High-performance temperature equalization device

A high-performance, liquid-absorbing core technology, which is applied in the direction of cooling/ventilation/heating transformation, can solve the problems of restricting product quality, performance improvement, unfavorable wide use of temperature equalization devices, and decline in welding quality, so as to expand the scope of use and areas, efficient and stable performance indicators, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the orientation terms such as left, middle, right, up, and down in the examples of the present invention are only relative concepts or refer to the normal use state of the product, and should not be considered as restrictive .

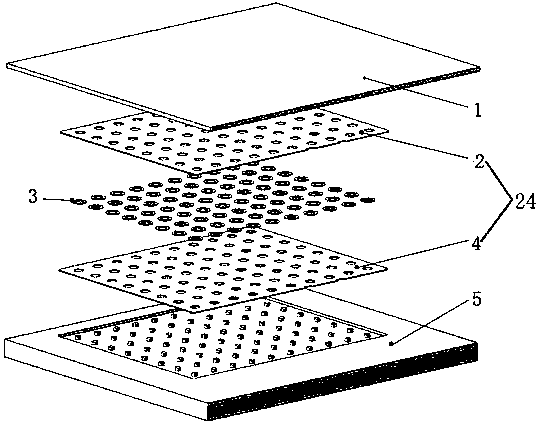

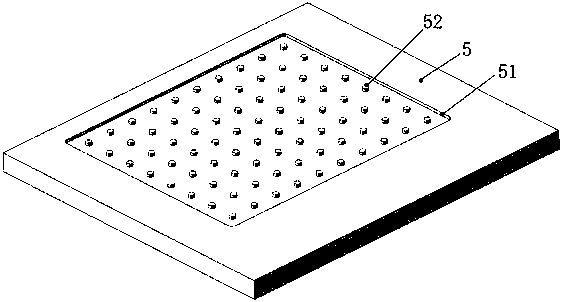

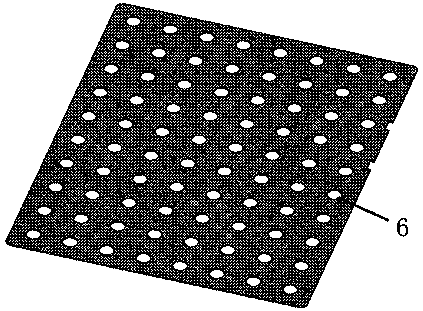

[0029] A high-performance temperature equalization device, such as figure 1 , figure 2 , Figure 7 and Figure 8 As shown, it includes a base plate 5, a liquid-absorbing core 24 and a cover plate 1. The cover plate 1 is fixed on the base plate 5, and a square cavity 51 is provided between the cover plate 1 and the base plate 5. The liquid-absorbing core 24 is located in the cavity 51, and a supporting column 52 is distributed in the cavity 51, and the supporting column 52 is arranged through the liquid-absorbing core 24. The two ends of the supporting column 52 It is fixedly connected with the bottom plate 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com