Collagen calcium peptide powder and preparation method thereof

A technology of bone collagen powder and collagen, which is applied in protein food processing, protein food ingredients, food forming, etc., can solve the problem of unreasonable ratio of collagen peptide and calcium, poor absorption rate of human body, and easy formation of powder particles. Block and other problems, to achieve the effect of not easy to agglomerate, refreshing taste, and no loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

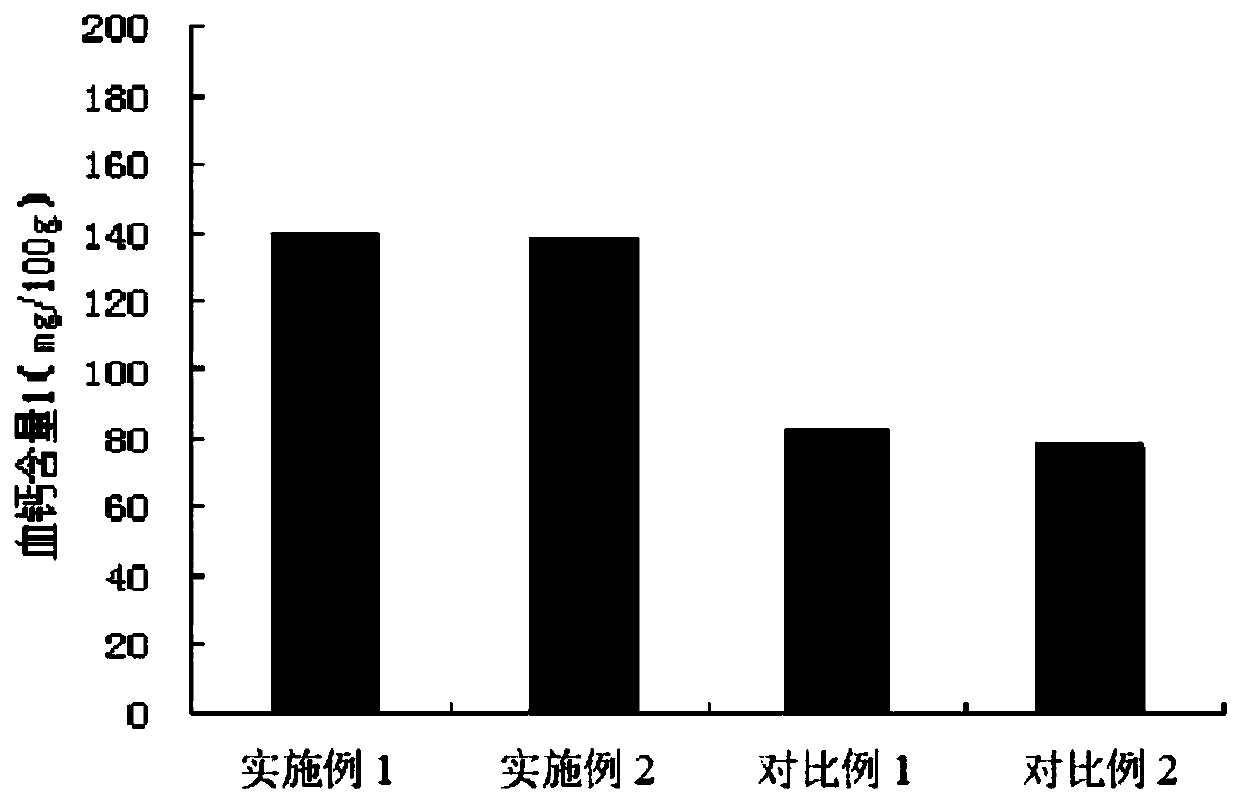

Embodiment 1

[0034] Weigh the raw materials of each component with appropriate quality according to the mass percentage, 69% of bone collagen powder, 5% of lemon powder, 7% of calcium lactate, 1% of casein phosphopeptide, 1% of xylitol powder, 0.8% of sucralose, 1.2% citric acid monohydrate powder, 4% resistant dextrin, 10% maltodextrin, 0.5% xanthan gum, and 0.5% lemon essence, and sieve them into 40 mesh respectively, and then put the raw materials into the mixer and mix them evenly to obtain Collagen Calcium Peptide Powder.

Embodiment 2

[0036] Weigh the raw materials of each component with appropriate quality according to the mass percentage, 66% of bone collagen powder, 6% of lemon powder, 6% of calcium lactate, 1% of casein phosphopeptide, 2% of xylitol powder, 1% of sucralose, 1% citric acid monohydrate powder, 4% resistant dextrin, 11% maltodextrin, 1% xanthan gum, 1% lemon flavor, and then put into a mixer and mix evenly to obtain collagen calcium peptide powder.

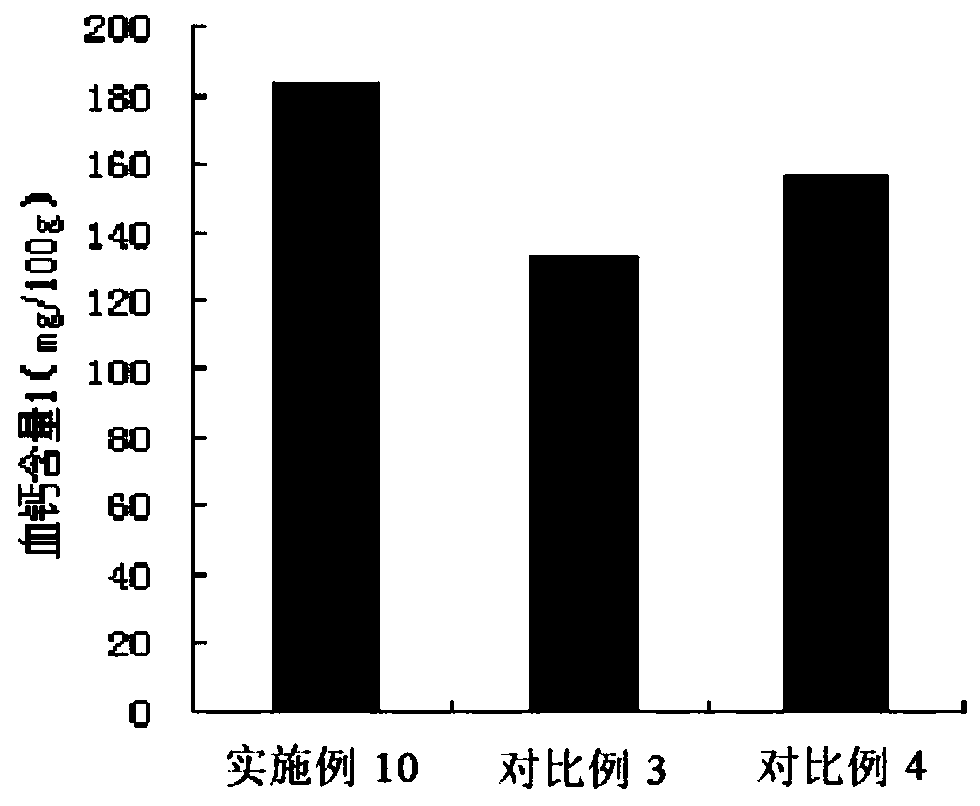

Embodiment 3

[0045] Collagen calcium peptide powder is prepared by the following steps:

[0046] S1. Weigh each component raw material with appropriate quality according to the mass percentage, bone collagen powder 69%, lemon powder 5%, calcium lactate 7%, casein phosphopeptide 1%, xylitol powder 1%, sucralose 0.8 %, 1.2% citric acid monohydrate powder, 4% resistant dextrin, 10% maltodextrin, 0.5% xanthan gum, 0.5% lemon flavor, then bone collagen powder, resistant dextrin, calcium lactate, malt Put the dextrin in the granulator in order, set the air inlet temperature to 130°C, turn on the fan to start heating the mixed material, the fan frequency is 16Hz, when the temperature of the mixed material reaches 58°C, spray pure water as a binder to granulate, After the spraying of pure water is completed, continue to boil and dry until the water content is below 3%, stop drying, stop the fan, then clean the dust, stop the spray gun aerosol, discharge the material, and obtain the granulated mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com