High-temperature power cable for cloud rail transit

A power cable and transportation technology, applied in the field of high-temperature power cables for cloud rail transit, can solve the problems of low power supply reliability, high insulation resistance, large space occupation, etc., to improve reliability and safety, improve temperature resistance level, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

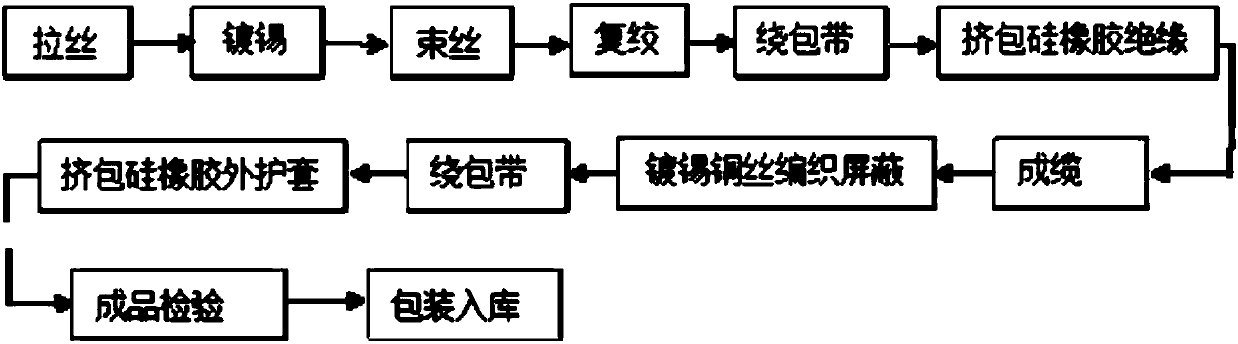

Method used

Image

Examples

Embodiment 1~3

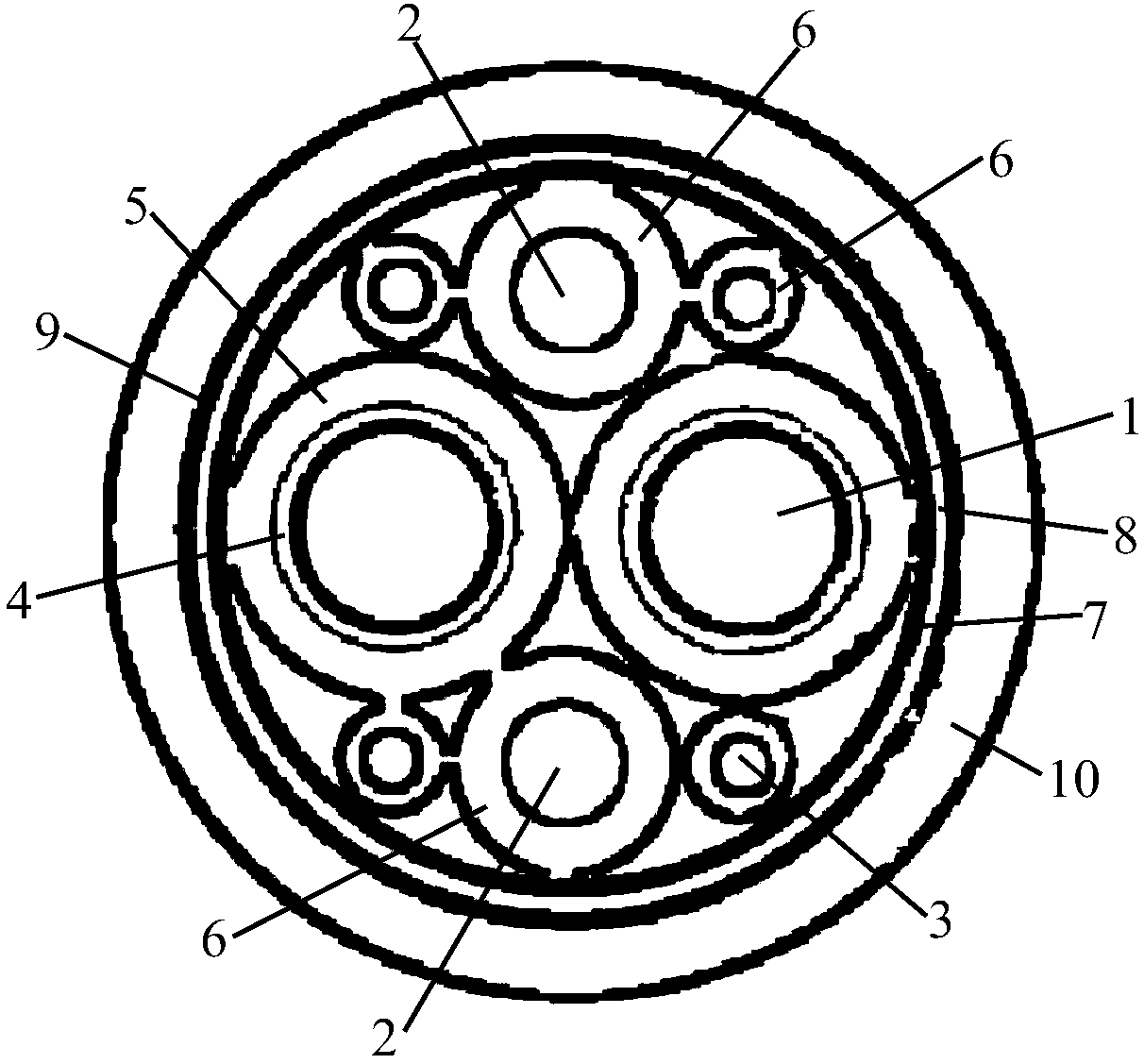

[0019] Embodiments 1 to 3: A high-temperature power cable for cloud rail transit, including 2 five types of copper conductors 1, 2 large filled polyester ropes 2 and 4 small filled polyester ropes 3, the outer surface of the five types of copper conductors 1 Wrapped with a first high-temperature-resistant polyester belt 4, the outer surface of the first high-temperature-resistant polyester belt 4 is covered with a first silicone rubber insulating layer 5, and the outer surfaces of the large filled polyester rope 2 and the small filled polyester rope 3 are both coated with a second silicone rubber insulating layer 6;

[0020] Two layers of the second high-temperature-resistant polyester tape 7 are overlapped and wrapped on the outer surface of two five-category copper conductors 1, 2 large filled polyester ropes 2 and 4 small filled polyester ropes 3, and a tinned copper wire braid layer 8 is wrapped On the outer surface of the 2 layers of the second high temperature resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com