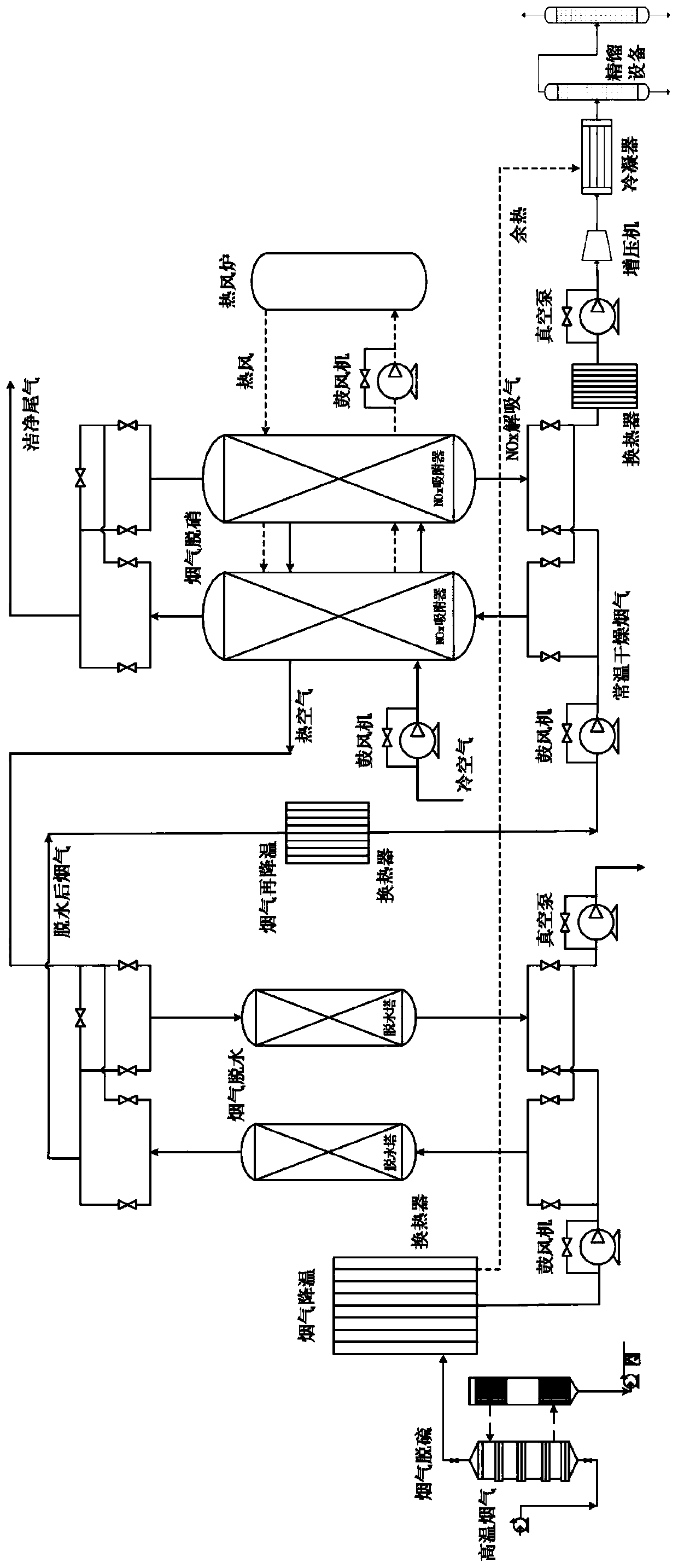

Method and system for adsorbing, purifying, enriching and recycling nitrogen oxides in flue gas

A technology of nitrogen oxides and flue gas, which is applied in the direction of nitrogen oxides/oxyacids, chemical instruments and methods, nitric oxide, etc., can solve the problem of low adsorption capacity, and achieve low adsorbent consumption, low consumption, high matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] In this embodiment, the concentration of NO gas prepared by adopting the above-mentioned method of adsorption, purification, enrichment and recovery of flue gas nitrogen oxides is 10%, and the NO gas concentration is 10%. 2 The liquid concentration is 60%.

Embodiment 2

[0102] A method of adsorption, purification, enrichment and recovery of flue gas nitrogen oxides in this embodiment is basically the same as that of embodiment 1, except that the prepared NO gas concentration is 15%. 2 The liquid concentration is 60%.

Embodiment 3

[0104] A method of adsorption, purification, enrichment and recovery of flue gas nitrogen oxides in this embodiment is basically the same as in embodiment 1, except that the prepared NO gas concentration is 20%, and the NO gas concentration is 20%. 2 The liquid concentration is 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com