Continuous Coagulation Method of Fluoropolymer Emulsion and Pipeline Emulsifier

A technology of polymer emulsion and coagulation method, which is applied in the field of continuous coagulation method of fluorine-containing polymer emulsion and pipeline emulsifier, which can solve the problems of poor demulsification effect and increased steam consumption, so as to increase additional cost and improve utilization rate , the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

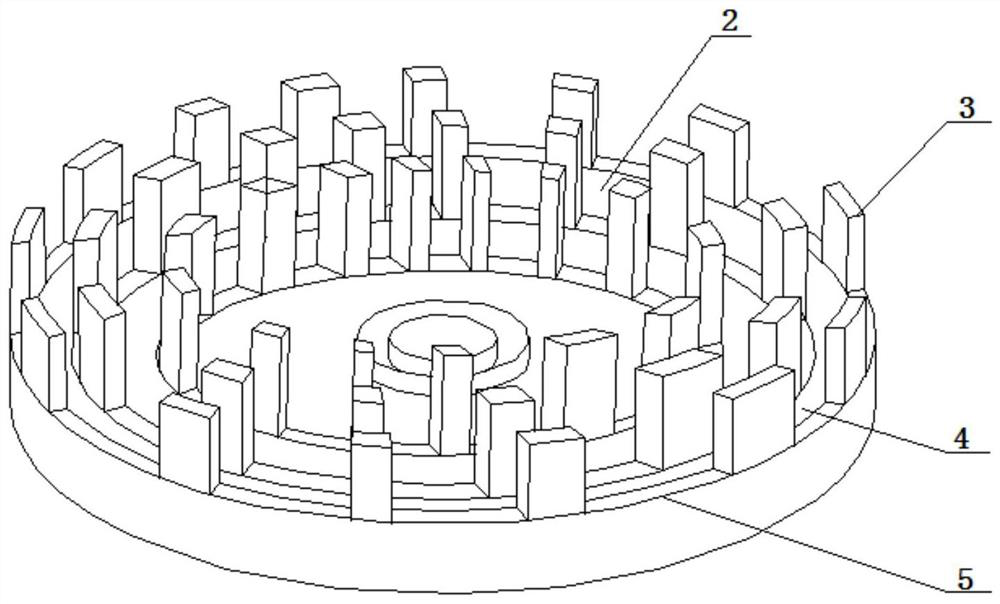

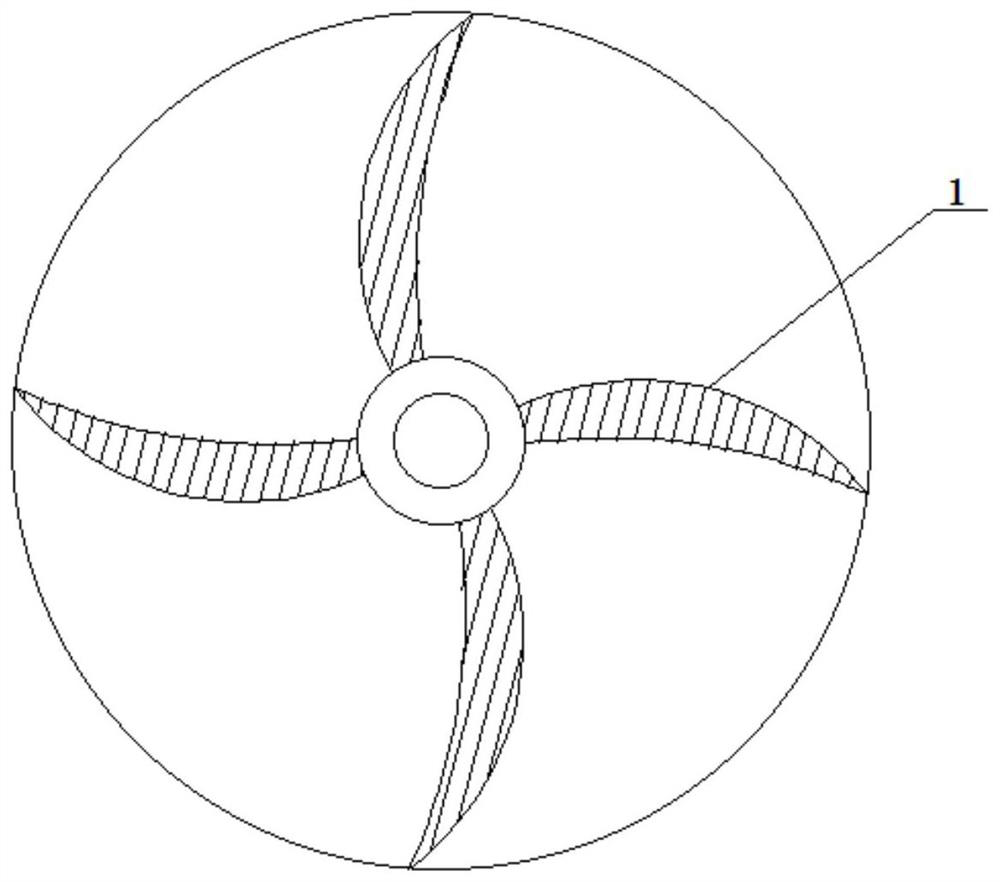

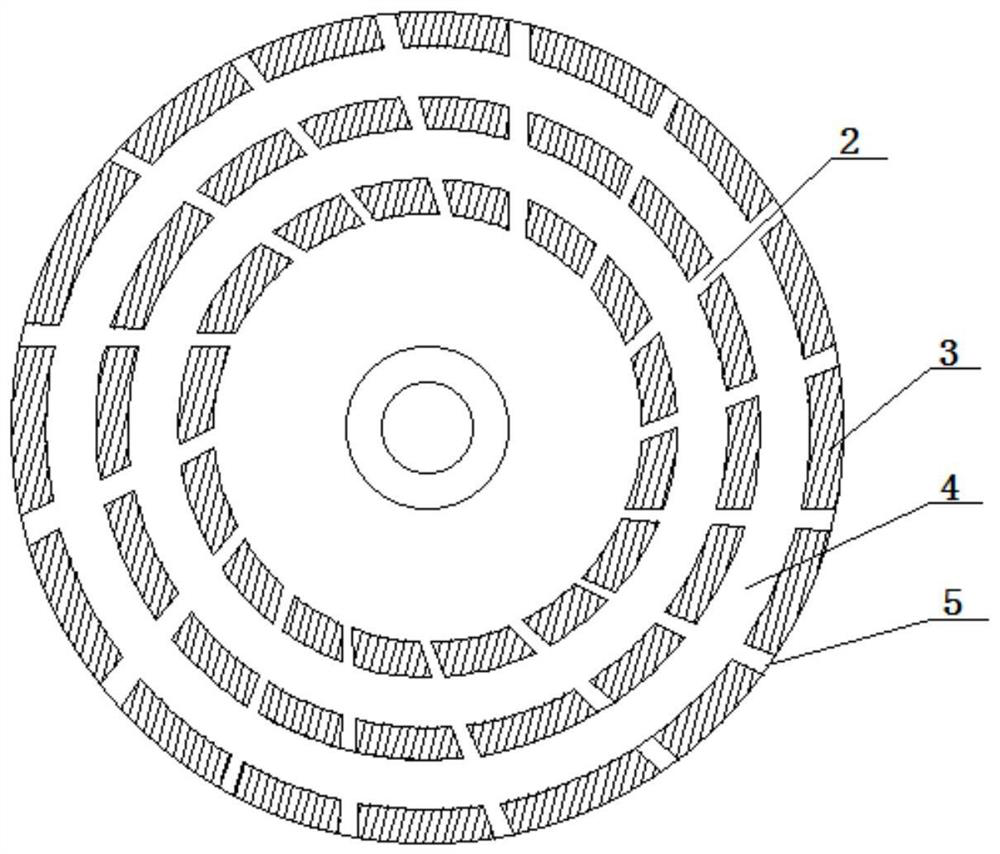

[0041] A pipeline type emulsifier with a three-layer stator-rotor structure is selected, including an outer layer stator-rotor and two inner-layer stator-rotors. The radial gap between the stator and the rotor of the inner stator and rotor is 0.4mm. There are 3 diversion grooves 4 on the stator and rotor of the inner layer, and 4 diversion grooves 4 on the stator and rotor of the inner layer. The number of tooth structures 3 in the groove 4 is 20, and the tangent angle between the flow channel 2 and the guide groove 4 at the flow channel opening 5 is 60°, and the experiment is carried out.

[0042] Put 1000L polyperfluorinated ethylene propylene emulsion, the emulsion particle size is 0.168μm, put it into the intermediate storage tank from the polymerization kettle, add water into the intermediate tank, the ratio of emulsion to water is 1:2, and transport it into the intermediate tank through the pipeline Pipeline emulsifier, after increasing the rotational speed of the stator...

Embodiment 2

[0044] The pipeline type emulsifier with two-layer stator and rotor structure is adopted, including an outer layer of stator and rotor and an inner layer of stator and rotor. The radial gap between the stator and the rotor of the inner stator and rotor is 0.4 mm, and there are 3 diversion grooves 4 on the stator and rotor of the inner layer, and the number of tooth structures 3 in each diversion groove 4 is 30. The tangent angle between the diversion groove 4 and the runner mouth 5 is 30°, and the experiment is carried out.

[0045] Put 1000L polytetrafluoroethylene emulsion, the emulsion particle size is 0.165μm, put it into the intermediate storage tank from the polymerization kettle, add water into the intermediate tank, the ratio of emulsion to water is 1:2, and transport it into the pipeline through the pipeline Type emulsifier, increase the rotational speed of the stator and rotor of the pipeline emulsifier to 10,000 rpm, open the outlet, and transport the demulsified po...

Embodiment 3

[0047] A pipeline type emulsifier with a four-layer stator-rotor structure is selected, including an outer layer of stator-rotor and three inner-layer stator-rotors. There are 3 diversion grooves 4, and there are 4 diversion grooves 4 on the second stator and rotor of the inner layer, and 5 diversion grooves 4 on the stator and rotor of the inner third layer, and the number of tooth structures 3 of each diversion groove 4 is 20, the tangent angle between the runner 2 and the guide groove 4 at the runner mouth 5 is 90°, and the experiment is carried out.

[0048] Put 1000L polyvinylidene fluoride emulsion, the emulsion particle size is 0.166μm, put it into the intermediate storage tank from the polymerization kettle, add water into the intermediate tank, the ratio of emulsion to water is 1:2, and transport it into the pipeline through the pipeline Type emulsifier, increase the rotational speed of the stator and rotor of the pipeline emulsifier to 10,000 rpm, open the outlet, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com