Preparation method of nano molybdenum oxide hybrid magnesium hydroxide flame retardant

A magnesium hydroxide and nano-oxidation technology, applied in the directions of molybdenum oxide/molybdenum hydroxide, magnesium hydroxide, nanotechnology, etc., can solve the problems of high price, large amount of addition, easy environmental pollution, etc., to improve smoke suppression performance, The effect of improving flame retardant performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

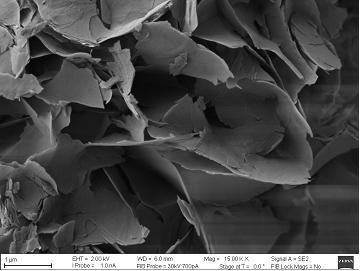

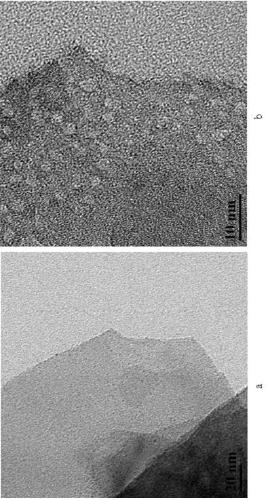

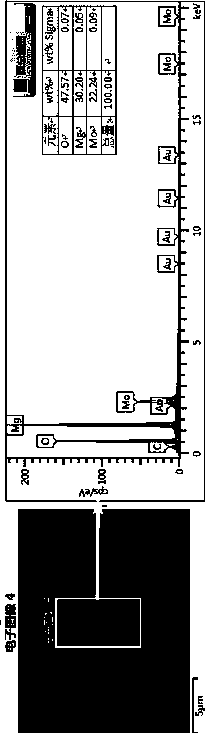

Image

Examples

Embodiment 1

[0037] Example 1 A method for preparing a nanomolybdenum oxide hybrid magnesium hydroxide flame retardant, comprising the following steps:

[0038] ⑴Weigh 3.05g MgCl 2 ·6H 2 O, add water to make 30mL, concentration is 0.5mol / L magnesium chloride solution;

[0039] (2) Add 1.20 g of solid NaOH to the magnesium chloride solution, stir to dissolve it, and obtain magnesium hydroxide slurry;

[0040] (3) Weigh 2.65g (NH 4 ) 6 Mo 7 o 24 4H 2 O, add water and be mixed with 30mL, concentration is the ammonium molybdate solution of 0.07mol / L;

[0041] (4) Under stirring conditions, the molar ratio of Mg and Mo is 1:1, ammonium molybdate solution is added in the magnesium hydroxide slurry to obtain a mixed slurry;

[0042] (5) Transfer the mixed slurry to a 100mL hydrothermal reactor with a filling degree of 60%, place it in a homogeneous reactor, and react at 160°C for 10 hours. After the reaction, cool naturally to room temperature to obtain a white suspension;

[0043] (6) T...

Embodiment 2

[0045] Example 2 A method for preparing a nanomolybdenum oxide hybrid magnesium hydroxide flame retardant, comprising the following steps:

[0046] ⑴Weigh 0.61g MgCl 2 ·6H 2 O, add water to prepare a 30mL magnesium chloride solution with a concentration of 0.1mol / L;

[0047] (2) Add 0.30 g of solid NaOH to the magnesium chloride solution, stir to dissolve it, and obtain magnesium hydroxide slurry;

[0048] (3) Weigh 0.53g (NH 4 ) 6 Mo 7 o 24 4H 2 O, add water and be mixed with 30mL, concentration is the ammonium molybdate solution of 0.014mol / L;

[0049] (4) Under stirring conditions, the molar ratio of Mg and Mo is 1:1, ammonium molybdate solution is added in the magnesium hydroxide slurry to obtain a mixed slurry;

[0050] (5) Transfer the mixed slurry to a 100mL hydrothermal reactor with a filling degree of 60%, place it in a homogeneous reactor, and react at 160°C for 10 hours. After the reaction, cool naturally to room temperature to obtain a white suspension;

...

Embodiment 3

[0052] Example 3 A method for preparing a nanomolybdenum oxide hybrid magnesium hydroxide flame retardant, comprising the following steps:

[0053] ⑴Weigh 6.10g MgCl 2 ·6H 2 O, add water to prepare a 30mL magnesium chloride solution with a concentration of 1.0mol / L;

[0054] (2) Add 1.20 g of solid NaOH to the magnesium chloride solution, stir to dissolve it, and obtain magnesium hydroxide slurry;

[0055] (3) Weigh 5.30g (NH 4 ) 6 Mo 7 o 24 4H 2 O, add water and be mixed with 30mL, concentration is the ammonium molybdate solution of 0.14mol / L;

[0056] (4) Under stirring conditions, the molar ratio of Mg and Mo is 1:1, ammonium molybdate solution is added in the magnesium hydroxide slurry to obtain a mixed slurry;

[0057] (5) Transfer the mixed slurry to a 100mL hydrothermal reactor with a filling degree of 60%, place it in a homogeneous reactor, and react at 160°C for 10 hours. After the reaction, cool naturally to room temperature to obtain a white suspension;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com