Preparation method of ultra-high temperature ammonia decomposition catalyst, ultra-high temperature ammonia decomposition catalyst prepared by the method and application thereof

A catalyst, ammonia decomposition technology, applied in separation methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of slow diffusion, difficult to form cubic crystal system, etc., to reduce concentration, improve dispersion, The effect of improving high temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention proposes a preparation method of an ultra-high temperature ammonia decomposition catalyst, which comprises the following steps:

[0043] (1) Preparation of reconstituted materials:

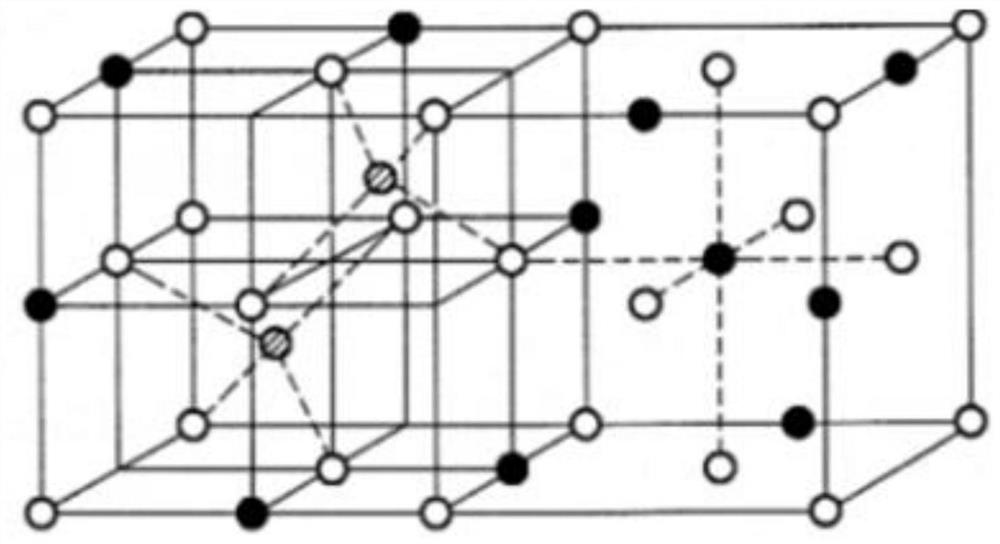

[0044] Carrying out the first roasting of the powder of the hydrotalcite-like composite oxide;

[0045] Prepare the first roasted product and sodium chloride to form the first mixed liquid, pass inert gas at a certain temperature, stir, stand still, cool, wash, suction filter, and vacuum-dry to obtain the reconstituted material;

[0046] (2) Preparation of catalyst carrier particles:

[0047] Mix the reconstituted material and the basic metal oxide evenly for the second roasting;

[0048] After the second calcined product is cooled, it is uniformly mixed with the oxygen storage component, pressed into cylindrical particles with a height of 15 to 20 mm and a diameter of 10 to 20 mm, and subjected to the third calcining to obtain cylindrical catalyst carrier particles; ...

Embodiment 1

[0092] Weigh 100 g of magnesium-aluminum binary hydrotalcite-like composite oxide powder, wherein the mass percentage of magnesium oxide is greater than 75%, and calcinate the powder at 850° C. for 2 hours. Take roasted product and sodium chloride, by molar ratio n(Mg 2+ ): n(Cl - ) = 1:2 to prepare the first mixed solution, and nitrogen gas was introduced at 80°C, stirred for 30 hours, then left to cool and washed to remove Cl - , AgNO 3 Check to no Cl - , and the reconstituted material was obtained after vacuum drying.

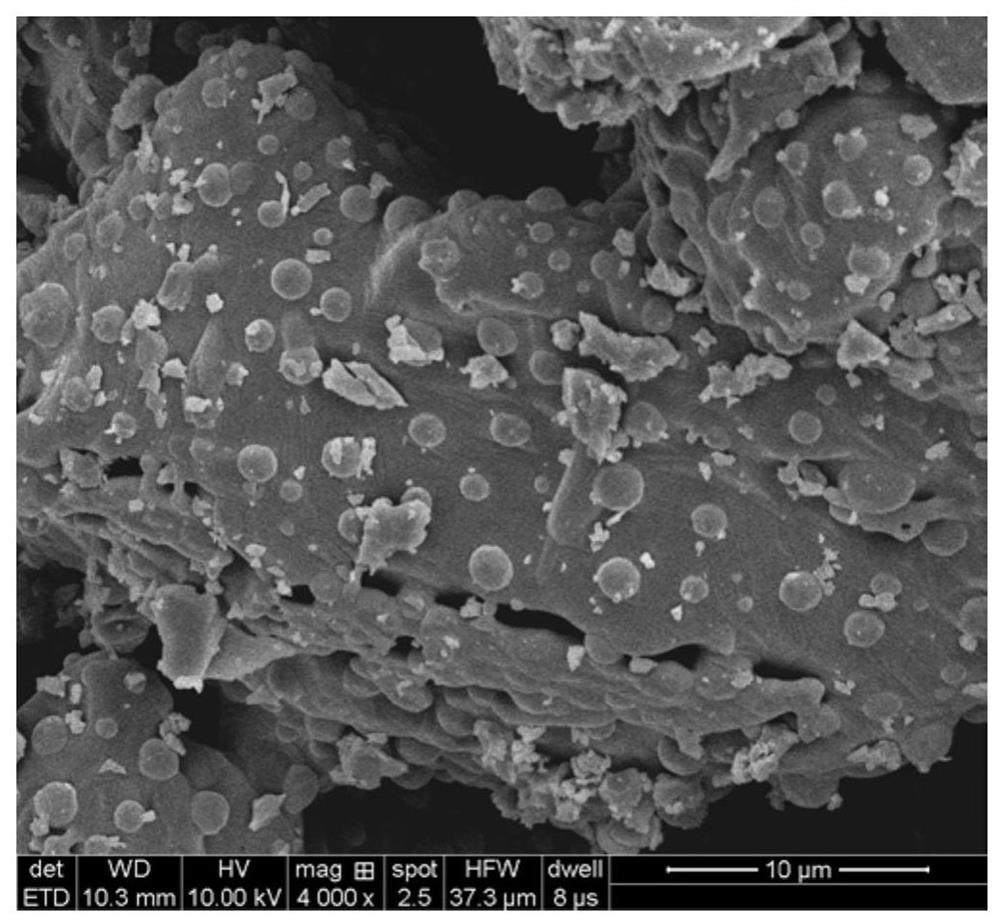

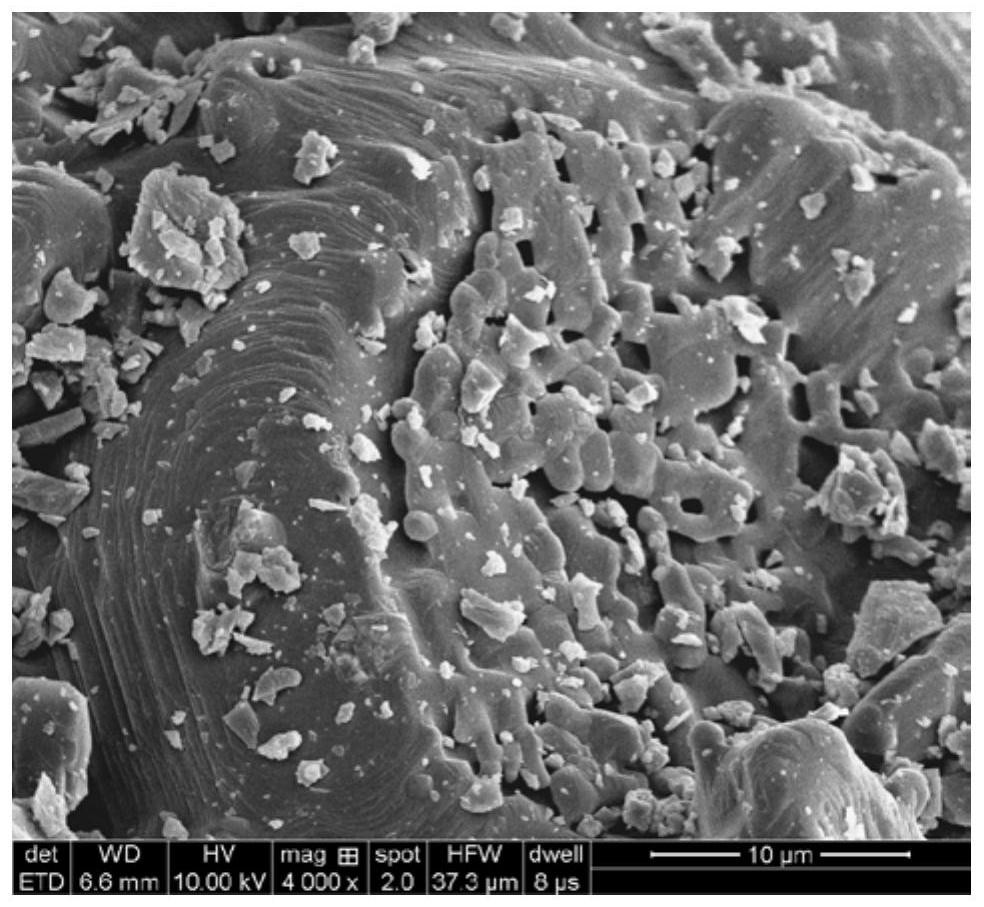

[0093] Take 5g of high-purity fused magnesia powder and 90g of the reconstituted material prepared above, mix evenly, pre-fire at 1400-1500°C for 16h, mix evenly with 10g of oxygen storage component after cooling, and press it into a cylindrical shape with a diameter of 15mm Particles, the cylindrical particles are calcined at 1450°C for 24 hours, and the catalyst carrier is obtained after cooling. 4g of molybdenum oxide and 6g of zirconium oxide are se...

Embodiment 2

[0097] Weigh 100 g of (Mg+Zn)-Al ternary hydrotalcite-like composite oxide powder, wherein the mass percentage of magnesium oxide is greater than 60%, and calcinate the powder at 850° C. for 2 hours. Take roasted product and sodium chloride, by molar ratio n(Mg 2+ +Zn 2+ ): n(Cl - ) = 1:2 to prepare the first mixed solution, and nitrogen gas was introduced at 80°C, stirred for 30 hours, then left to cool and washed to remove Cl- , AgNO 3 Check to no Cl - , and the reconstituted material was obtained after vacuum drying.

[0098] Take 5g of high-purity fused magnesia powder and 90g of the reconstituted material prepared above, mix evenly, pre-fire at 1400-1500°C for 16h, mix evenly with 3g of oxygen storage component after cooling, and press it into a cylindrical shape with a diameter of 15mm Particles, the cylindrical particles are calcined at 1450°C for 24 hours, and the catalyst carrier is obtained after cooling. The oxygen storage component of this embodiment selects i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com