Biomass particle combustion furnace

A biomass particle and combustion furnace technology, which is applied in the direction of combustion method, combustion equipment, solid fuel combustion, etc., can solve the problems of insufficient combustion process, uneven combustion of fuel, low combustion efficiency and combustion power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

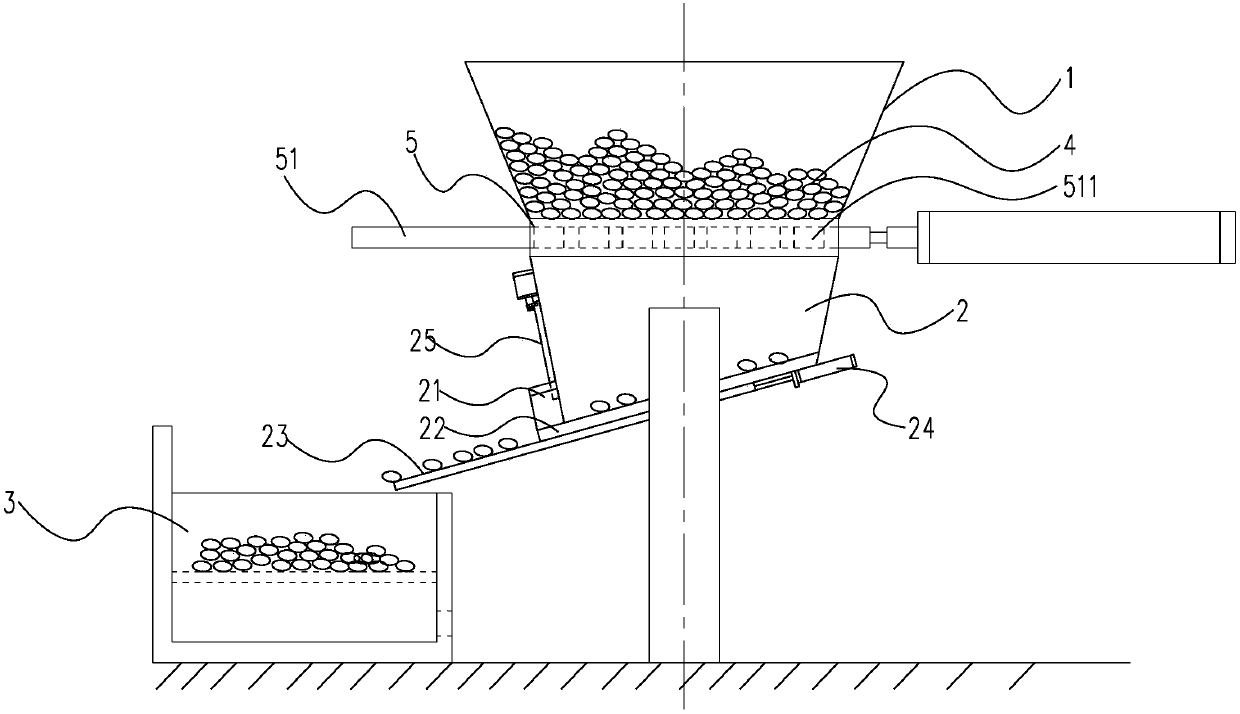

[0014] The present invention as figure 1 As shown, it includes a waiting bin 1, a feeding bin 2 and a combustion bin 3. The waiting bin 1 is in a V-shaped structure and is fixedly connected to the top of the feeding bin 2, and the burning bin 3 is fixedly connected to the feeding bin. Below the bin 2, the feeding bin 2 is provided with a discharge port 21 on the side close to the combustion bin 3;

[0015] The bottom plate 22 of the feeding bin 2 is inclined downward, and the biomass particles 4 move toward the combustion bin 3 through the inclined bottom plate 22; an adapted feeding plate 23 is provided below the bottom plate 22, and the feeding The plate 23 is moved along the inclined direction of the bottom plate 22 by the linear drive mechanism 24 .

[0016] The biomass particles 4 entering the feeding bin 2 are evenly distributed into the combustion bin 3 through the moving feeding plate 23; Vibration generated by rapping will evenly distribute the biomass particles 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com