Preparation method of benzaldehyde

A technology of benzaldehyde and cinnamaldehyde, which is applied in the field of benzaldehyde preparation, can solve the problems affecting the purity and yield of benzaldehyde, and achieve the effects of novel technology, direct and fast separation, and green reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

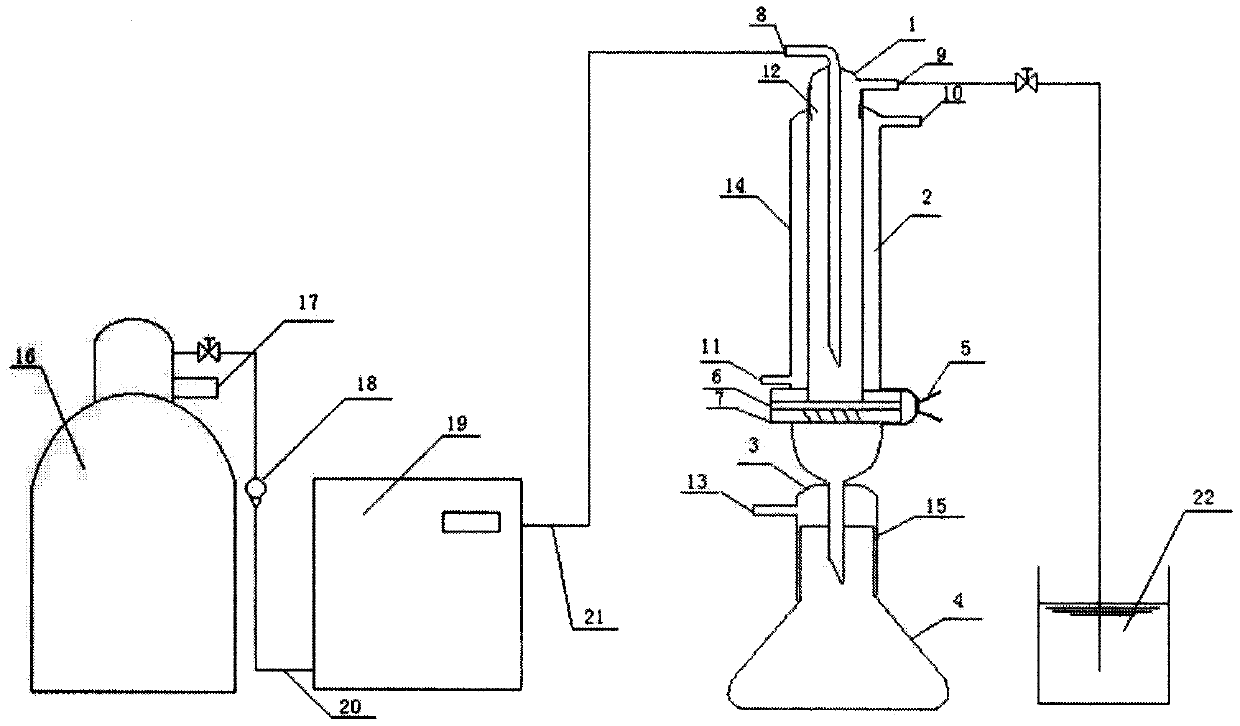

[0023] The preparation method of above-mentioned a kind of benzaldehyde, the reaction in the described ozonation reaction unit and the dewatering operation of dewatering device are carried out simultaneously, and process is as follows:

[0024] The oxygen of described oxygen cylinder 16 enters in the ozone generator 19 from the outlet pipe through the oxygen inlet 20 of the first pressure gauge 17, rotameter 18 and ozone generator 19; Ozone outlet 21 passes into ozone by the air inlet 8 of air guiding device 1, and the outlet pipe of air outlet 9 is directly inserted in the tail gas absorption tank 22; Under the catalysis of the catalyst, the reaction generates benzaldehyde; the water generated in the reaction process is pushed by the pressure of the vacuum pump connected to the air inlet 13, and flows through the filter membrane 6 and the sand core filter platform 7 into the receiving bottle 4, so as to achieve water and organic Product separation.

Embodiment 1

[0026] Taking cinnamaldehyde as raw material, load the mixed solution of 20.0g cinnamaldehyde and dehydrated alcohol into the ozonation reactor, the mass ratio of cinnamaldehyde and dehydrated alcohol is 1: 4, add the CaO catalyst of 3.0wt%, in- At 10°C, 0.05 g of ozone was injected per gram of cinnamaldehyde per hour to carry out ozonation reaction for 0.5 h. While reacting, the reaction product is dehydrated through the NaA type zeolite molecular sieve membrane in the water removal device of the ozonation reaction device with a pressure of 0.001 MPa, and the natural benzaldehyde with a purity of more than 85% is obtained after molecular distillation, and the yield is 65%. .

Embodiment 2

[0028] Taking cinnamaldehyde as raw material, load the mixed solution of 20.0g cinnamaldehyde and dehydrated alcohol into the ozonation reactor, the mass ratio of cinnamaldehyde and dehydrated alcohol is 1: 4, add the CaO catalyst of 3.0wt%, in- At 10°C, 0.95g of ozone per hour per gram of cinnamaldehyde was introduced to carry out ozonation reaction for 12.0h. While reacting, the reaction product is dehydrated through the PVA organic membrane with a pressure of 1.0 MPa in the water removal device of the ozonation reaction device, and the natural benzaldehyde with a purity of more than 85% is obtained after molecular distillation, and the yield is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com