Rapid formation method of lead storage battery

A formation method and lead storage battery technology, applied in the field of storage batteries, can solve the problems of long formation time and high energy consumption, and achieve the effects of short formation time, low energy consumption and saving charging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

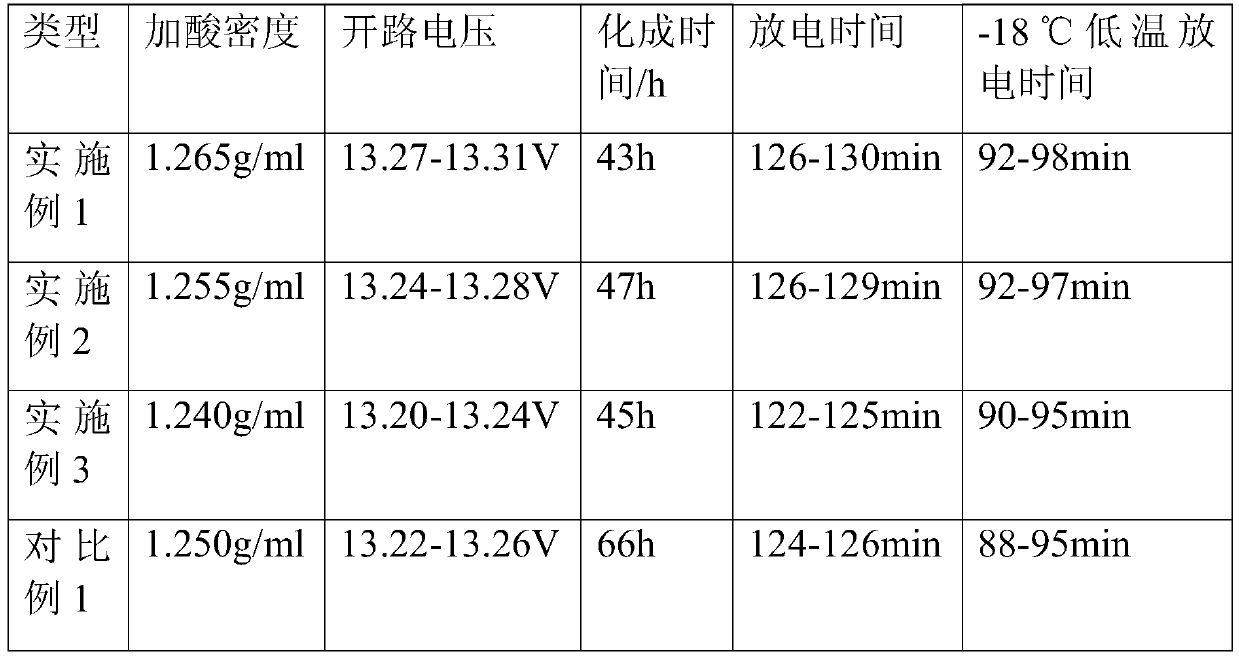

Embodiment 1

[0045] 12Ah battery

[0046] 1. The battery to be formed is automatically acid-added by a vacuum acid-adding machine, the density of the added sulfuric acid solution is 1.265 / ml, and the temperature is 12°C. Then stand in cooling water at 20°C for 0.5h to lower the internal temperature of the battery and at the same time allow the sulfuric acid electrolyte to permeate the plate.

[0047] 2. Place the battery in a constant temperature water bath at 33°C and let it stand for 20 minutes. After standing still, the internal temperature of the battery is more uniform, and the consistency of subsequent formation is better.

[0048] 3. Formation

[0049] a. The first charging and discharging: the charging current adopts the method of gradient increase and then gradient decrease. Then discharge with a large current until the voltage of the battery cell is lower than the specified value.

[0050] 0.08C current charging for 1h, 0.15C current charging for 2h, 0.25C current charging fo...

Embodiment 2

[0058] 20AH battery

[0059] 1. The battery to be formed is automatically acid-added by a vacuum acid-adding machine, the density of the added sulfuric acid solution is 1.255g / ml, and the temperature is 5°C. Then stand in 10°C cooling water for 1.0h to lower the internal temperature of the battery and at the same time make the sulfuric acid electrolyte soak into the plate.

[0060] 2. Place the battery in a constant temperature water bath at 35°C and let it stand for 30 minutes. After standing still, the internal temperature of the battery is more uniform, and the consistency of subsequent formation is better.

[0061] 3. Formation

[0062] a. The first charging and discharging: the charging current adopts the method of gradient increase and then gradient decrease. Then discharge with a large current until the voltage of the battery cell is lower than the specified value.

[0063] 0.08C current charging for 2 hours, 0.15C current charging for 2.5 hours, 0.25C current charg...

Embodiment 3

[0071] 12Ah battery

[0072] 1. The battery to be formed is automatically acid-added by a vacuum acid-adding machine, the density of the added sulfuric acid solution is 1.240g / ml, and the temperature is 15°C. Then stand in 10°C cooling water for 0.5h to lower the internal temperature of the battery and at the same time make the sulfuric acid electrolyte soak into the plate.

[0073] 2. Place the battery in a constant temperature water bath at 38°C and let it stand for 30 minutes. After standing still, the internal temperature of the battery is more uniform, and the consistency of subsequent formation is better.

[0074] 3. Formation

[0075] a. The first charging and discharging: the charging current adopts the method of gradient increase and then gradient decrease. Then discharge with a large current until the voltage of the battery cell is lower than the specified value.

[0076] 0.08C current charging for 1h, 0.15C current charging for 2h, 0.25C current charging for 5h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com