Zinc-aluminum-magnesium intermediate alloy capable of supplementing lost magnesium element in zinc bath and method thereof

A master alloy, zinc-aluminum-magnesium technology, applied in metal material coating process, coating, hot-dip plating process, etc., can solve the problems of reduced magnesium content, high vapor pressure, oxidative burning loss, etc., and achieve faster alloy dissolution. , the fluctuation of magnesium content is reduced, and the effect of improving the efficiency of magnesium supplementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

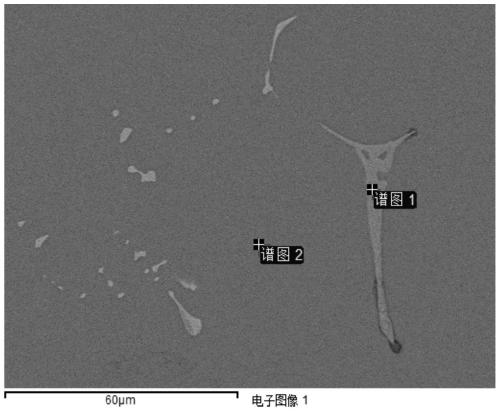

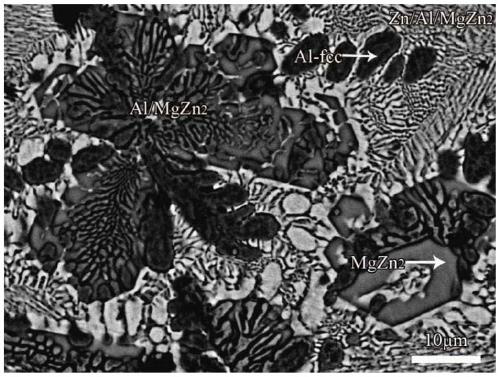

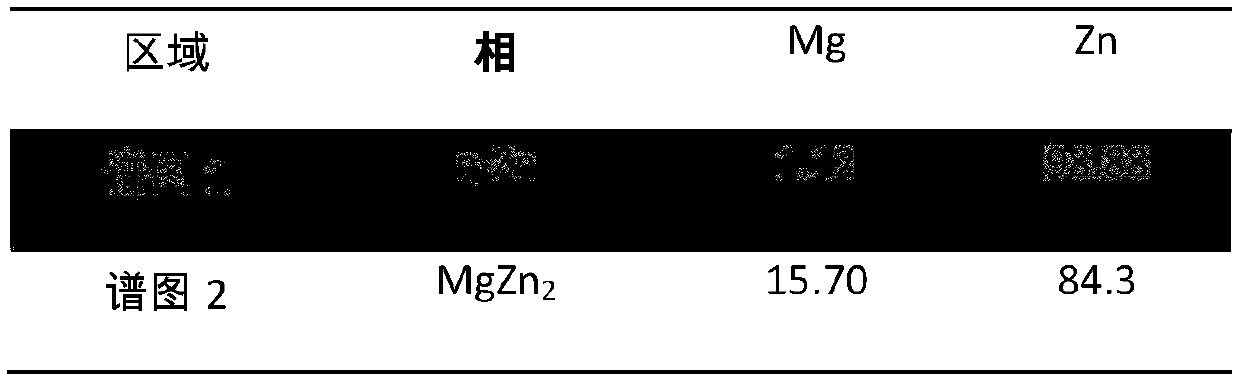

Image

Examples

Embodiment 1

[0023] Use industrial pure zinc, pure aluminum and pure magnesium ingots to configure 1000 grams of zinc-aluminum-magnesium alloy according to Zn-6wt.%Al-4%Mg, put the graphite crucible into the well-type resistance furnace and heat it to dark red, and then put the small pieces of zinc Ingots and aluminum ingots are put into crucibles, and the temperature continues to rise to 680°C for melting. After the zinc and aluminum are completely melted, sprinkle a covering agent on the surface of the alloy liquid, the composition of the covering agent is 50% NaCl+25% KCl+25% Na 3 AlF 6 . Clamp the magnesium block with pliers and press it into the bottom of the alloy liquid. After the magnesium block is completely melted, use a glass rod to properly stir the metal liquid. After standing at 580°C for about 10 minutes, remove the inclusions and covering agent on the surface of the metal liquid. The alloy solution is poured into a metal mold with an inner cavity size of 20mm×100mm and a ...

Embodiment 2

[0025] Use industrial pure zinc, pure aluminum and pure magnesium ingots to configure 1000 grams of zinc-aluminum-magnesium alloy according to Zn-6wt.%Al-6%Mg, put the graphite crucible into the well-type resistance furnace and heat it to dark red, and then put the small pieces of zinc Ingots and aluminum ingots are put into crucibles, and the temperature continues to rise to 680°C for melting. After the zinc and aluminum are completely melted, sprinkle a covering agent on the surface of the alloy liquid, the composition of the covering agent is 50% NaCl+25% KCl+25% Na 3 AlF 6 . Clamp the magnesium block with pliers and press it into the bottom of the alloy liquid. After the magnesium block is completely melted, use a glass rod to properly stir the metal liquid. After standing at 580°C for about 10 minutes, remove the inclusions and covering agent on the surface of the metal liquid. The alloy solution is poured into a metal mold with an inner cavity size of 20mm×100mm and a ...

Embodiment 3

[0027] Use industrial pure zinc, pure aluminum and pure magnesium ingots to configure 1000 grams of zinc-aluminum-magnesium alloy according to Zn-6wt.%Al-6%Mg, put the graphite crucible into the well-type resistance furnace and heat it to dark red, and then put the small pieces of zinc Ingots and aluminum ingots are put into crucibles, and the temperature continues to rise to 680°C for melting. After the zinc and aluminum are completely melted, sprinkle a covering agent on the surface of the alloy liquid, the composition of the covering agent is 50% NaCl+25% KCl+25% Na 3 AlF 6 . Clamp the magnesium block with pliers and press it into the bottom of the alloy liquid. After the magnesium block is completely melted, use a glass rod to properly stir the metal liquid. After standing at 580°C for about 10 minutes, remove the inclusions and covering agent on the surface of the metal liquid. The alloy solution is poured into a metal mold with an inner cavity size of 20mm×100mm and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com