Preparation method of SnO2/carbon fabric composite material for sodium ion battery negative electrode

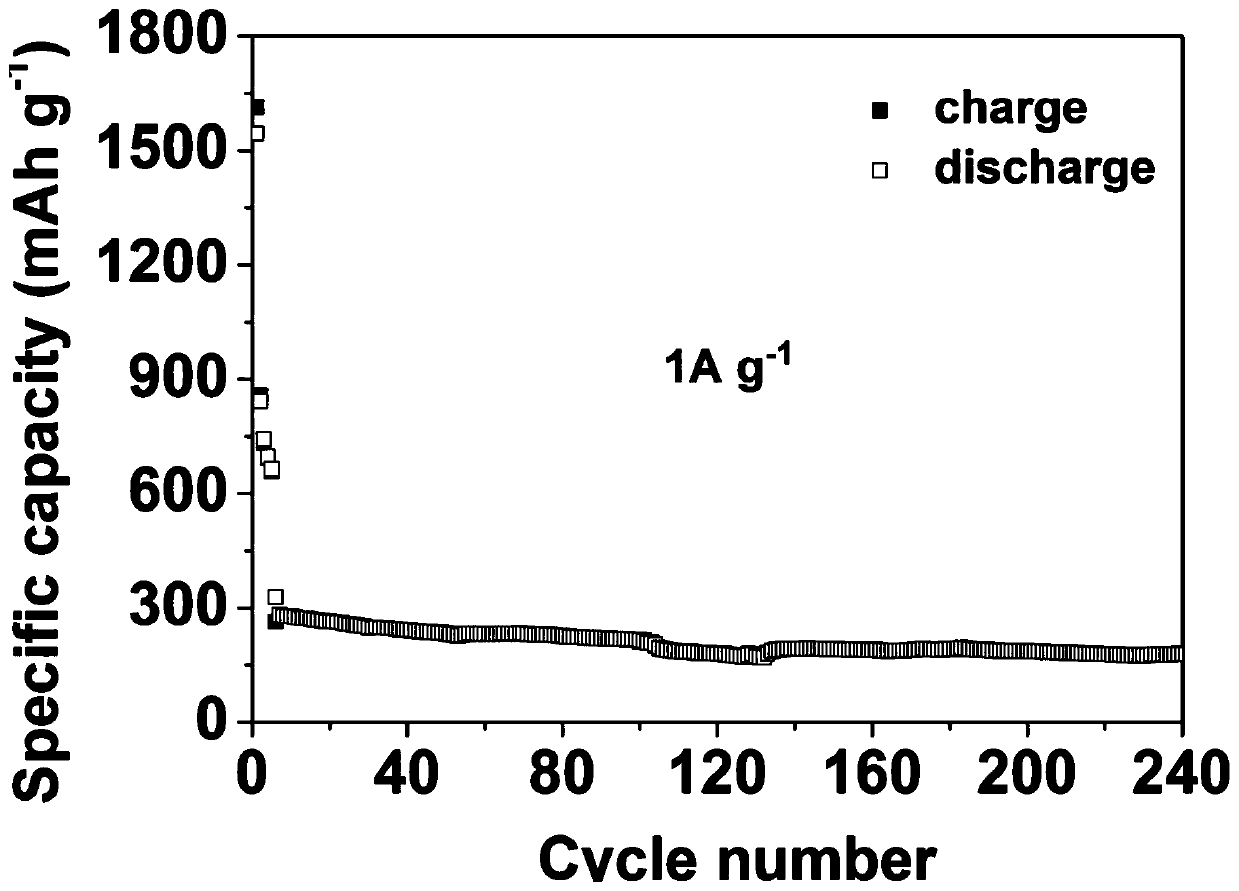

A sodium-ion battery and composite material technology, which is applied in the field of preparation of SnO2/carbon cloth composite materials for the negative electrode of sodium-ion batteries, can solve the problems of reducing battery efficiency and cycle performance, material powdering and falling off, and affecting the practical application of materials. High repeatability, short cycle, significant scientific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Ultrasonic cleaning of 3×3 cm hydrophilic carbon cloth in ethanol and deionized water for 3 h each, and then placing the carbon in a muffle furnace from room temperature to 480 °C at a heating rate of 10 °C / min for air oxidation Treat for 10 minutes to increase the activity of the carbon cloth surface and make it easier to attach metal without affecting the mechanical properties of the carbon cloth;

[0026] 2) 0.524g of SnCl 2 2H 2 O was dissolved in 25mL of deionized water and 25ml of ethylene glycol mixed solvent to obtain solution A1, then ultrasonic treatment with ultrasonic power of 100W for 10min, stirring evenly to obtain a uniform mixed solution;

[0027] 3) Transfer the mixed solution obtained in step 2) and the pretreated carbon cloth to a polytetrafluoroethylene hydrothermal kettle, control the filling degree to 30%, and then place the polytetrafluoroethylene hydrothermal kettle in a homogeneous reaction In a device (Yantai Keli Chemical Equipment Co., ...

Embodiment 2

[0030] 1) Ultrasonic cleaning of a 5×5 cm hydrophilic carbon cloth in ethanol and deionized water for 6 h each, and then placing the carbon in a muffle furnace from room temperature to 400 °C at a heating rate of 10 °C / min for air oxidation Treat for 10 minutes to increase the activity of the carbon cloth surface and make it easier to attach metal without affecting the mechanical properties of the carbon cloth;

[0031] 2) 0.524g of SnCl 2 2H 2 O was dissolved in 40mL of deionized water and 10ml of ethylene glycol mixed solvent to obtain solution A1, then ultrasonically treated with ultrasonic power of 100W for 10min, and stirred evenly to obtain a uniform mixed solution;

[0032] 3) Transfer the mixed solution obtained in step 2) and the pretreated carbon cloth to a polytetrafluoroethylene hydrothermal kettle, control the filling degree to 50%, and then place the polytetrafluoroethylene hydrothermal kettle in a homogeneous reaction In the apparatus (Yantai Keli Chemical Equ...

Embodiment 3

[0038] 1) Ultrasonic cleaning of 4×4 cm hydrophilic carbon cloth in ethanol and deionized water for 4 h twice, and then the carbon was placed in a muffle furnace from room temperature to 360 °C at a heating rate of 10 °C / min for air oxidation Treat for 5 minutes to increase the activity of the carbon cloth surface and make it easier to attach metal without affecting the mechanical properties of the carbon cloth;

[0039] 2) 1.08g of SnCl 2 2H 2 O was dissolved in 35mL of deionized water and 15ml of ethylene glycol mixed solvent to obtain solution A1, then ultrasonic treatment with ultrasonic power of 100W for 20min, stirring evenly to obtain a uniform mixed solution;

[0040] 3) Transfer the mixed solution obtained in step 2) and the pretreated carbon cloth to a polytetrafluoroethylene hydrothermal kettle, control the filling degree to 50%, and then place the polytetrafluoroethylene hydrothermal kettle in a homogeneous reaction In the apparatus (Yantai Keli Chemical Equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com