System and method for comprehensively utilizing gasification ash

A kind of ash and gasification device technology, which is applied in the field of gasification ash comprehensive utilization system, can solve the problems of inability to achieve reduction and resource utilization, limit reuse methods, and heat can not be used, etc., to achieve good economy and environmental protection Benefits, improving the overall heat utilization efficiency, reducing the difficulty of processing and the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

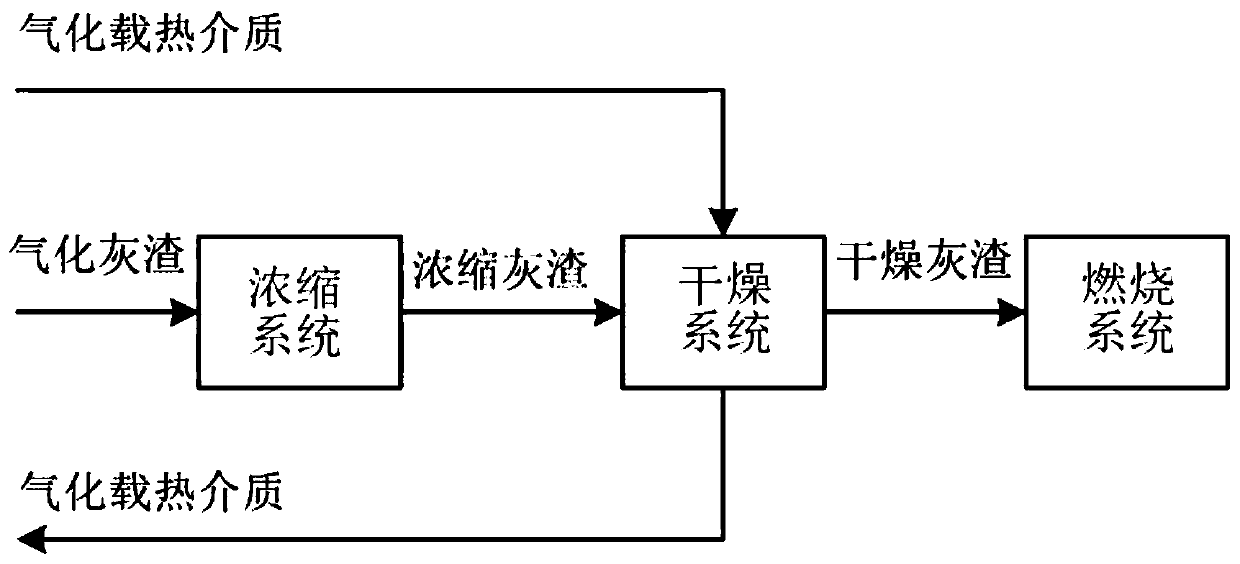

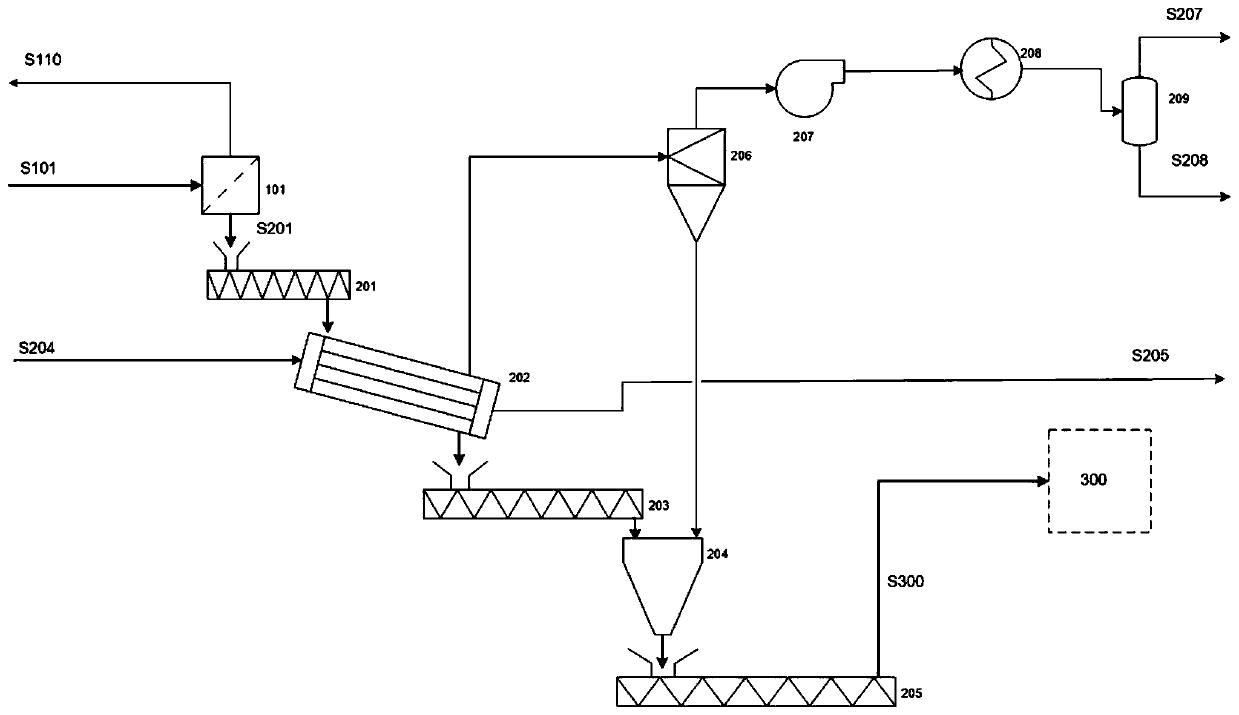

[0050] like figure 2 As shown, the gasification ash comprehensive utilization system provided by the embodiment of the present invention includes a concentration system, a drying system and a combustion system.

[0051] The concentration system device is mainly a filter device, and the technical requirements of this embodiment can be met by vacuum filtration, centrifugal filtration or plate-and-frame filtration and other filtration methods. The gasification fine slag (slag) S101 discharged from the gasification device enters the filter device 101 and forms concentrated ash 201 after preliminary dehydration, and the concentrated ash 201 enters the drying system through the feeder 201; the moisture removed in the filter device 101 is used as The filtrate S110 is returned to the gasification device for recycling.

[0052]The drying system includes a dryer, a filter, an air induction device, a condenser and its separator, a storage device and a feed discharge device. In this em...

Embodiment 2

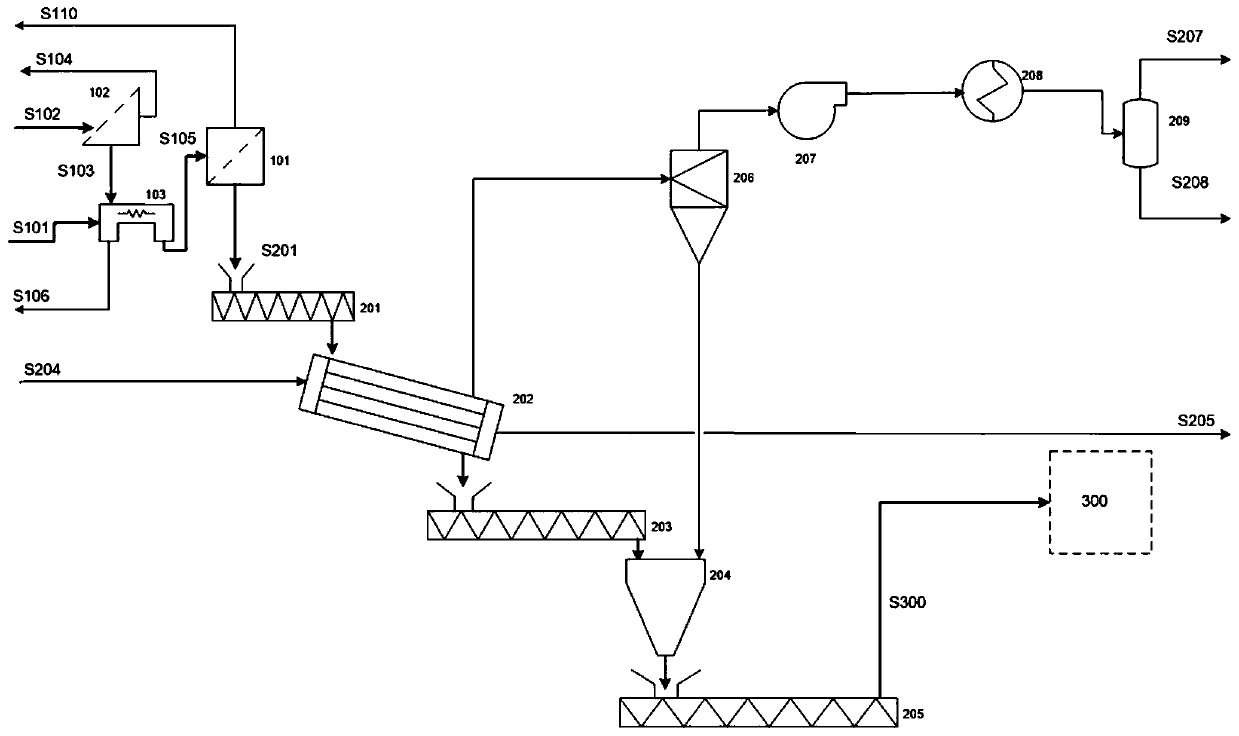

[0065] like image 3 As shown, the gasification ash comprehensive utilization system provided by the embodiment of the present invention includes a concentration system, a drying system and a combustion system. Compared with Embodiment 1, the concentration system of this embodiment includes a screening and washing device, a flotation device and a filtering device. The drying system, combustion system and flow process are all the same as those in Embodiment 1, and will not be repeated here.

[0066] The concentration system mainly includes a screening washing device 102 , a flotation device 103 and a filtering device 101 . The coarse slag S102 from the gasification device passes through the screening and washing device 102 to obtain the sieved fine slag S103 with a smaller particle size and higher carbon content, and the sieved coarse slag S104 with a larger particle size and lower carbon content Screening coarse slag S104 is discharged from the comprehensive utilization syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com