Anti-alcohol liver-protecting health-care product and preparation method thereof

A technology for hangover and liver protection and health care products, applied in the fields of antitoxin, digestive system, food science, etc., can solve the problems of no hangover, liver protection effect, separation and removal of acetic acid bacteria cellulose, etc., and achieve large-scale industrial production Value, big marketing value, increase detoxification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] (1) Preparation of anti-alcoholic and liver-protecting health products

[0031] The hangover mechanism provided by the present invention adopts the hangover formula with alcohol dehydrogenase and acetaldehyde dehydrogenase as the main active ingredients, and takes orally the alcoholic acid bacteria cell and its metabolite acetate bacteria cellulose containing high activity Acetobacter extract of alcohol dehydrogenase and acetaldehyde dehydrogenase, which makes ethanol decomposed into acetic acid in the gastrointestinal tract. For acetic acid bacteria, the production pathway of acetic acid is basically the same as the metabolic pathway of ethanol in the human body. Ethanol is decomposed into acetic acid through first-pass metabolism, and acetic acid has little toxic effect on the human body, so it can effectively reduce the absorption of ethanol , to achieve the effect of hangover and anti-drunk.

[0032] The preparation process of the anti-alcohol and liver-protecting ...

example 1

[0043] Take the preparation of 1000 capsules as an example:

[0044] Gluconacetobacter xylinum (CGMCC 3917, references: Dehui Lin, Patricia Lopez-Sanchez, RuiLi, Zhixi Li*. Production of bacterialcellulose by GluconacetobacterhanseniiCGMCC 3917using only waste beer yeast asnutrient source, BioresourceTechnology, 2014, 151C: 113-119) Inoculate in liquid medium (medium composition: glucose 20g, yeast extract 5g, dipotassium hydrogen phosphate 1g, magnesium sulfate 15g, distilled water 1L, absolute ethanol 20mL), culture at 30°C, shaking cycle 150rpm, after 72 hours of culture, add 10 times the amount of 0.05M phosphate buffer solution with pH=6.5, homogenized at 12000rpm for 5 minutes in a high-speed homogenizer, added an enzyme stabilizer (such as ferric sulfate, final concentration 0.1mM) and freeze-dried (freeze-drying conditions: cell lysate Thickness: 6mm, pre-freezing at -20°C for 10h, drying at -50°C under 30Pa for 24h), to obtain dry powder of acetic acid bacteria extrac...

example 2

[0048] Take the preparation of 1000 capsules as an example:

[0049] Gluconacetobacter xylinum in Example 1 was inoculated in liquid medium (medium composition: glucose 20g, yeast extract 5g, dipotassium hydrogen phosphate 1g, magnesium sulfate 15g, distilled water 1L, absolute ethanol 20mL), cultured at 30°C, shaken Cycle 150rpm, after culturing for 72 hours, add 10 times the amount of 0.05M phosphate buffer with pH=6.5, homogenize at 12000rpm for 5 minutes in a high-speed homogenizer, add enzyme stabilizer (such as ferric sulfate, final concentration 0.1mM) and freeze-dry (Freeze-drying conditions: cell lysate with a thickness of 6mm, pre-frozen at -20°C for 10h, and dried at -50°C under 30Pa for 24h), to obtain dry powder of acetic acid bacteria extract in the form of white powder.

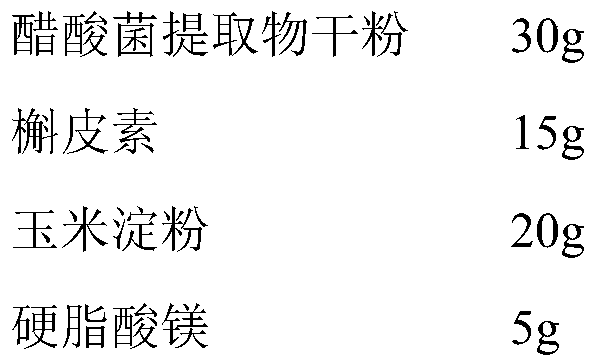

[0050] The obtained extract dry powder and auxiliary materials are fully mixed according to the following ratio:

[0051] Acetic acid bacteria extract dry powder (main ingredient) 30g

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com