Slow release algae removal microcapsule and preparation method thereof

A slow-release algae-killing microcapsule and microcapsule technology, applied in botany equipment and methods, herbicides and algicides, chemicals for biological control, etc. The problem of low utilization rate of disease, to achieve the effect of reducing the application amount and prolonging the effective period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

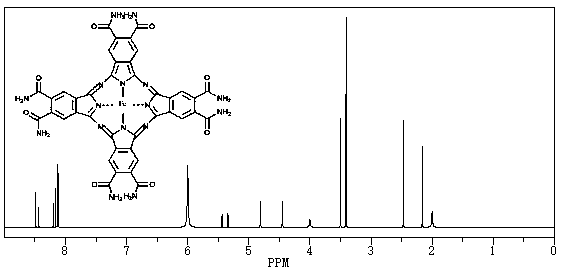

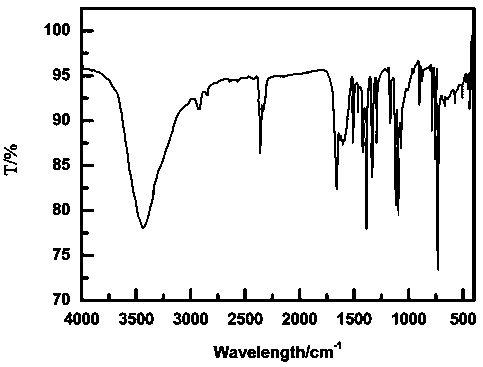

[0052] (1) Preparation of biomass-based molecular materials

[0053] (1.1) Mix 1 mol of pyromellitic anhydride, 25 mol of urea and 0.5 mol of ferric chloride hexahydrate, then add 1.2 mol of catalyst ammonium molybdate, add the above reactants into a mortar, mix well, and grind thoroughly. Put it in a three-necked flask and react at 180°C for 0.5h, and then raise the temperature to 250°C to continue the reaction for 5h after the reactants are dissolved. The obtained black solid product was soaked in 6 mol / L hydrochloric acid for 12 hours, filtered, and the filter cake was stirred in 85° C. distilled water for 35 minutes and then filtered, and the stirring and filtering operation was repeated until no solid precipitated out of the filtrate. After drying the filter residue, octaaminophthalocyanine iron is prepared.

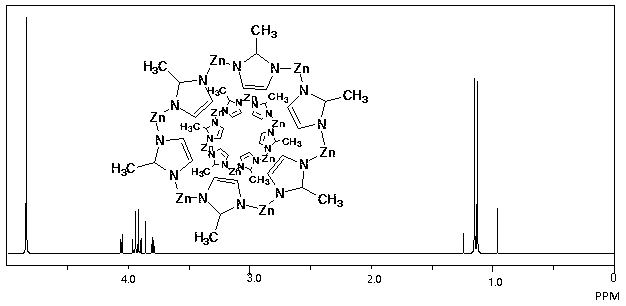

[0054] (1.2) Dissolve 1g of cellulose powder in 8g of absolute ethanol, add 5.0g of sodium hydroxide solution with a mass concentration of 20%, then add 1.2mL of m...

Embodiment 2

[0064] (1) Preparation of biomass-based molecular materials

[0065] (1.1) Mix 1 mol of pyromellitic anhydride, 26 mol of urea and 0.6 mol of ferric chloride hexahydrate, then add 1.3 mol of catalyst ammonium molybdate, add the above reactants into a mortar, mix well, and grind thoroughly. Put it in a three-necked flask and react at 200°C for 0.7h, and then raise the temperature to 240°C to continue the reaction for 5h after the reactants are dissolved. The obtained black solid product was soaked in 7 mol / L hydrochloric acid for 13 hours, filtered, and the filter cake was stirred in distilled water at 90°C for 40 minutes before filtering, and the stirring and filtering operation was repeated until no solid precipitated out of the filtrate. After drying the filter residue, octaaminophthalocyanine iron is prepared.

[0066] (1.2) Dissolve 1g of cellulose powder in 9g of absolute ethanol, add 5.5g of sodium hydroxide solution with a mass concentration of 25%, then add 1.3mL of m...

Embodiment 3

[0076] (1) Preparation of biomass-based molecular materials

[0077] (1.1) Mix 1 mol of pyromellitic anhydride, 24 mol of urea and 0.4 mol of ferric chloride hexahydrate, then add 1.1 mol of catalyst ammonium molybdate, add the above reactants into a mortar, mix well, and grind thoroughly. Place it in a three-necked flask and react at 160°C for 1 hour. After the reactants are dissolved, raise the temperature to 260°C and continue the reaction for 4 hours. The obtained black solid product was soaked in 5 mol / L hydrochloric acid for 12 hours, filtered, and the filter cake was stirred in 85° C. distilled water for 35 minutes and then filtered, and the stirring and filtering operation was repeated until no solid precipitated out of the filtrate. After drying the filter residue, octaaminophthalocyanine iron is prepared.

[0078] (1.2) Dissolve 1g of cellulose powder in 9g of absolute ethanol, add 5.0g of sodium hydroxide solution with a mass concentration of 23%, then add 1.0mL of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com