Tetrafluoroethylene-based copolymer and its preparation method

A tetrafluoroethylene copolymer and tetrafluoroethylene technology, which are applied in the field of tetrafluoroethylene copolymer and its preparation, can solve the problems of poor thermal stability, low melting point of the product, and reduced durability of the composition, and achieve enhanced flexibility. , the effect of improving transparency and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

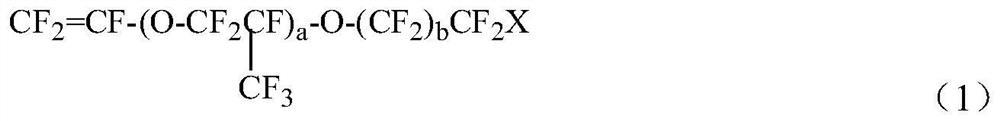

Method used

Image

Examples

Embodiment 1

[0044] (1) In an oxygen-free 100L stainless steel polymerization kettle, add 60L of deionized water, 500g of perfluoropolyether ammonium carboxylate CF 3 CF 2 OCF 2 OCF 2 COONH 4 (40wt%), after vacuumizing the inside of the polymerizer, add the mixture of 3kg perfluorooctane, perfluoroheptane and perfluorocyclohexane, 1000g of PPVE and 600g of perfluoropropenyl alkoxy ether CF 2 = CFCF 2 OCF 2 C F(CF 3 )OC 3 f 7 , and then filled with methane to increase the pressure in the polymerization kettle by 0.5MPa, and the temperature of the polymerization kettle was raised to 90°C. When the pressure reached 2.7MPa, the prepared 45g potassium persulfate and ammonium persulfate mixture was quickly pumped into the polymerization kettle through the auxiliary pump Among them, the sign of the start of the polymerization reaction is that the pressure in the polymerization tank begins to drop;

[0045] (2) Continuously add tetrafluoroethylene monomer to keep the temperature and press...

Embodiment 2

[0048] (1) In an oxygen-free 100L stainless steel polymerization kettle, add 60L of deionized water, 500g of perfluoropolyether ammonium carboxylate CF 3 CF 2 OCF 2 OCF 2 COONH 4 (40wt%), after vacuumizing the inside of the polymerizer, add the mixture of 5kg perfluorooctane, perfluoroheptane and perfluorocyclohexane, 800g of PPVE and 300g of perfluoropropenyl alkoxy ether CF 2 = CFCF 2 OCF 2 CF(CF 3 )OC 3 f 7 , then fill in methane to increase the pressure in the polymerization kettle by 0.6MPa, raise the temperature of the polymerization kettle to 85°C, and when the pressure reaches 2.7MPa, quickly inject the prepared 100g potassium persulfate and ammonium persulfate mixture into the polymerization kettle through the auxiliary pump Among them, the sign of the start of the polymerization reaction is that the pressure in the polymerization tank begins to drop;

[0049] (2) Continuously add tetrafluoroethylene monomer to keep the temperature and pressure constant in th...

Embodiment 3

[0052] (1) In an oxygen-free 100L stainless steel polymerization kettle, add 60L of deionized water, 500g of perfluoropolyether ammonium carboxylate CF 3 CF 2 OCF 2 OCF 2 COONH 4 (40wt%), after vacuumizing the inside of the polymerizer, add the mixture of 5kg perfluorooctane, perfluoroheptane and perfluorocyclohexane, 600g of PPVE and 200g of perfluoropropenyl alkoxy ether CF 2 = CFCF 2 OCF 2 CF(CF 3 )OC 3 f 7 , then fill in methane to increase the pressure in the polymerization kettle by 0.6MPa, raise the temperature of the polymerization kettle to 85°C, and when the pressure reaches 2.7MPa, quickly inject 200g of the prepared mixed solution of potassium persulfate and ammonium persulfate into the polymerization kettle through the auxiliary pump Among them, the sign of the start of the polymerization reaction is that the pressure in the polymerization tank begins to drop;

[0053] (2) Continuously add tetrafluoroethylene monomer to keep the temperature and pressure c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com