Ultrathin metal based transparent conductive film

A transparent conductive film, ultra-thin metal technology, applied in conductive layers on insulating carriers, metal material coating process, ion implantation plating, etc., can solve the problem of insufficient film adhesion, poor thermal stability, and poor oxidation resistance. and other problems, to achieve the effect of excellent anti-scratch stability, improved humidity and heat stability, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

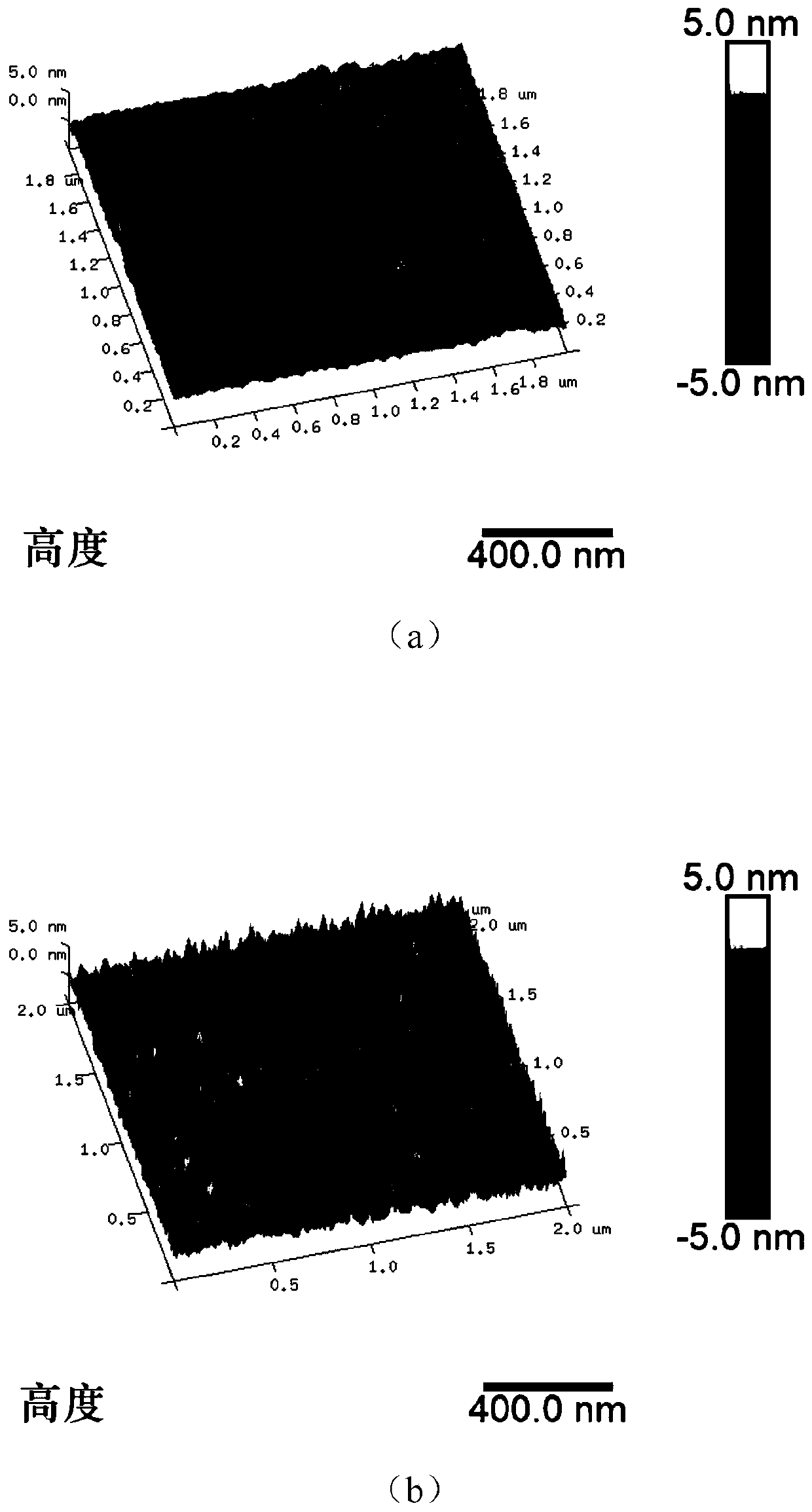

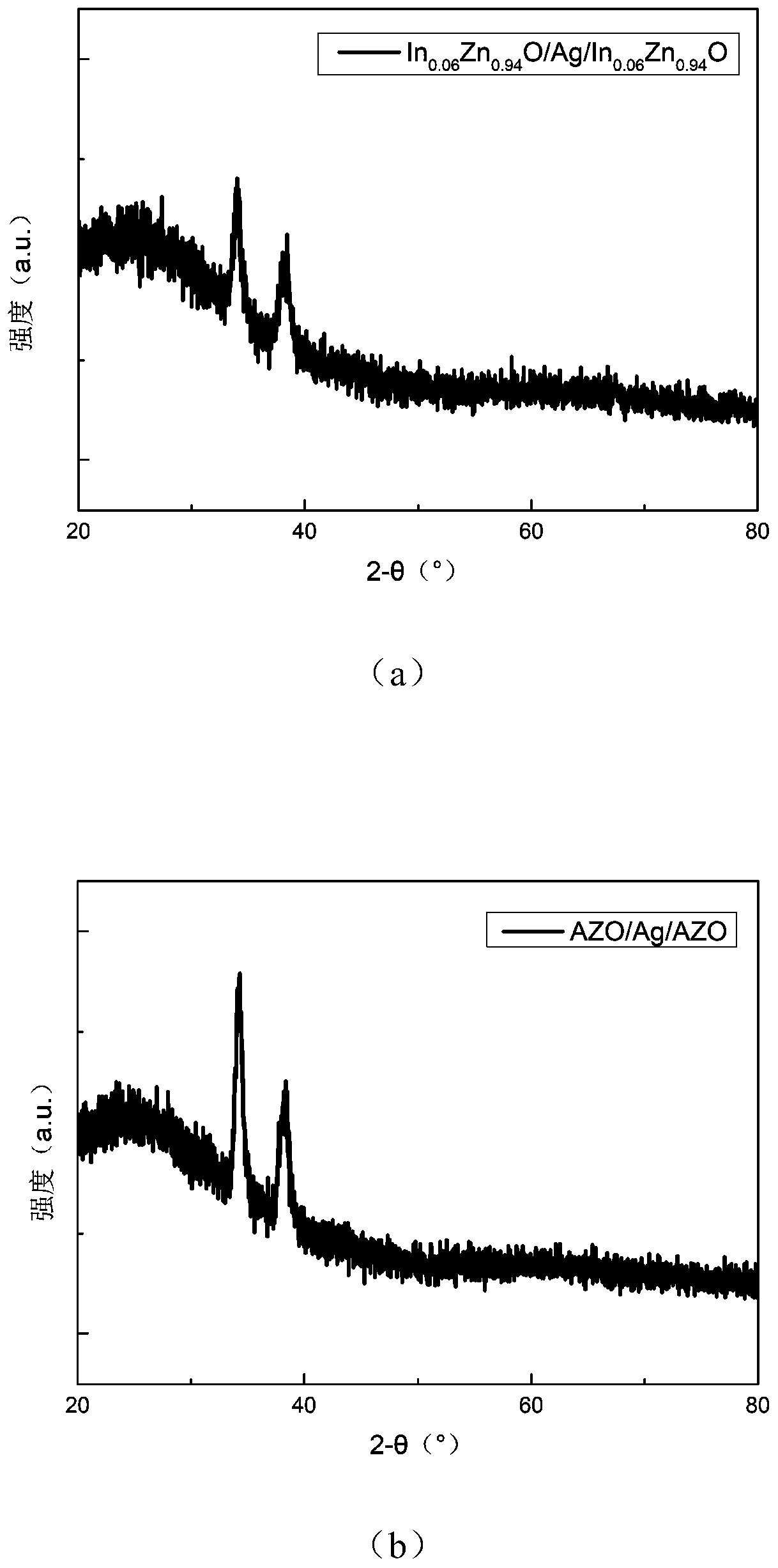

[0022] The ultra-thin metal-based transparent conductive film of embodiment 1 includes a bottom dielectric layer, an ultra-thin metal layer and a top dielectric layer arranged in sequence from bottom to top, the ultra-thin metal layer is a silver layer, the top dielectric layer and the bottom The chemical composition of the dielectric layer is In x Zn 1-x O, where In is the doping element, and In is In 2 o 3 Incorporated into ZnO in the form of In x Zn 1-x O, x = 0.06.

[0023] In embodiment 1, the thickness of the bottom dielectric layer and the top dielectric layer are both 40 nm, and the thickness of the ultra-thin metal layer is 10 nm.

[0024] In Example 1, both the bottom dielectric layer and the top dielectric layer are made of In-doped 2 o 3 The ZnO target material is deposited by radio frequency magnetron sputtering at room temperature. The specific process is: when the background vacuum degree is less than 6.8×10 -4 In the state of Pa, radio frequency magnetr...

Embodiment 2

[0031] The ultra-thin metal-based transparent conductive film of embodiment 2 includes a bottom dielectric layer, an ultra-thin metal layer and a top dielectric layer arranged in sequence from bottom to top, the ultra-thin metal layer is a silver layer, the top dielectric layer and the bottom The chemical composition of the dielectric layer is Mg x Zn 1-x O, where Mg is a doping element, and Mg is doped into ZnO in the form of MgO to obtain Mg x Zn 1-x 0,x=0.24.

[0032] In embodiment 2, the thickness of the bottom dielectric layer and the top dielectric layer are both 40 nm; the thickness of the ultra-thin metal layer is 10 nm.

[0033] In Example 2, both the bottom dielectric layer and the top dielectric layer are obtained by radio frequency magnetron sputtering deposition of MgO-doped ZnO targets at room temperature. The specific process is as follows: when the background vacuum degree is less than 6.8×10 -4 In the state of Pa, radio frequency magnetron sputtering film ...

Embodiment 3

[0037] The ultra-thin metal-based transparent conductive film of embodiment 3 includes a bottom dielectric layer, an ultra-thin metal layer and a top dielectric layer arranged in sequence from bottom to top, the ultra-thin metal layer is a silver layer, the top dielectric layer and the bottom The chemical composition of the dielectric layer is Gd x Zn 1-x O, where Gd is a doping element, and Gd is doped into ZnO in the form of GdO to obtain Gd x Zn 1-x O, x=0.01.

[0038] In embodiment 3, the thickness of the bottom dielectric layer and the top dielectric layer are both 45nm; the thickness of the ultra-thin metal layer is 8nm.

[0039] In embodiment 3, both the bottom dielectric layer and the top dielectric layer are made of Gd-doped 2 o 3 The ZnO target material is deposited by radio frequency magnetron sputtering at room temperature. The specific process is: when the background vacuum degree is less than 6.8×10 -4 In the state of Pa, radio frequency magnetron sputterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com