Glass fiber reinforced polypropylene composite material with high thermo-oxidative aging resistance and preparation method of glass fiber reinforced polypropylene composite material

A composite material, high heat resistance technology, applied in the field of polymer materials, can solve the problems of lack of application, poor thermal oxygen aging ability, etc., achieves good performance retention rate, improved thermal oxygen aging ability, and improved heat resistance Effects of Oxygen Aging Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

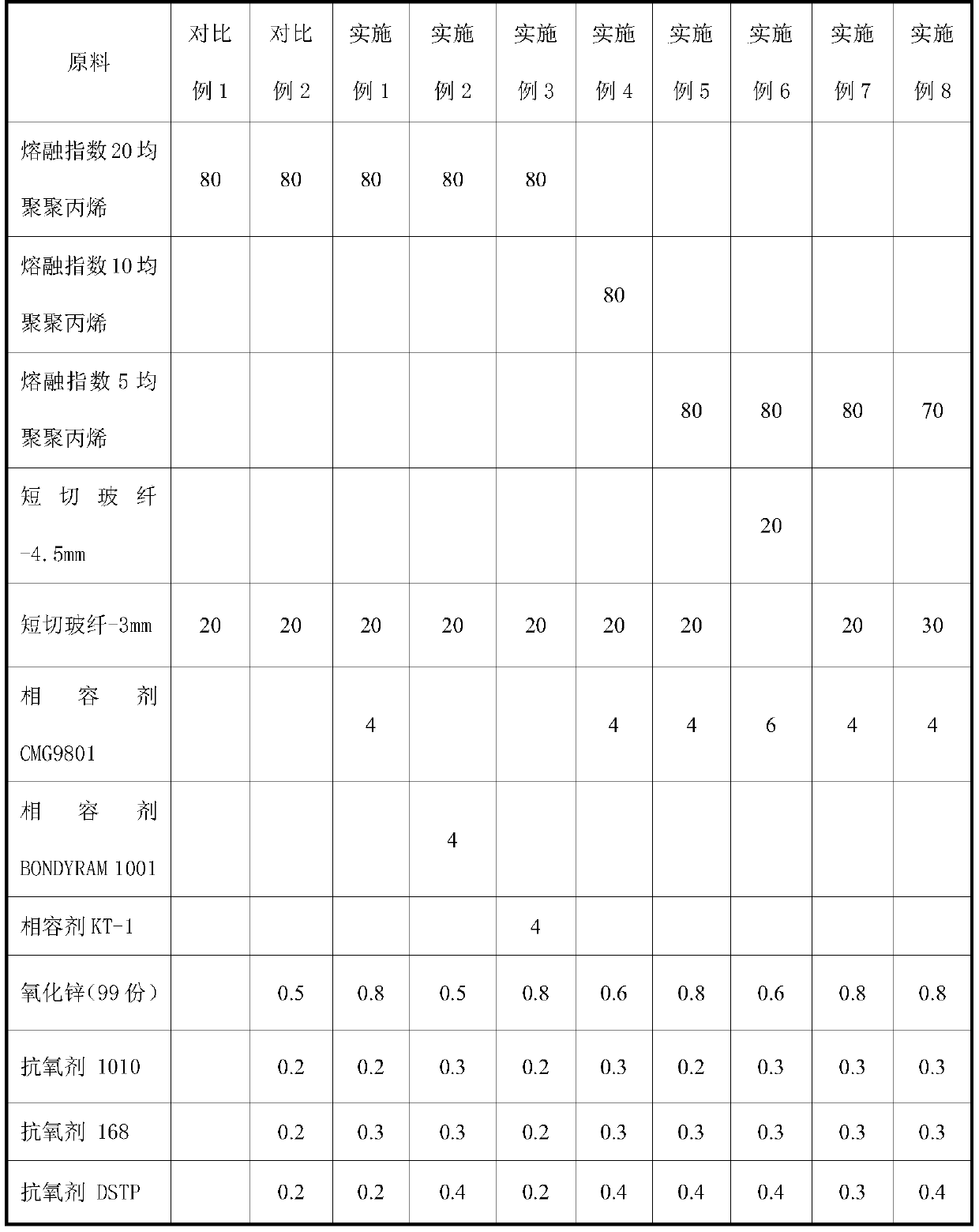

Embodiment 1

[0043] (1) Weigh various raw materials according to the weight percentage in Table 1: 80 parts of homopolypropylene with a melt index of 20g / 10min, 20 parts of 3mm glass fiber, antioxidant 1010: antioxidant 168: antioxidant DSTP It is 0.2:0.3:0.2, 0.8 parts of zinc oxide, and CMG98014 parts of compatibilizer.

[0044] (2) Add polypropylene to the main feed port of the twin-screw extruder. At the same time, the glass fiber is fed into the twin-screw extruder through the side feed port, fully plasticized and mixed at 190℃~210℃, and then extruded and cooled. Granulation and cutting.

Embodiment 2

[0046] (1) Weigh various raw materials according to the weight percentage in Table 1: 80 parts of homopolypropylene with a melt index of 20g / 10min, 20 parts of 3mm glass fiber, antioxidant 1010: antioxidant 168: antioxidant DSTP It is 0.3:0.3:0.4, 0.5 parts of zinc oxide, and 14 parts of compatibilizer BONDYRAM 100.

[0047] (2) Add polypropylene to the main feed port of the twin-screw extruder. At the same time, the glass fiber is fed into the twin-screw extruder through the side feed port, fully plasticized and mixed at 190℃~210℃, and then extruded and cooled. Granulation and cutting.

Embodiment 3

[0049] (1) Weigh various raw materials according to the weight percentage in Table 1: 80 parts of homopolypropylene with a melt index of 20g / 10min, 20 parts of 3mm glass fiber, antioxidant 1010: antioxidant 168: antioxidant DSTP It is 0.2:0.2:0.2, 0.8 parts of zinc oxide, and 14 parts of compatibilizer KT.

[0050] (2) Add polypropylene to the main feed port of the twin-screw extruder, and at the same time, the glass fiber is fed into the twin-screw extruder through the side feed port, fully plasticized and mixed at 190℃~210℃, extruded and cooled Granulation and cutting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com