Efficient self-produced gas foam fracturing fluid and construction method thereof

A technology of foam fracturing fluid and construction method, which is applied in the direction of chemical instruments and methods, earth drilling, mining fluids, etc. It can solve the problems of hidden safety hazards, poor solubility, high toxicity, etc., achieve rapid flowback, increase net pressure, Effects that reduce lingering damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

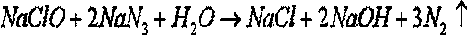

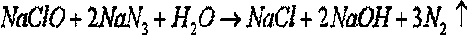

[0021] In order to overcome the existing problems of easy generation of by-products such as nitric oxide, high toxicity, poor solubility and potential safety hazards, the present invention provides a high-efficiency self-produced gas foam fracturing fluid and a construction method. The present invention introduces efficient and safe chemical reactions, The generated gas is safe and controllable, and high-quality foam is quickly formed to produce foam fracturing fluid. While reforming the formation, it can play the dual role of energy enhancement and drainage, reducing formation blockage damage, thereby achieving the purpose of increasing production.

[0022] A high-efficiency self-generating foam fracturing fluid provided in the present invention, the foam fracturing fluid is composed of base fluid, gas-generating liquid and heat-generating agent, wherein the mass ratio of base fluid, gas-generating liquid and heat-generating agent is 100 :(30-42):(5-9).

[0023] In the presen...

Embodiment 2

[0033] A high-efficiency self-generating foam fracturing fluid provided in the present invention, the foam fracturing fluid is composed of base fluid, gas-generating fluid and heat-generating agent. In this embodiment, the The mass ratio is 100:35:7; wherein, the base fluid consists of 9 parts of thickened drag reducer EM30S, 40 parts of sodium azide, 6 parts of foaming agent, 4 parts of clay stabilizer, water 1700 parts; the gas-generating liquid consists of 15 parts by weight of sodium hypochlorite, 7 parts of potassium nitrate, and 800 parts of water; the heat-generating agent is calcium oxide.

[0034] In this embodiment, the base fluid and the gas-producing fluid are sucked into the well by the mixer truck in proportion and pumped into the well together, and the heat generating agent in proportion is pumped into the well along with the proppant. After the liquid enters the downhole, the reaction temperature is the formation temperature, about 45-65°C, and the gas producti...

Embodiment 3

[0042] A high-efficiency self-generating foam fracturing fluid provided in the present invention, the foam fracturing fluid is composed of base fluid, gas-generating liquid and heat-generating agent. In this embodiment, the base fluid, gas-generating liquid, and heat-generating agent are composed of , the mass ratio is 100:42:9; wherein, the base fluid consists of 10 parts of thickened drag reducer EM30, 50 parts of sodium azide, 12 parts of foaming agent, 6 parts of clay stabilizer, 2000 parts of water; the gas-generating liquid consists of 20 parts of sodium hypochlorite, 8 parts of potassium nitrate and 800 parts of water; the heat generating agent is calcium oxide.

[0043] In this embodiment, the base fluid and the gas-producing fluid are sucked into the well by the mixer truck in proportion and pumped into the well together, and the heat generating agent in proportion is pumped into the well along with the proppant. After the liquid enters the downhole, the reaction temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com