Colored photosensitive resin composition, color filter and display device

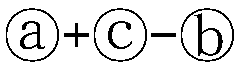

A technology of photosensitive resin and composition, which is applied in the direction of instruments, optics, optical filters, etc., can solve the problems of insufficient reliability of NMP dissolution, the realization of height difference and the inability to perfectly solve the process margin, etc., and achieve excellent resolution, Excellent light-shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0145] Production example 1: Production of alkali-soluble resin B1

[0146] In a separable flask with an inner volume of 1 L equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen gas introduction tube, 277 g of propylene glycol monomethyl ether acetate (hereinafter referred to as "PGMEA") was added, and the temperature was raised to After 80°C, 3,4-epoxytricyclic [5.2.1.0 2,6 ]decane-9-yl acrylate with 3,4-epoxytricyclo[5.2.1.0 2,6 ] a mixture of decane-8-yl acrylate [50:50 (molar ratio)] (that is, the compound represented by the following chemical formula 1-1 and chemical formula 1-2 [R a =H]) 301g, 49g of methacrylic acid and 23g of azobisdimethylvaleronitrile dissolved in 350g of methoxybutyl acetate, and carried out aging for 3 hours to obtain a copolymer solution (solid Ingredient concentration 35.0%). The acid value (dry) of the obtained copolymer was 60.2 mgKOH / g, and the weight average molecular weight (Mw) was 9,000.

[0147...

manufacture example 2

[0152] Production example 2: Production of alkali-soluble resin B2

[0153] In a separable flask with an inner volume of 1 L equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen gas introduction tube, 277 g of propylene glycol monomethyl ether acetate (hereinafter referred to as "PGMEA") was added, and the temperature was raised to After 80°C, dropwise add 3,4-epoxytricyclic [5.2.1.0 2,6 ]decane-9-yl acrylate with 3,4-epoxytricyclo[5.2.1.0 2,6 ] a mixture of decane-8-yl acrylate [50:50 (molar ratio)] (that is, the compound represented by the above chemical formula 1-1 and chemical formula 1-2 [R a =H]) 301g, 49g of methacrylic acid and 23g of azobisdimethylvaleronitrile dissolved in 350g of methoxybutyl acetate, and carried out aging for 3 hours to obtain a copolymer solution (solid Ingredient concentration 35.0%). The acid value (dry) of the obtained copolymer was 61.5 mgKOH / g, and the weight average molecular weight (Mw) was 15,000...

manufacture example 3

[0154] Production example 3: Production of alkali-soluble resin B3

[0155] In a separable flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen introduction tube, add 72 parts by weight of methyl methacrylate, 3 parts by weight of acrylic acid, and 2 times the total amount of monomers. Propylene glycol monomethyl ether acetate (hereinafter referred to as "PGMEA"), 5 parts by weight of 2,2'-azobis(2-methylbutyronitrile) based on the total amount of monomers (100 parts by weight) , so that it dissolves evenly. Thereafter, the mixture was stirred at 85° C. for 2 hours under a nitrogen stream, and reacted again at 100° C. for 1 hour. To the obtained solution, 25 parts by weight of glycidyl methacrylate, 10 parts by weight of triethylamine relative to glycidyl methacrylate, and 1 part by weight of hydroquinone relative to glycidyl methacrylate were added. , and PGMEA in which the total weight of the monomer and glycidyl methacrylate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com