Self-heating methane tank

A biogas digester and self-heating technology, which is applied in the field of biogas digesters, can solve problems such as increased construction costs of biogas digesters, inability to dissipate biogas normally, corrosion of blocking rod structures, etc., and achieve the effect of simple structure, not easy to agglomerate, and convenient reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

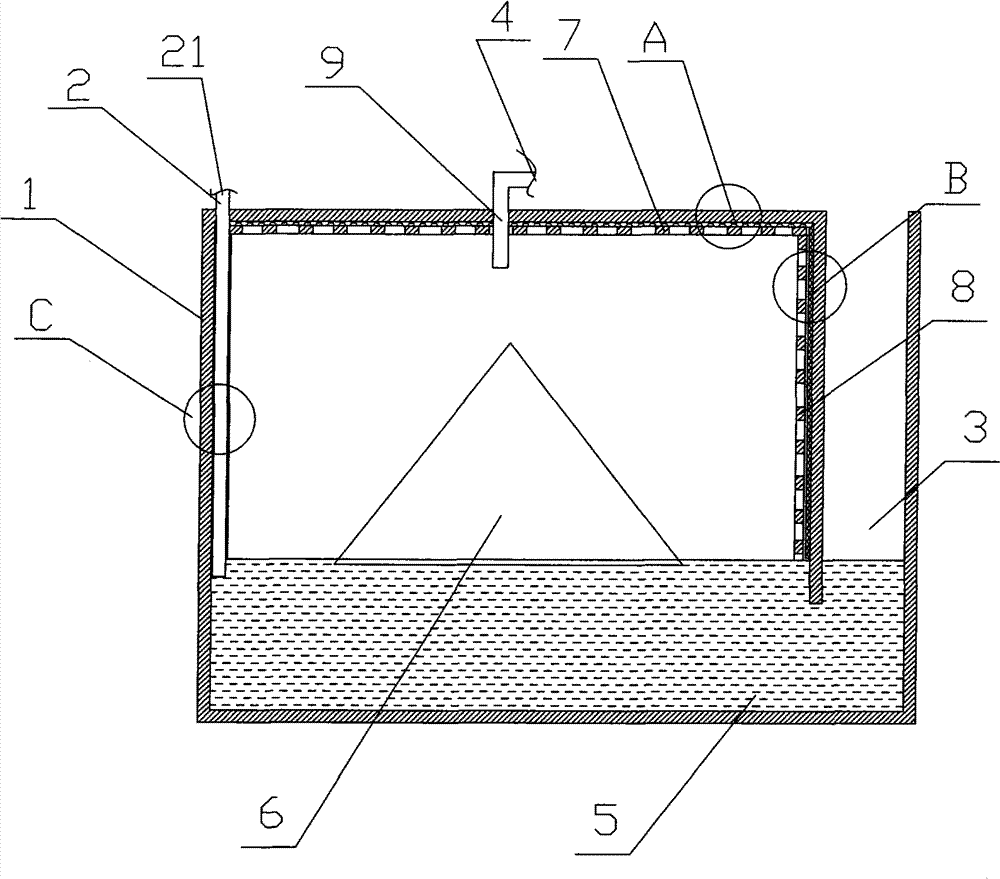

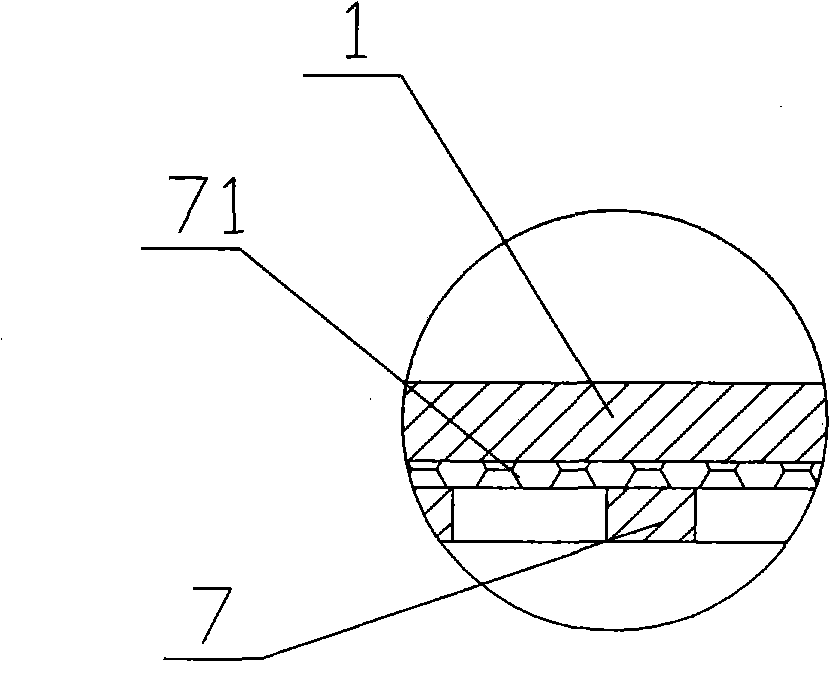

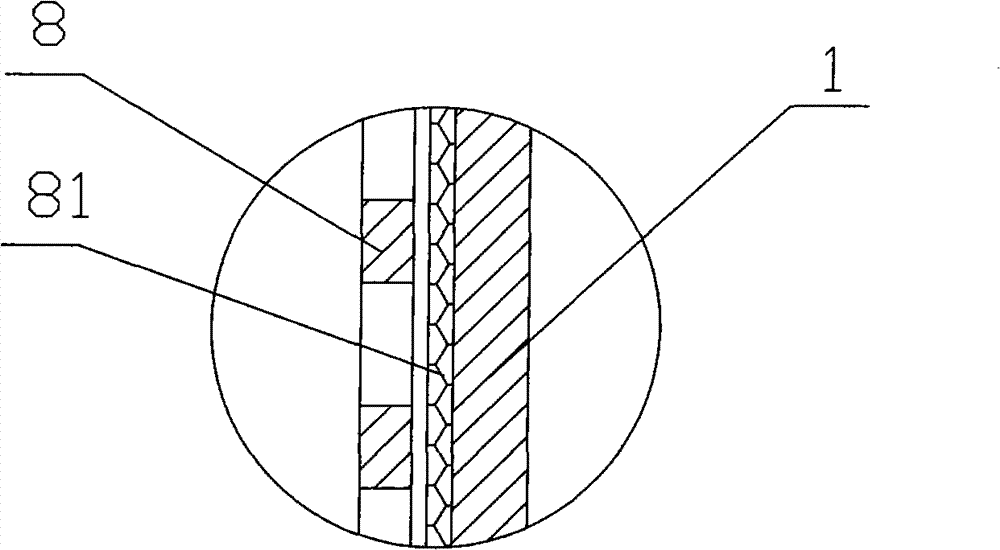

[0019] figure 1 It is a structural schematic diagram of the present invention; figure 2 for figure 1 Enlarged view of part A in the middle; image 3 for figure 1 Enlarged view of part B in the middle; Figure 4 for figure 1 Enlarged view of part C in the middle.

[0020] as the picture shows:

[0021] The self-heating biogas digester of the present embodiment comprises a fermentation chamber 1. The fermentation chamber is provided with a material inlet 2, a material outlet 3 and a biogas outlet 4. The material inlet 2 is sealed and connected with a feed pipe 21. In this embodiment, the feed pipe is made of PVC The material is made and the cross-section is a circle with a diameter of not less than 200mm (certainly, for the convenience of getting materials on the spot, the feed pipe can also be piled up with bricks), and the feed pipe outlet extends into the fermented liquid 5 of the fermentation chamber. Cone 6 is installed horizontally in the fermentation chamber, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com