Alternating excitation low-temperature heating method for lithium-ion power battery

A technology of power battery and heating method, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of decreased charge and discharge performance, decreased activity of active materials, etc., and achieve the effect of optimal battery self-heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

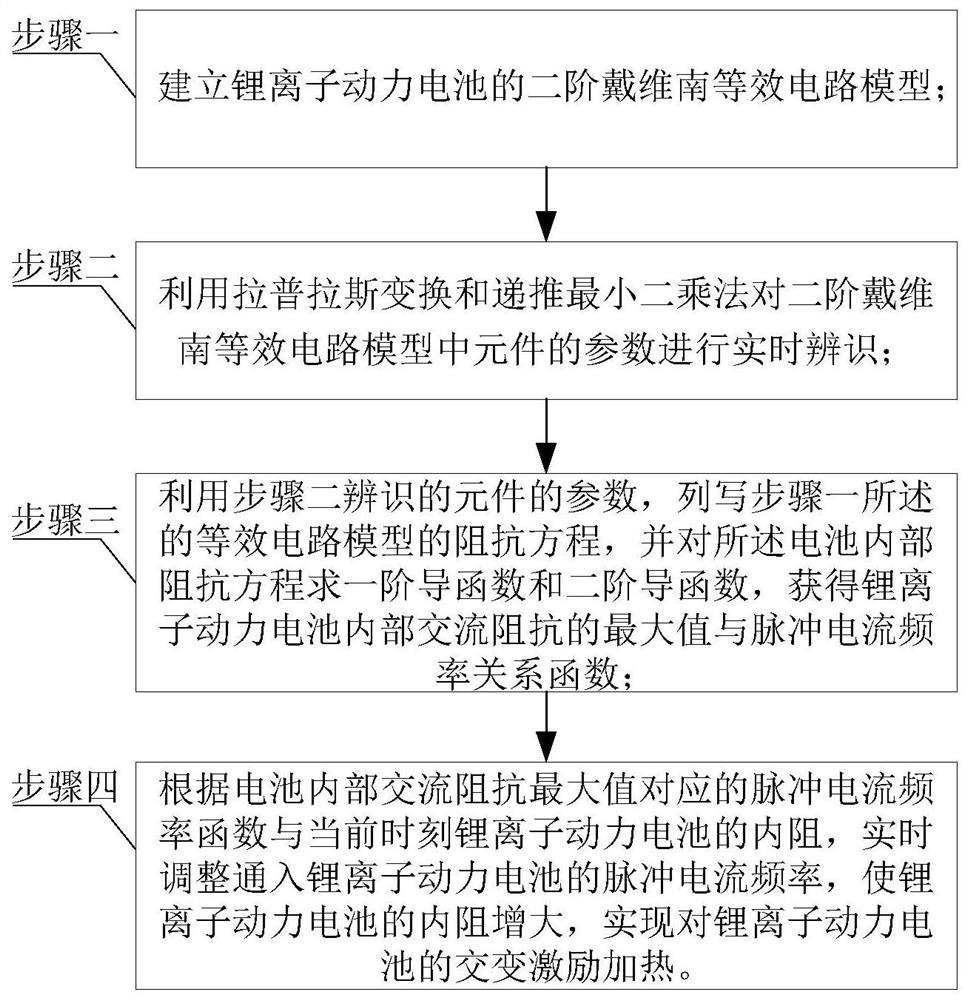

[0014] Specific implementation mode one: the following combination figure 1 Describe this embodiment, a lithium-ion power battery alternating excitation low-temperature heating method described in this embodiment, the specific steps of the method are:

[0015] Step 1: Establish the second-order Thevenin equivalent circuit model of the lithium-ion power battery;

[0016] Step 2: Real-time identification of the parameters of the components in the second-order Thevenin equivalent circuit model by using the Laplace transform and the recursive least squares method;

[0017] Step 3: Using the parameters of the components identified in Step 2, write the impedance equation of the equivalent circuit model described in Step 1, and calculate the first and second derivatives of the internal impedance equation of the battery to obtain the lithium-ion power The function of the relationship between the maximum value of the internal AC impedance of the battery and the frequency of the pulse ...

specific Embodiment approach 2

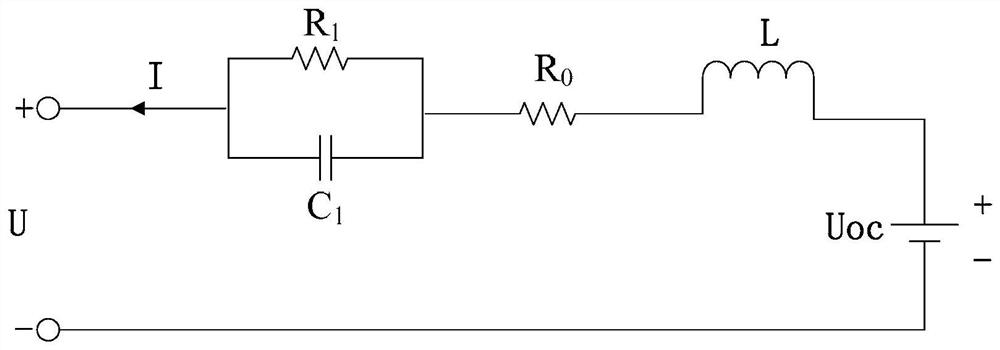

[0020] Specific implementation mode two: the following combination figure 2 Describe this embodiment, this embodiment will further explain the low-temperature heating method of a lithium-ion power battery described in the first embodiment, the second-order Thevenin equivalent circuit model of the lithium-ion power battery described in step 1 includes Polarization internal resistance R 1 , Polarized capacitance C 1 , equivalent internal resistance R 0 , equivalent inductance L and open circuit equivalent voltage source U oc ;

[0021] Polarization internal resistance R 1 One end of the polarized capacitor C 1 One end is connected, and the polarization internal resistance R 1 The end of this terminal is connected to the positive pole of the charging power supply; the polarization internal resistance R 1 The other end of the polarized capacitor C is connected at the same time 1 The other end and the equivalent internal resistance R 0 One end of the equivalent internal r...

specific Embodiment approach 3

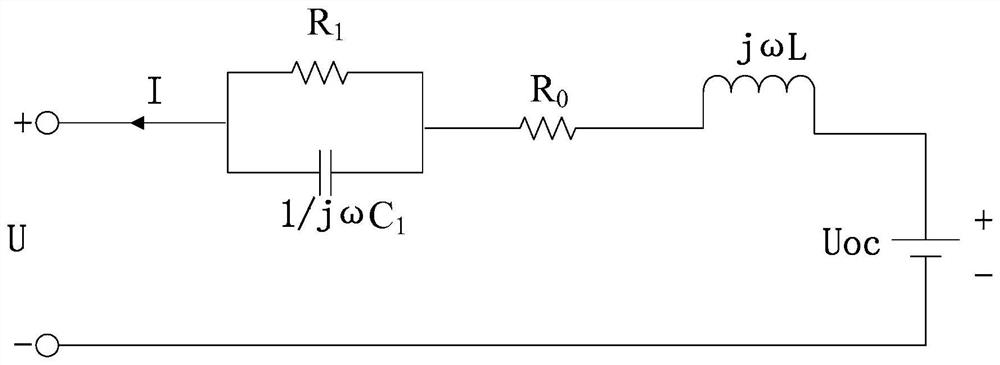

[0022] Specific implementation mode three: the following combination figure 2 Describe this embodiment, this embodiment will further explain the alternating excitation low temperature heating method of a lithium-ion power battery described in the first embodiment, in this embodiment,

[0023] The formula of the second-order Thevenin equivalent circuit model of the lithium-ion power battery described in step 1 is:

[0024]

[0025] Among them, R 0 is the ohmic internal resistance of the lithium-ion power battery, R 1 is the polarization internal resistance of the lithium-ion power battery, C 1 is the polarization capacitance of the lithium-ion power battery, U is the terminal voltage of the lithium-ion power battery, L is the equivalent inductance of the lithium-ion power battery, U oc is the open-circuit equivalent voltage source of the lithium-ion power battery, I is the charging current of the lithium-ion battery, and s is a variable in the frequency domain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com