Preparation method of environment-friendly crosslinking type fluorocarbon polymer nanoemulsion

A nano-emulsion, cross-linked technology, applied in the field of preparation of environmentally friendly cross-linked fluorocarbon polymer nano-emulsion, to achieve energy saving, low skin irritation, good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

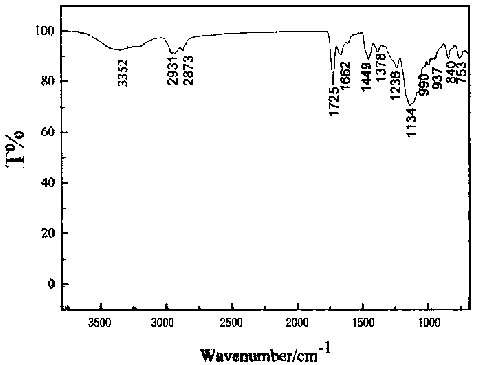

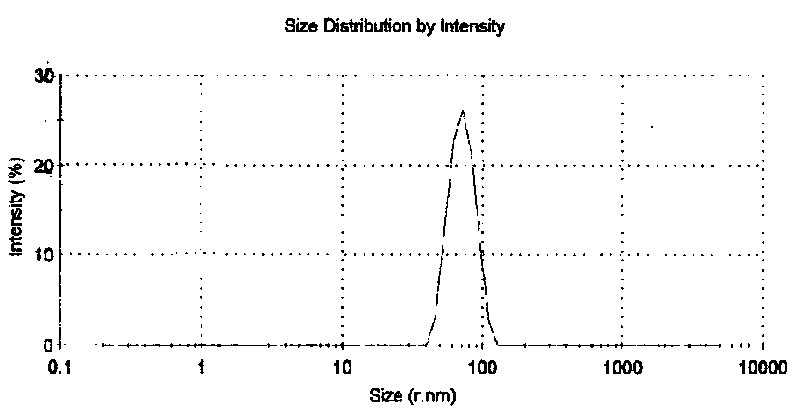

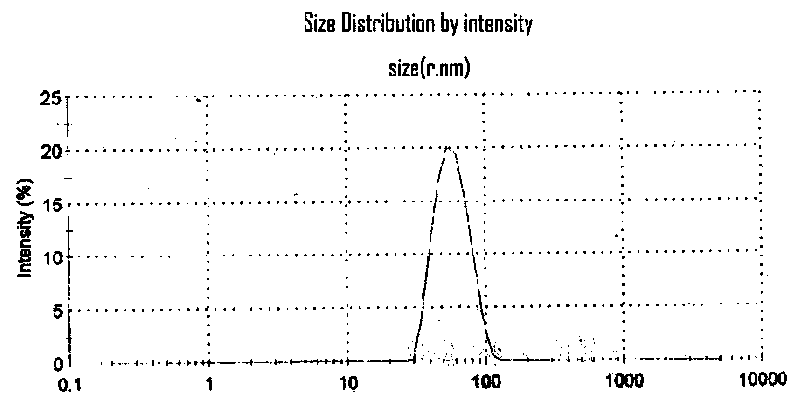

Image

Examples

Embodiment 1

[0020] In a 250mL four-neck flask equipped with a stirrer, reflux condenser, and dropping funnel, add 0.28g of amphoteric surfactant betaine and 0.56g of anionic surfactant amino acid compound surfactant and 35.00g of deionized water, stirred and heated to 80°C in a water bath. Add 10% of the mixed monomer and 10% of the initiator solution dropwise within 15 minutes, and continue to keep warm for 15 minutes after the dropwise addition is completed. Then the remaining initiator emulsion and mixed monomers were added dropwise into the four-necked flask within 3.0 hours. After the dropwise addition was completed, the temperature was raised to 90° C., and the temperature was continued for 30 minutes. The temperature was lowered to 40° C., and the acrylate nanopolymer emulsion was obtained after filtering out the material. Wherein the composition of the mixed monomer is 13.50g of butyl acrylate, 12.20g of methyl methacrylate, and 2.16g of functional monomers; the content of the in...

Embodiment 2

[0022] In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 0.60 g of amphoteric surfactant betaine and 0.90 g of anionic surfactant compound surfactants and 35.00 g of deionized water , stirred and heated to 80°C in a water bath. Add 20% of the mixed monomer and 20% of the initiator solution dropwise within 15 minutes respectively, and continue to keep warm for 15 minutes after the dropping is completed. Then the remaining initiator emulsion and mixed monomers were added dropwise into the four-necked flask within 3.0 hours. After the dropwise addition was completed, the temperature was raised to 90° C., and the temperature was continued for 40 minutes. The temperature was lowered to 40° C., and the acrylate nanopolymer emulsion was obtained after filtering out the material. Wherein the mixture monomer is combined into 12.00g of butyl acrylate, 15.00g of methyl methacrylate, and 3.00g of functional monomers; the content of the i...

Embodiment 3

[0024] In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 1.20 g of amphoteric surfactant betaine and 0.60 g of anionic surfactant compound surfactants and 30.00 g of deionized water , stirred and heated to 80°C in a water bath. Add 10% of the mixed monomer and 10% of the initiator solution dropwise within 15 minutes, and continue to keep warm for 15 minutes after the dropwise addition is completed. Then the remaining initiator emulsion and mixed monomers were added dropwise into the four-necked flask within 3.0 hours. After the dropwise addition was completed, the temperature was raised to 90° C., and the temperature was continued for 40 minutes. The temperature was lowered to 40° C., and the acrylate nanopolymer emulsion was obtained after filtering out the material. Wherein the composition of mixed monomer is butyl acrylate of 14g, methyl methacrylate of 13.5g, functional monomer of 2.5g; The content of initiator solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com