Forging method and device capable of increasing flaw detection level

A horizontal, forging heating technology, applied in the field of material processing, to achieve the effect of improving the level of flaw detection, high durable strength, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] 1. Pre-forging production:

[0041] Heating the bar stock, when the heating temperature reaches the preset head fire temperature range, keep it warm for 200min, adopt the head fire die to forge the heated bar stock, and obtain the pre-forging.

[0042] Preferably, the head fire temperature range is 1095°-1105°.

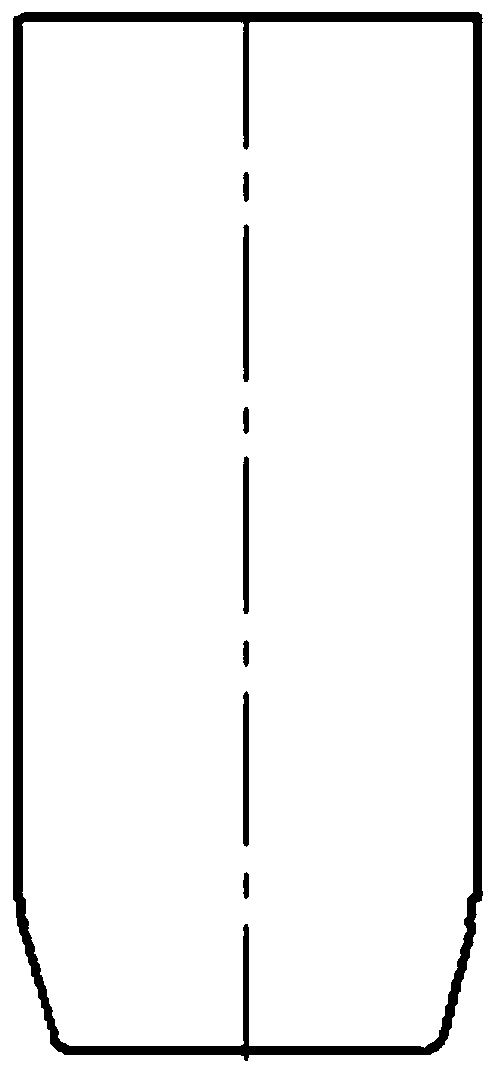

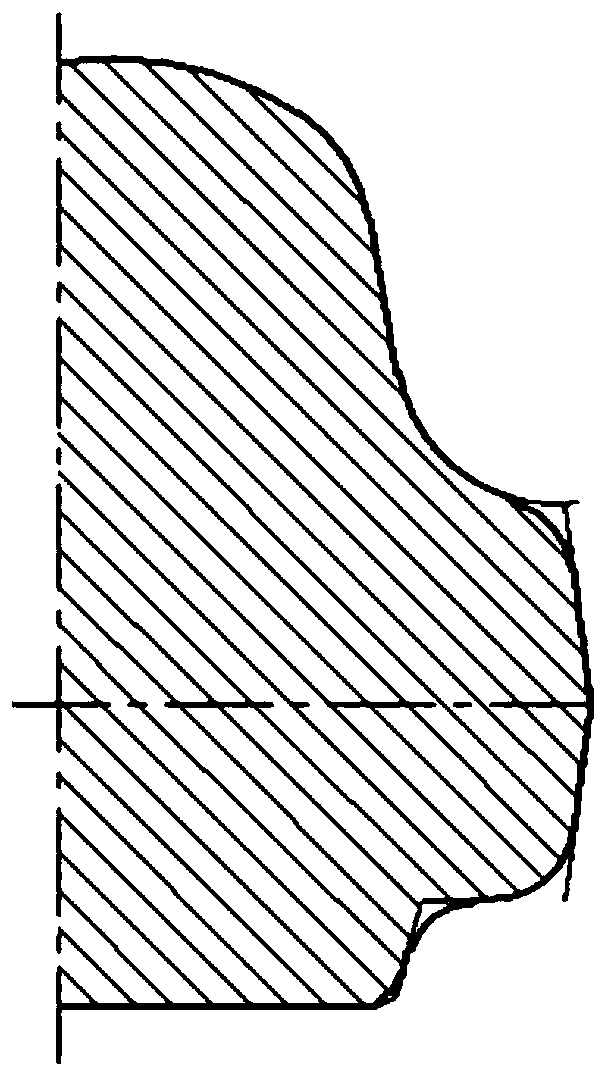

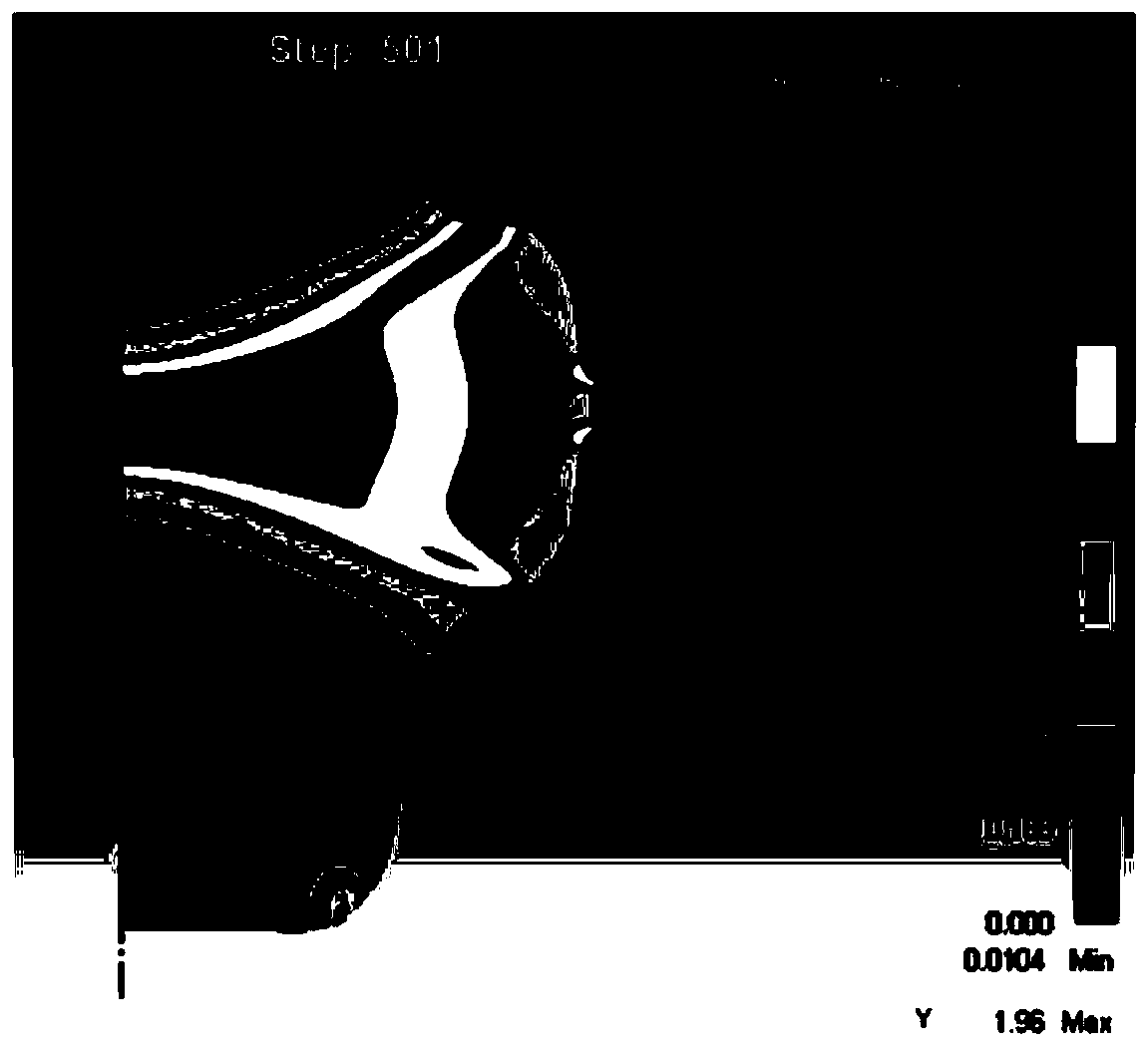

[0043] This forging process needs to control key parameters such as initial forging temperature, final forging temperature, and vertical dimension. Through the previous simulation calculation, the head fire mold is obtained as figure 1 It is shown that the minimum deformation of the pre-forging is in the range of 15%-20%, which can effectively improve the original grain of the blank and play a role in refining the grain.

[0044] 2. Final forging production:

[0045] After the pre-forging is produced, the hot material is returned to the furnace, and the pre-forging is heated. When the heating temperature reaches the preset temperature of the second fire, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com