Silicone rubber for heat-conduction silicone sheet and preparation method of silicone rubber

A technology of silicone rubber and heat-conducting silicon, which is applied in the field of silicone rubber for heat-conducting silicone skin and its preparation, can solve the problem of high vulcanization temperature, and achieve the effects of no pollution to the mold, excellent flame retardant performance, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

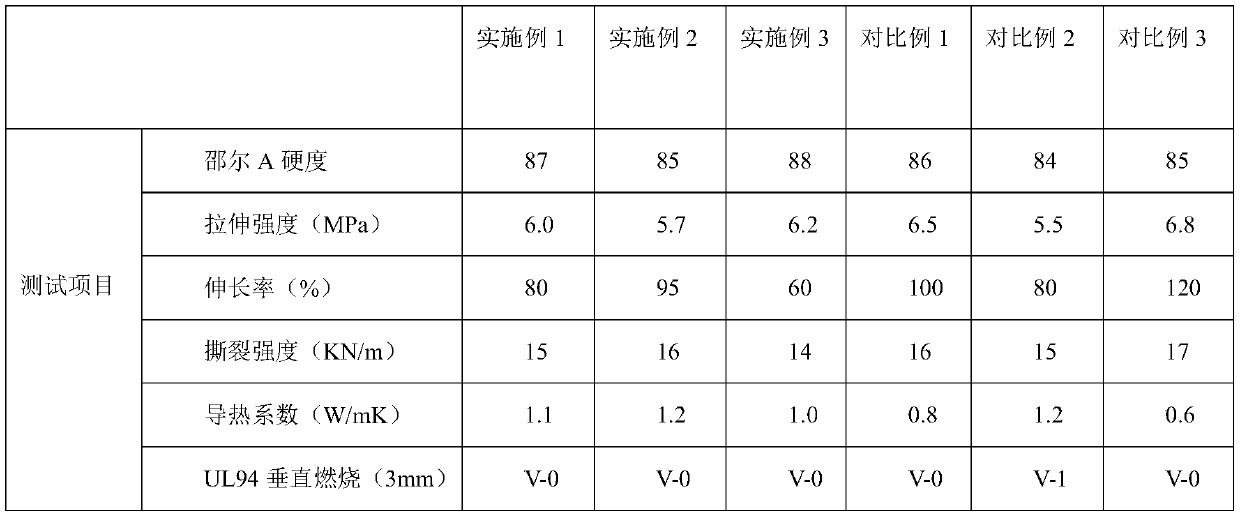

Examples

Embodiment 1

[0060] The components in parts by mass are as follows: 5 parts of raw methyl vinyl silicone rubber with a molecular weight of 500,000 and a vinyl content of 3.0%, and raw methyl vinyl silicone rubber with a molecular weight of 650,000 and a vinyl content of 0.05%. 50 parts, 45 parts of methyl vinyl silicone rubber raw rubber with a molecular weight of 600,000 and a vinyl content of 0.22%, and a BET method specific area of 200m 2 25 parts / g of fumed white carbon black, the specific area is 65m 2 35 parts of superconducting acetylene carbon black per gram, 125 parts of silicon carbide with a particle size of 18 μm, 100 parts of silicon carbide with a particle size of 6.5 μm, 4.0 parts of hydroxy silicone oil with a viscosity of 25 mPa.s, 0.3 parts of zinc stearate, ethylene 1.5 parts of trimethoxysilane, 1.0 parts of hydrogen-containing silicone oil with an active hydrogen mass fraction of 0.7%, and a mass fraction of platinum of 1.0×10 -5 Alcohol-modified chloroplatinic acid...

Embodiment 2

[0067] The components in parts by mass are as follows: 5 parts of methyl vinyl silicone rubber raw rubber with a molecular weight of 450,000 and a vinyl content of 2.0%, methyl vinyl silicone rubber raw rubber with a molecular weight of 600,000 and a vinyl content of 0.08% 50 parts, 45 parts of methyl vinyl silicone rubber raw rubber with a molecular weight of 550,000 and a vinyl content of 0.3%, and a BET method specific area of 150m 2 20 parts / g of fumed white carbon black, the specific area is 65m 2 40 parts per gram of superconducting acetylene carbon black, 125 parts of silicon carbide with a particle size of 15 μm, 125 parts of silicon carbide with a particle size of 10 μm, 6.0 parts of hydroxyl silicone oil with a viscosity of 28 mPa.s, 0.5 parts of zinc stearate, vinyl 2.0 parts of trimethoxysilane, 0.5 parts of hydrogen-containing silicone oil with a mass fraction of active hydrogen of 0.8%, and a mass fraction of platinum of 1.0×10 -4 Alcohol-modified chloroplatin...

Embodiment 3

[0070] The components in parts by mass are as follows: 5 parts of raw methyl vinyl silicone rubber with a molecular weight of 400,000 and a vinyl content of 4.0%, and raw methyl vinyl silicone rubber with a molecular weight of 700,000 and a vinyl content of 0.03%. 50 parts, 45 parts of methyl vinyl silicone rubber raw rubber with a molecular weight of 500,000 and a vinyl content of 0.2%, and a BET method specific area of 380m 2 30 parts / g of fumed silica, the specific area is 65m 240 parts per gram of superconducting acetylene carbon black, 100 parts of silicon carbide with a particle size of 15 μm, 100 parts of silicon carbide with a particle size of 10 μm, 2.0 parts of hydroxyl silicone oil with a viscosity of 35 mPa.s, 0.4 parts of zinc stearate, vinyl 1.0 parts of trimethoxysilane, 0.8 parts of hydrogen-containing silicone oil with an active hydrogen mass fraction of 0.5%, and a mass fraction of platinum of 1.0×10 -6 Alcohol-modified chloroplatinic acid catalyst 1.0 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com