A kind of circular dot silver paste and preparation method thereof

A circular, silver-pointed technology, used in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc., can solve the problems of inconvenient communication, slow improvement, and can not meet the miniaturization of MLCI products. requirements and other issues, to achieve the effect of full graphics, improved bonding force, reliable performance and excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The gist of the present invention is to adjust the reasonable ratio of crystalline large-grained silver powder, silver micropowder, organic carrier, glass or inorganic oxide, and organic additives, select a suitable particle size, and automatically display circular dots after printing, which are clear and uniform. After firing, the dot silver paste matches the shrinkage of the porcelain body, which plays a good role in connecting the upper and lower electrode layers. The final product obtained has no short-circuit or open-circuit defects, and has excellent reliability and electrical properties. The proportions mentioned in the examples are not limitations of the present invention, and the selection of other silver paste formulations under the concept of the present invention may be adapted to local conditions and have no substantial impact on the results.

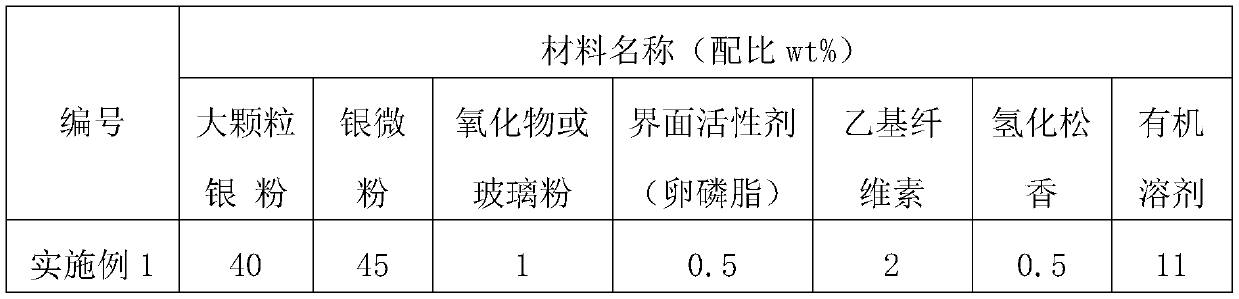

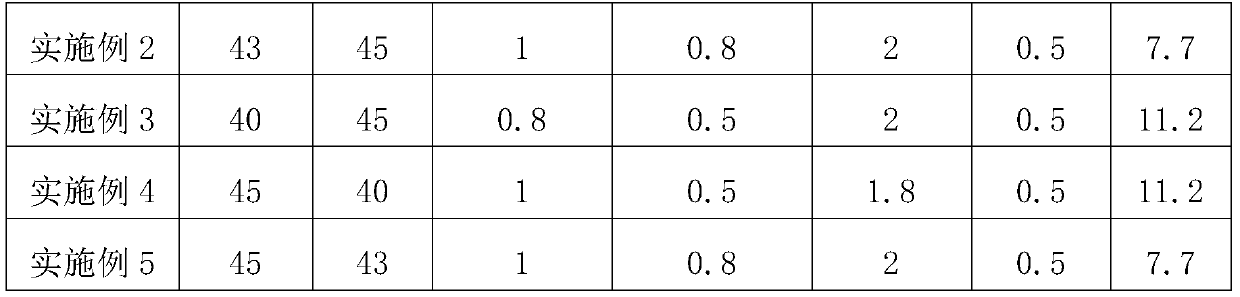

[0011] The formula design of the best embodiment of the present invention is as shown in table 1:

[0012] Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com